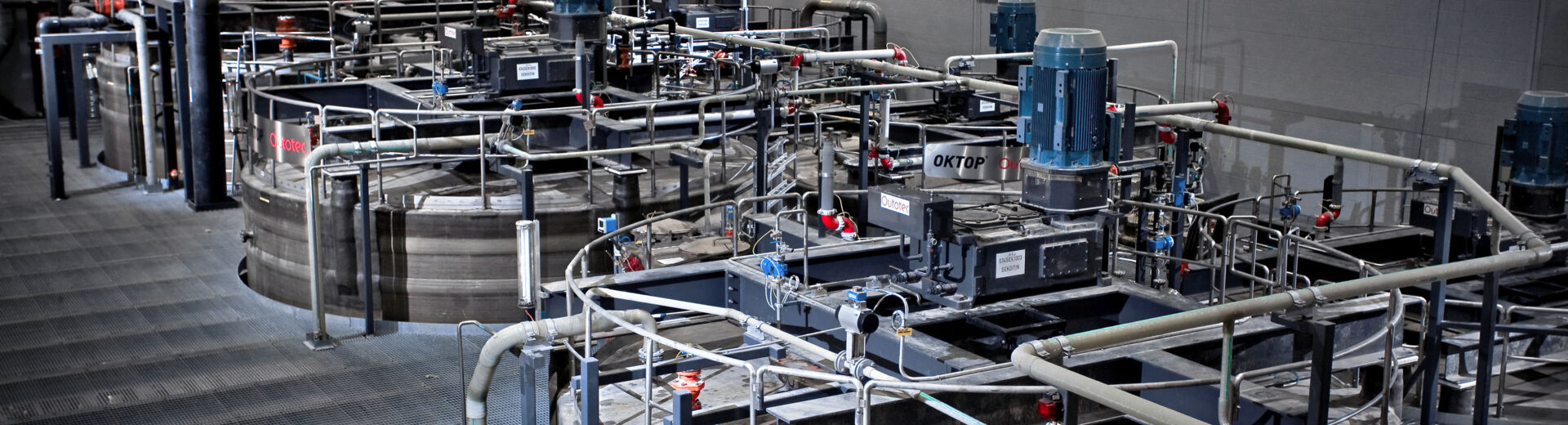

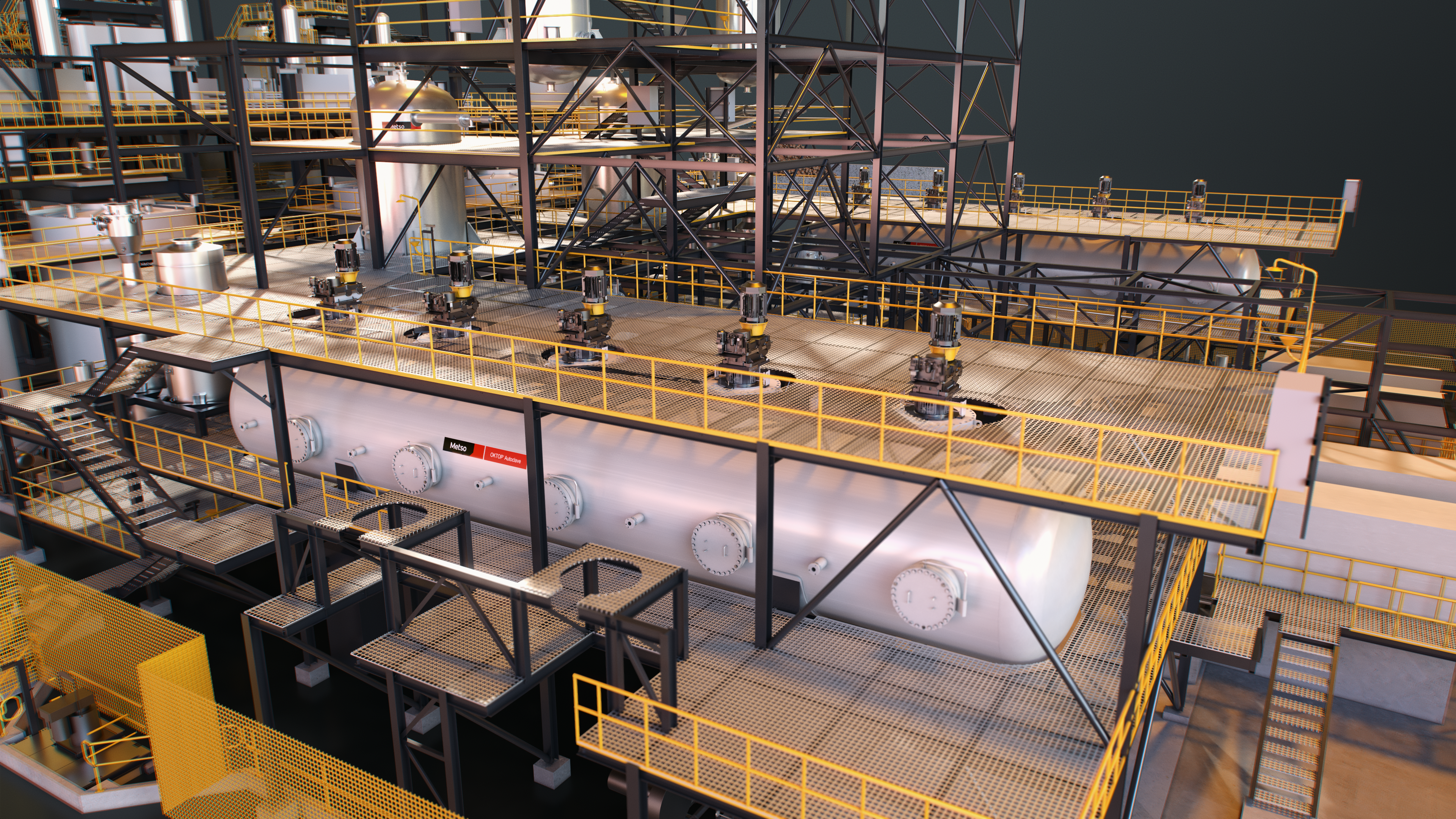

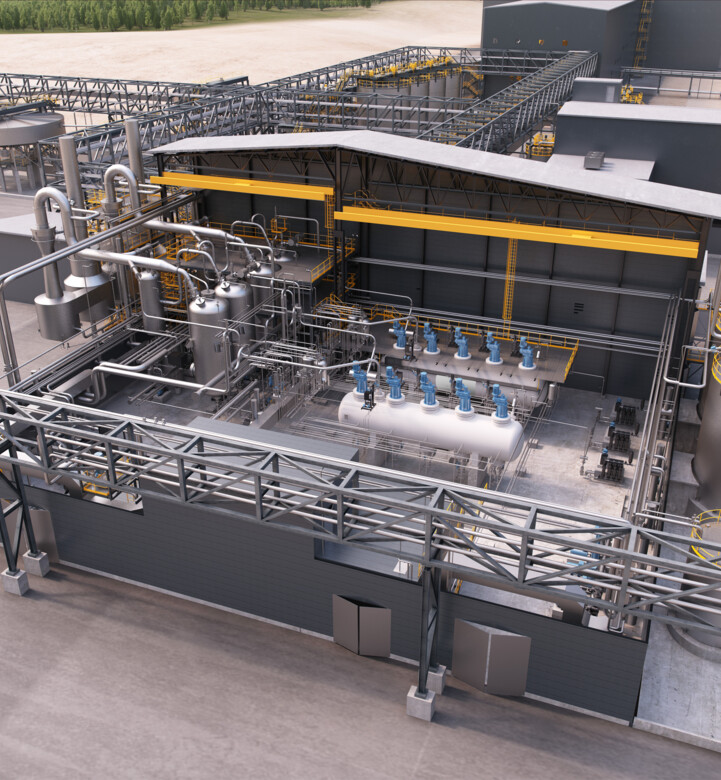

The slurry is fed into the tank by reagent feeds located at the top of the tank. An agitator designed for efficient solids suspension mixes the slurry. In some cases, excessive turbulence is generated to enhance process operation, for example, to wash particle surfaces to ensure better flotation. The conditioning tank is equipped with an uptake channel to prevent short circuiting of the solution and to ensure that even the largest particles are transported to the overflow outlet.

Multiple surface treatment options for the conditioner are available to meet different process conditions and to ensure stable and reliable operation.

The Metso OKTOP conditioner is also available with the innovative Metso SandSense sanding probe for advanced equipment control. The probe can notify operators if coarse material is starting to accumulate in the bottom of the tank. Accumulation of this type indicates that particles that are larger than specified are entering the tank and this may cause problems over time. By identifying this issue early, the problem can be resolved before it escalates.

Key features:

- Heavy-duty impeller design for durability and efficient mixing

- Sand gate for use during operational disturbances

- Uptake channel for smooth suspension transfer to flotation cells

- Easily accessible reagent feed pipes