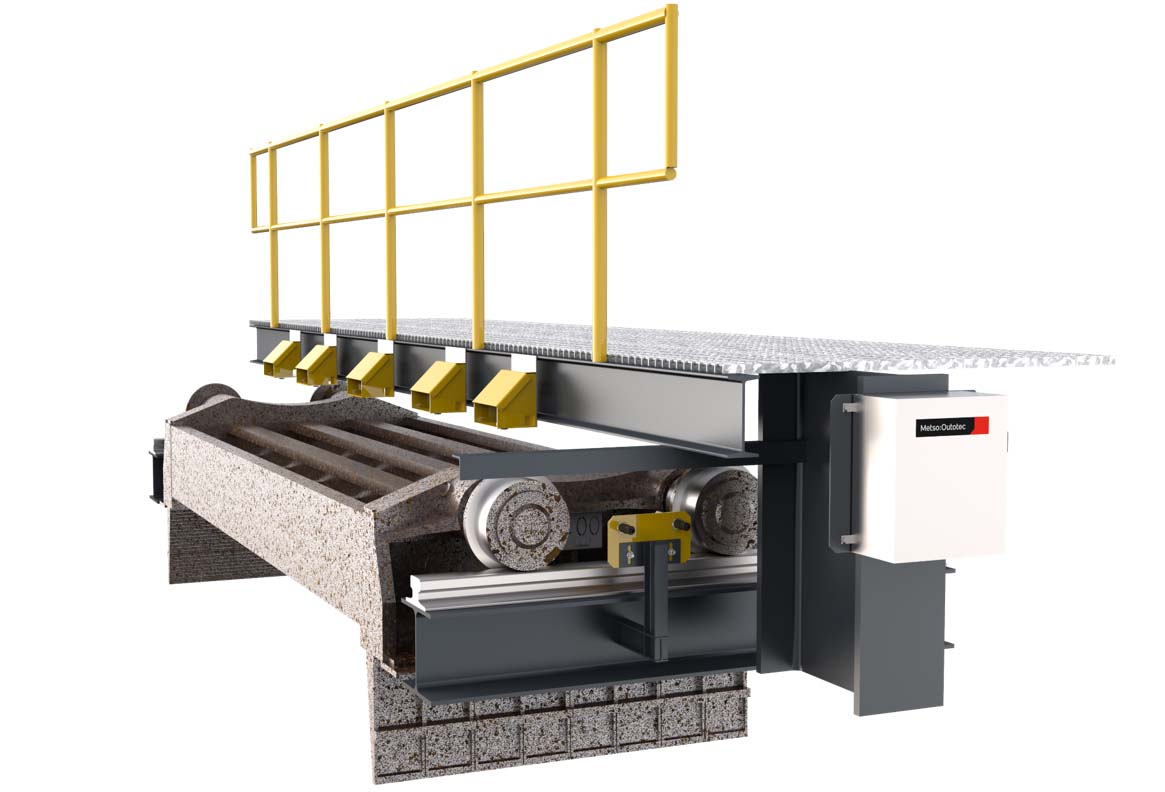

Process performance, stability and flexibility

Reduced fuel consumption and operation cost

Reduced CO₂ footprint

Operation insights and integrated best practices

• Increase gross pellet production by up to 5%

• Decrease thermal and electrical energy consumption by up to 5%

• Ensure operational stability to preserve lifetime of critical equipment

• Achieve consistent end product quality

• Increase plant safety

• Reduce the environmental impact of your operations

• React quickly to variations in upstream conditions or production targets

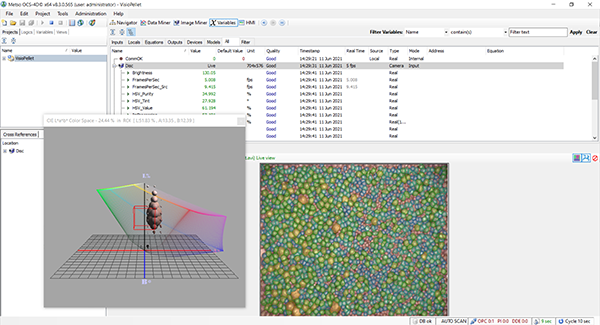

Metso’s Optimus™ Pellet advanced process control and expert system combines real-time plant measurements and unrivalled process know-how to make optimized operational decisions in everyday production.

This combination ensures operational stability, optimal plant operation and efficiency through automatic detection and correction of detrimental process deviations.

Optimus™ controls the main process inputs such as gas fans, dampers and temperatures profiles in order to ensure process stability, while maximizing pellet production, minimizing energy consumption and maintaining consistent product quality.