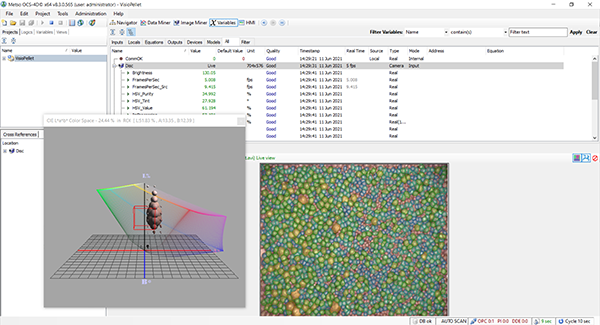

Improve reactive and preventive maintenance planning and execution with accurate, real-time monitoring of pallet car condition

Minimize downtime and optimize spar epart ordering with easy integration of pallet-car operation and maintenance data into the plant control and maintenance systems

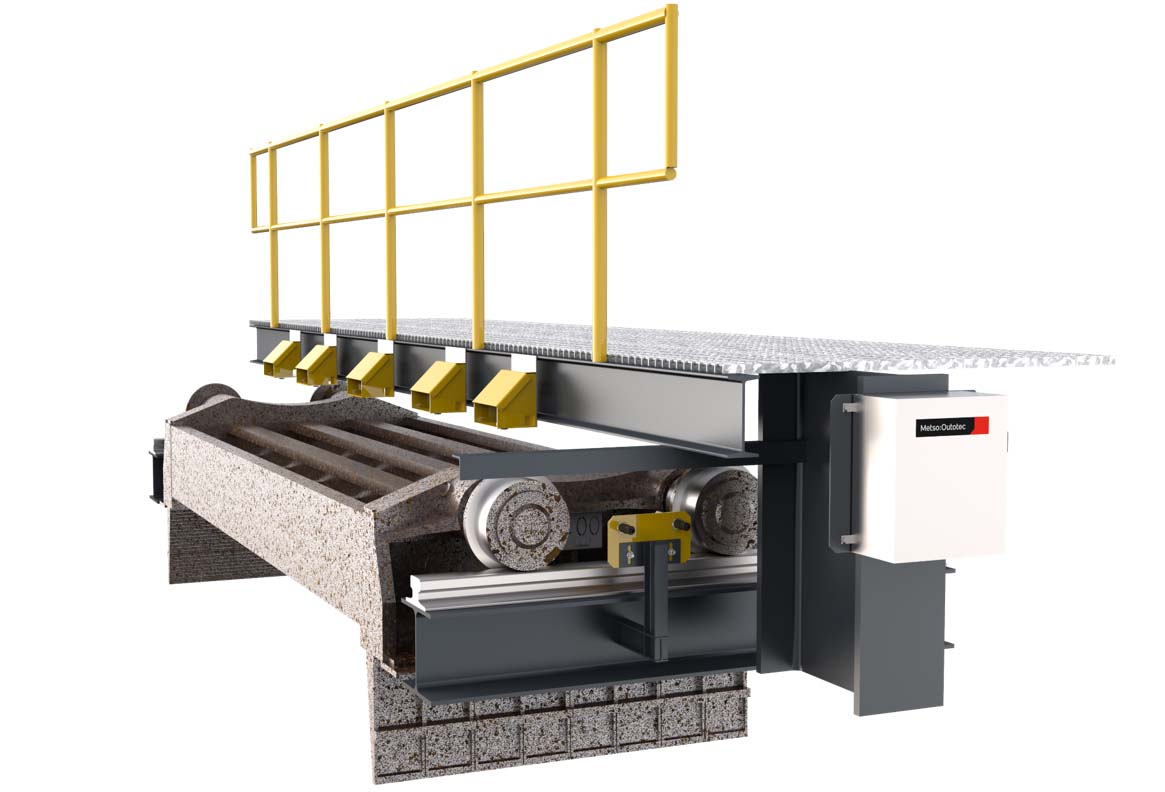

Optimize the process performance of the travelling grate thanks to improved gas permeability of the pellet bed and improved sealing

This system provides online measurement of pallet car deflection using contactless sensors in addition to tracking the pallet cars that are in operation. This enables center castings to be replaced at the optimal time, significantly extending equipment lifetime. The system can also detect cars with missing wheels or grate bars and includes a pallet car identification system with optical cameras or RFID technology.

The system provides a highly accurate overview on the condition of every single car, supporting the planning and execution of preventive maintenance on these key pellet furnace components. This helps to improve overall plant performance, extend the lifetime of equipment, and reduce maintenance and spare-part costs.