Reaching your sustainability targets?

Find out how our filtration services help to achieve your sustainability targets

Supporting your operations, from plant design expertise to equipment, parts and services for every stage of your process.

Are you looking to increase production, reduce risks, lower operating costs and enhance environmental performance? Then you are in the right place.

From the design and supply of products for a greenfield plant, to the addition of a single machine for an existing production line, we are here to help.

Rely on OEM experts because not all parts are created equal. Spare and wear parts built to perform.

Helping you get the most out of your equipment and processes.

Adjustable, pressurized spray nozzles ensure quick cleaning

Removes harmful build-up on filter cloths, bearings, rollers and plates

Removes harmful substances, slurry spills and solid materials on the filter

The washing sequence is automated and programmable according to application requirements

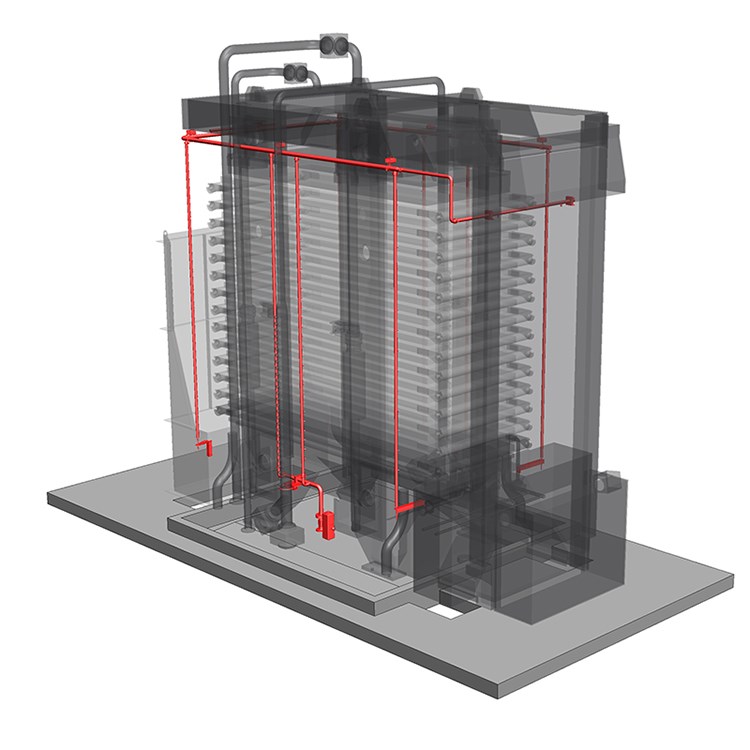

The PF external CIP washing system is a fixed spray bar system on the PF filter that operates in sequences during the filtration cycle or can be operated manually before maintenance to clean parts that are difficult to reach.

The CIP-washing upgrade is compatible with all PF filters.

Leaking collectors and cake discharge may cause solids build-up in the filter causing wear or damage to certain parts. The CIP-washing system removes build-up which increases the lifetime of filter cloths, bearings, rollers, and plates. Clean filters also decrease maintenance shutdowns and spare part consumption and increase operational safety.

Should an application use harmful material would need to be washed away from all surfaces. Maintenance on the filter unit is safer and more user-friendly when using the CIP-washing system as there are fewer slurry spills or solid material on the filter and maintenance platforms.

After the cake discharge, an automatic valve in the CIP-piping opens and the washing system turns on. The piping has been designed to operate at a pressure of 16 bar, although the average operating pressure is about 10 bar. There are several hundred adjustable spray nozzles in CIP-piping to ensure thorough cleaning of the entire filter.

The washing sequence can be automated or operator-controlled and programmable according to customer requirements. The washing time depends on the application and sump capacity on the floor. An average washing time ranges from 30 seconds to one minute.

The amount of water used is 300-800 L/min depending on filter size. When the CIP washing stage is complete, the filter automatically returns to standard operation.

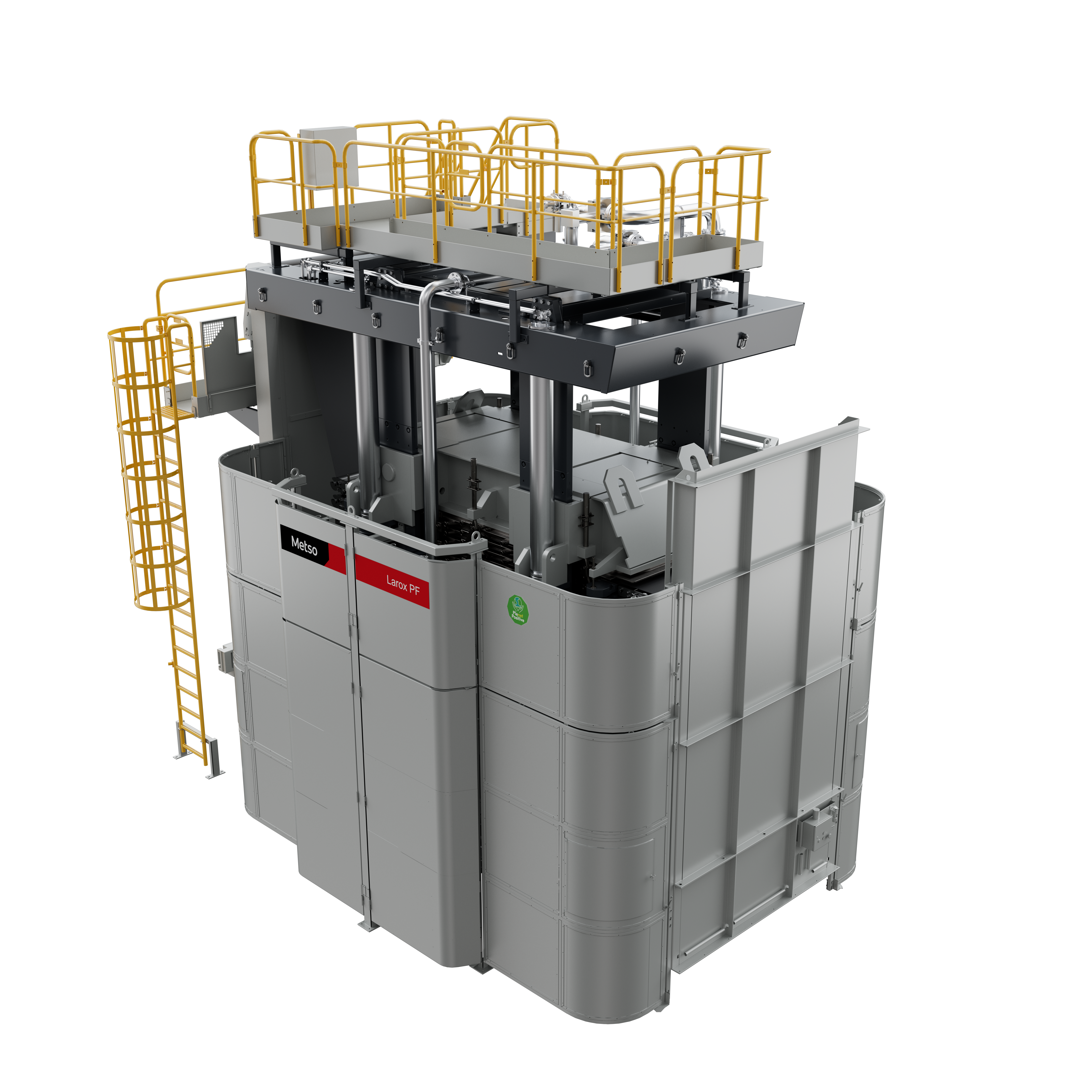

The CIP-washing system is compatible with all standard installations of the following Metso Larox PF filters:

The PF external CIP washing system has different variations for all PF series filters.

Depending on the structure it can be used with the plate pack open or closed. Different frame sizes also influence the structure.