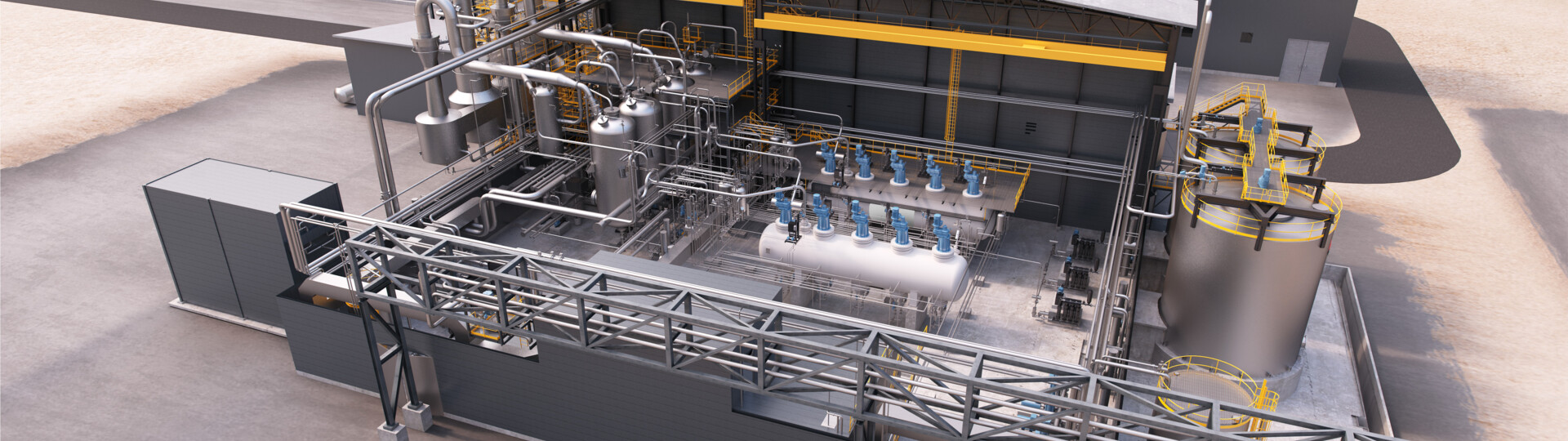

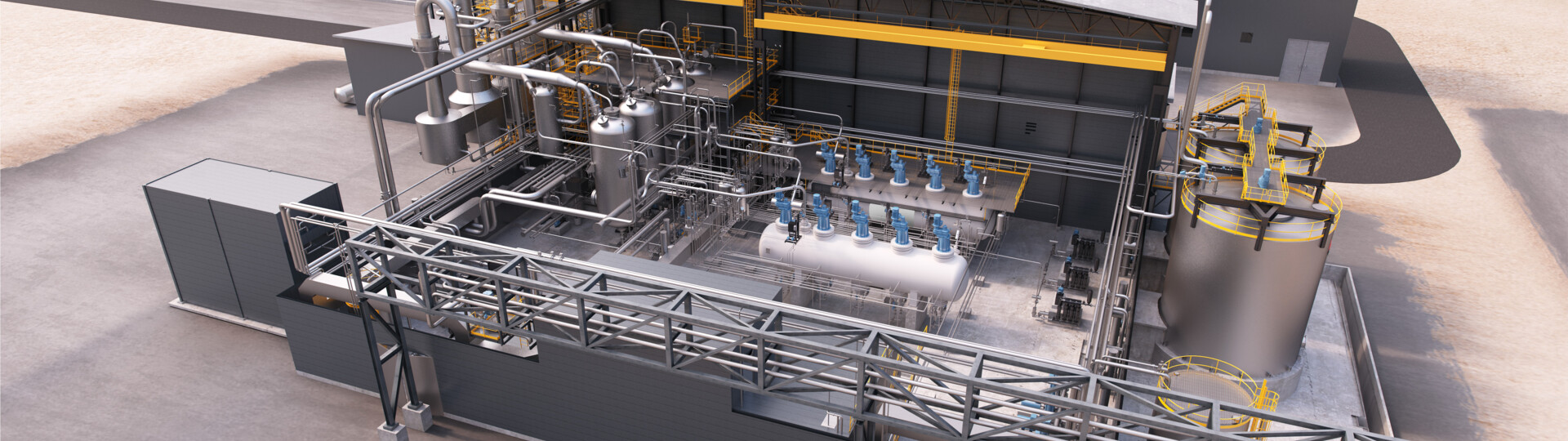

The autoclave feed tank with OKTOP agitators provides a controlled environment with sufficient storage and flexible live volume for smooth operation of the autoclave. The agitator is designed to provide a homogeneous slurry mixing and to ensure efficient operation. The solution is fed from the feed tank to the autoclave with feed pumps.

Over the past decades Metso has put substantial effort into improving the gas-liquid mass transfer rate in autoclaves in order to maximize both autoclave capacity and utilization of gaseous reagents. This increase has been achieved while still keeping the excellent solid suspension properties of the agitator intact.

Flash vessels decrease the pressure and the temperature of the slurry that comes out of the autoclave, slurry vaporizes partially in the lower pressure, and steam is directed to the preheater or to the gas cleaning scrubber. With the preheater, it is possible to collect excess heat energy to ensure a more sustainable product.

All exhaust gases are treated in the scrubber. An Metso ejector-Venturi scrubber is utilized to achieve good results with negligible pressure loss in the gas line. The scrubber is specially designed to operate in the autoclave process with attention paid to the high solids content sometimes present in the autoclave exhaust line.