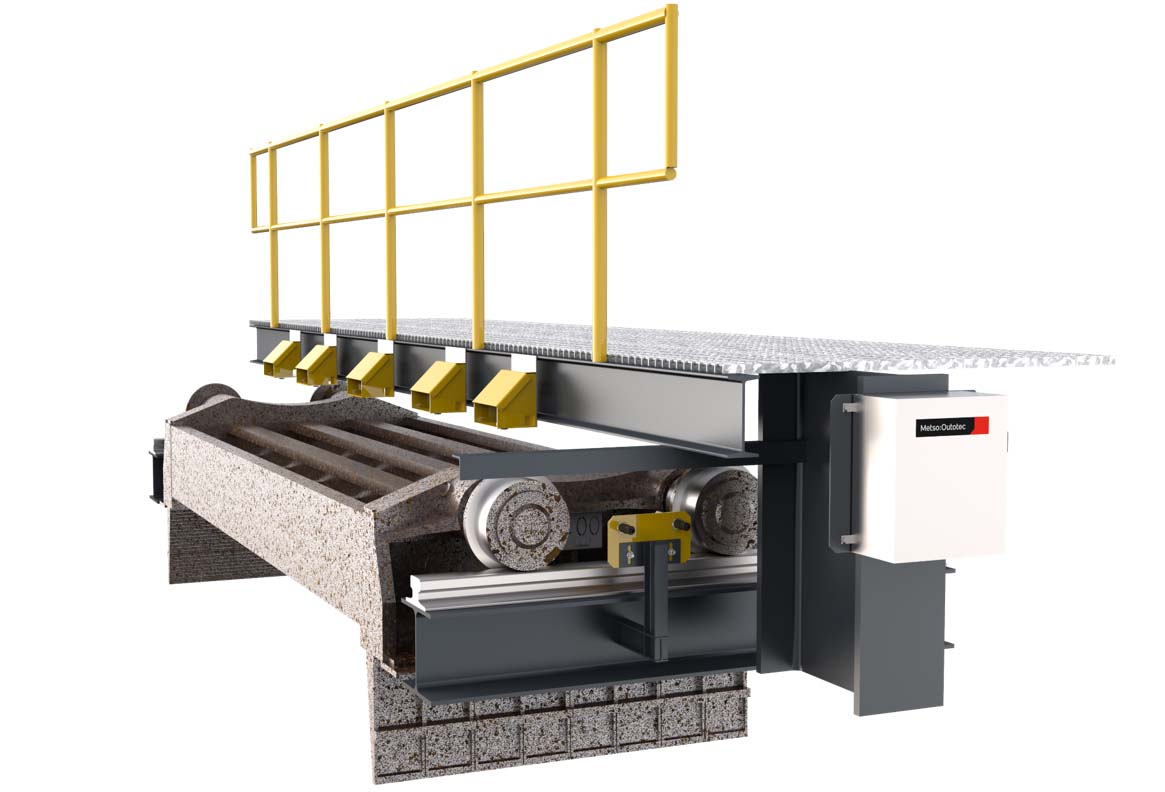

We have a proven design of traveling grates for sinter and pelletizing plants with over 100 plants and 18,000 pallet cars delivered over the last 50 years. Based on the unparalleled sintering and pelletizing process know-how of the technology leader with an in-house R&D center, engineering, and control of manufacturing from a single source. The continuous development of pallet cars for new plant projects worldwide as well as of the related global supply base lead to the highest performance with regard to the total cost of ownership, maintainability, and availability.

Spare part packages can be tailored according to customer requirements

- Center and end castings

- Bearings and pressure rollers

- Complete roller sets

- Grate bars

- Sidewalls

- Sealing elements

- Front plates

To reduce the wear, maintenance and spare part costs of the traveling grate system, it is imperative that all pallet cars are perfectly uniform in accordance with the main components of the gear rims and curved rails of drive and tipping station as well as the run and slide rails. As the OEM supplier, we deliver all key spare parts and support with expert services including inspections and the alignment of the traveling grate.

- Proven design with tens of thousands of pallet cars delivered over many decades

- Long lifetime of about 25 years in normal operating conditions

- Based on unparalleled sintering and pelletizing process know-how, from a technology leader with own R&D center

- Continuous development of pallet cars within new plant installations worldwide

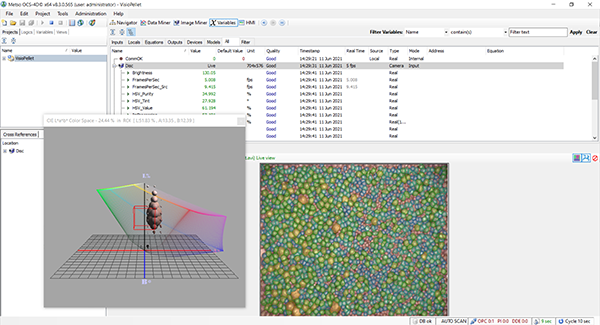

- Easy component identification and purchasing with Metso eCatalogue

- Proven quality assurance/quality control (QA/QC) procedures