Battery Minerals

Metso is driving a more responsible and sustainable energy transition with its comprehensive coverage of the battery minerals production and recycling processes.

Supporting your operations, from plant design expertise to equipment, parts and services for every stage of your process.

Are you looking to increase production, reduce risks, lower operating costs and enhance environmental performance? Then you are in the right place.

From the design and supply of products for a greenfield plant, to the addition of a single machine for an existing production line, we are here to help.

Rely on OEM experts because not all parts are created equal. Spare and wear parts built to perform.

Helping you get the most out of your equipment and processes.

Proprietary technology including OKTOP® pCAM reactor, thickeners, filters, analyzers to form core of the process

Low energy and water consumption with Metso technology

In-house process development, pilot and bench scale plants for testing

Growing emphasis on high performance batteries driving the demand for high quality precursor materials

Precursor is critical to battery performance and safety

Growing demand for sustainable precursor materials to address environmental impact and social responsibility in supply chain

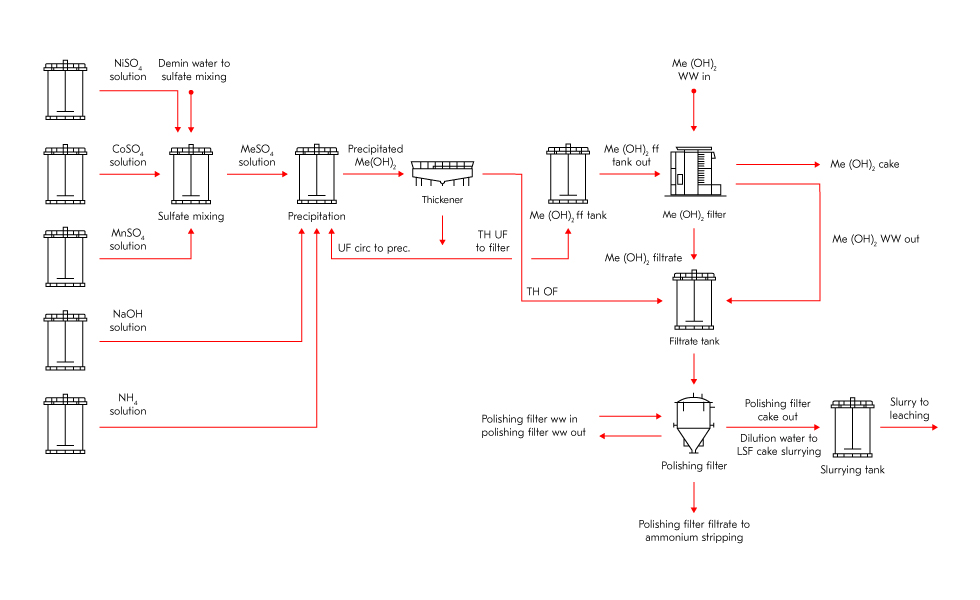

Centred around OKTOP® pCAM reactor, PSI® 1000 particle size analyzer, and pCAM process control, Metso’s pCAM plant integrates advanced technology and decades of know-how to ensure an energy-efficient and sustainable process. Backed by world-class research & and testing capabilities, Metso’s pCAM plant is an integrated solution for all co-precipitated chemistries.

Core attributes

We have the robust proprietary technology, knowhow and insight needed to help improve the efficiency and sustainability of the entire lithium hydroxide value chain. The modular plant design can also be tailored according to specific requirements.

| Core | Ancillary | Enablers | Services |

| OKTOP® pCAM reactor | MHC™ hydrocyclones | PSI® 1000 particle size analyzer | Lifecycle services |

| LSF filter | Samplers | Courier® HX analyzer | Basic engineering services |

| Larox® PF filter | Metso pCAM field instrumentation | Geminex™ metallurgical digital twin | Project maintenance services |

| Larox® RT filter | Batch and pilot testwork | Study services | |

| Thickeners and settlers | Metso pCAM process automation | Equipment inspections | |

| OKTOP® ventilation gas scrubbers | |||

Simulation based LCIA (Life Cycle Impact Assessment) by Metso

Key findings:

OKTOP® pCAM reactor: