Maximized underflow density

Increased beaching angle at tailings deposition

Consistent performance in changing process conditions

Up to 40% reduced water usage compared to conventional thickeners

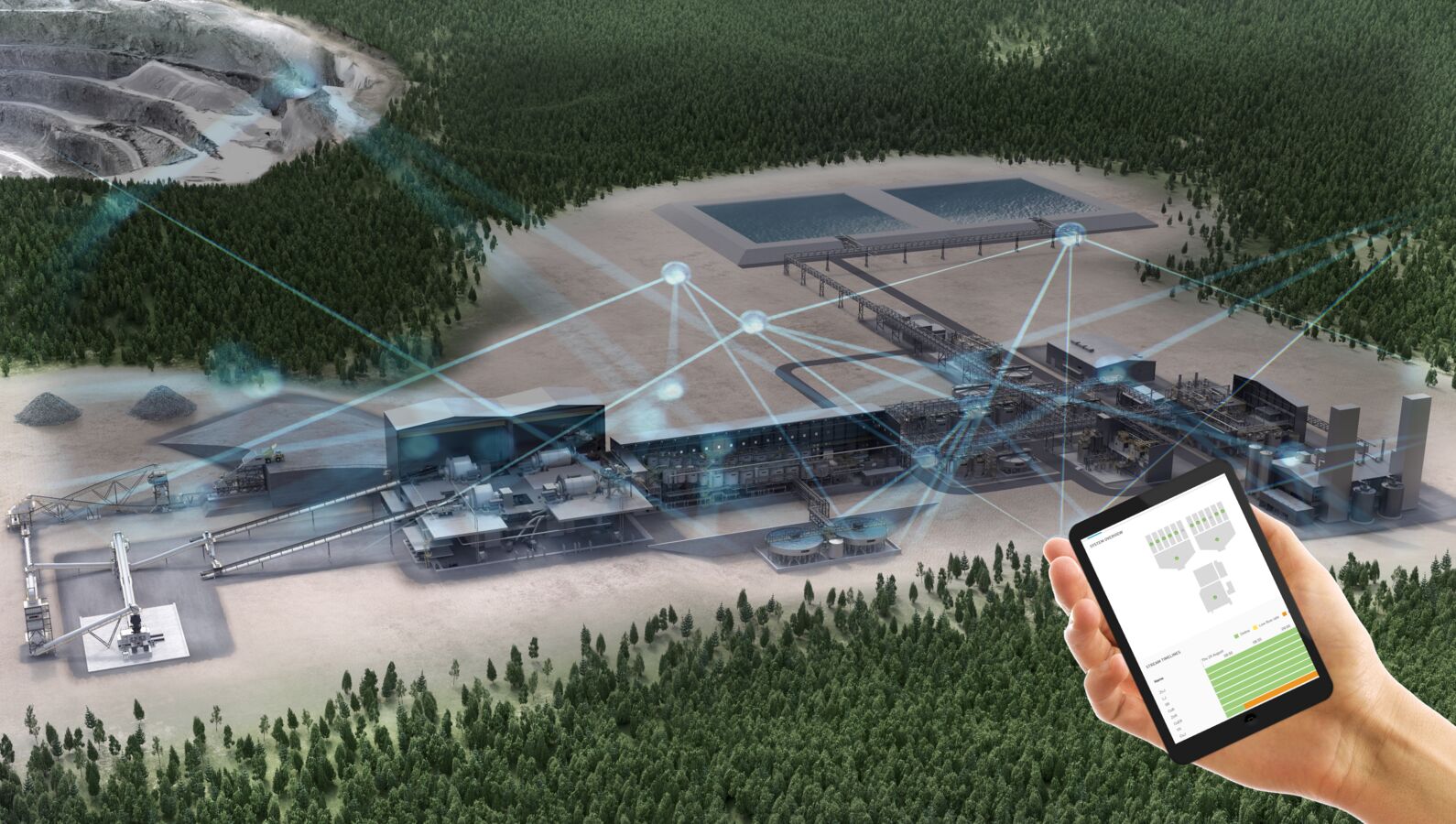

Supporting your operations, from plant design expertise to equipment, parts and services for every stage of your process.

Are you looking to increase production, reduce risks, lower operating costs and enhance environmental performance? Then you are in the right place.

From the design and supply of products for a greenfield plant, to the addition of a single machine for an existing production line, we are here to help.

Rely on OEM experts because not all parts are created equal. Spare and wear parts built to perform.

Helping you get the most out of your equipment and processes.

Maximized underflow density

Increased beaching angle at tailings deposition

Consistent performance in changing process conditions

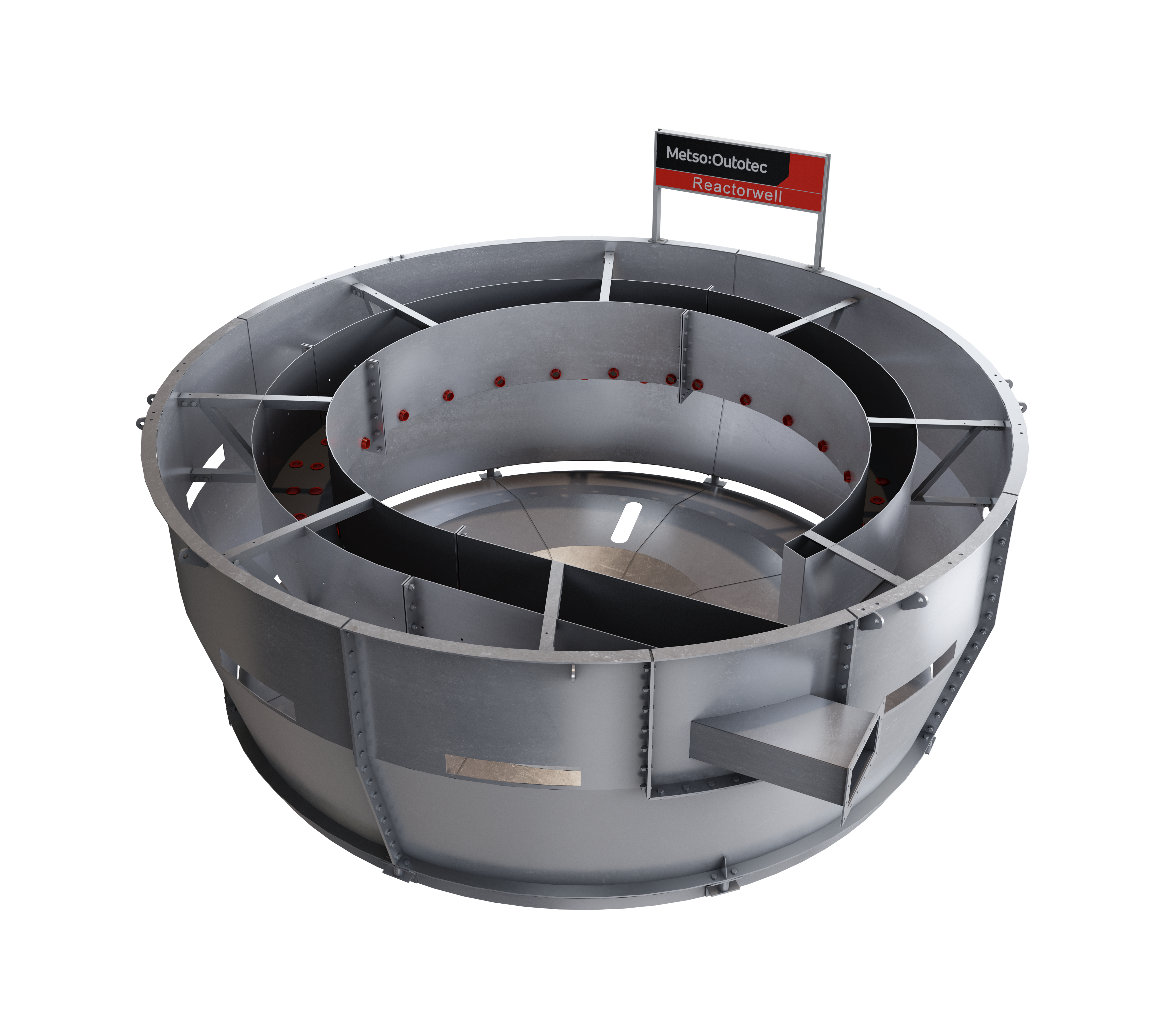

Metso and its legacy companies have already installed more than 100 Paste Thickeners worldwide. The thickener utilizes control based on consistent solids inventory to achieve and maintain the required underflow density.

The Paste Thickener is best suited to applications requiring a high degree of dewatering, such as:

Metso is the global leader in the design, fabrication and supply of thickening and clarifying solutions with more than 50 years of experience. Our leading process expertise and know-how covers a wide range of applications with sustainability at the forefront.

A key feature of the Paste Thickener is Vertical Load Monitoring via SmartRake – one of the only systems in the world able to detect early formation of rotating beds. Tank mounted bed mass sensors can’t detect these loads.

By incorporating Vertical Load sensing with plant process data into the Thickener Optimizer Control system the solids inventory within the tank can be maintained at a consistent loading. The Operator now has another view of what’s happening inside the tank. This leads to more consistent underflow density and reduced downtime.

With the SmartRake system, individual hydraulic cylinders are monitored and actively adjusted to maintain alignment of the rake mechanism.

Autodill™

Turbodill™

Thickener optimizer