Reaching your sustainability targets?

Find out how our filtration services help to achieve your sustainability targets

Supporting your operations, from plant design expertise to equipment, parts and services for every stage of your process.

Are you looking to increase production, reduce risks, lower operating costs and enhance environmental performance? Then you are in the right place.

From the design and supply of products for a greenfield plant, to the addition of a single machine for an existing production line, we are here to help.

Rely on OEM experts because not all parts are created equal. Spare and wear parts built to perform.

Helping you get the most out of your equipment and processes.

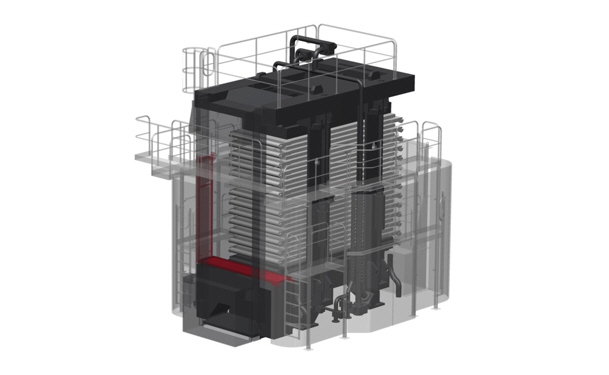

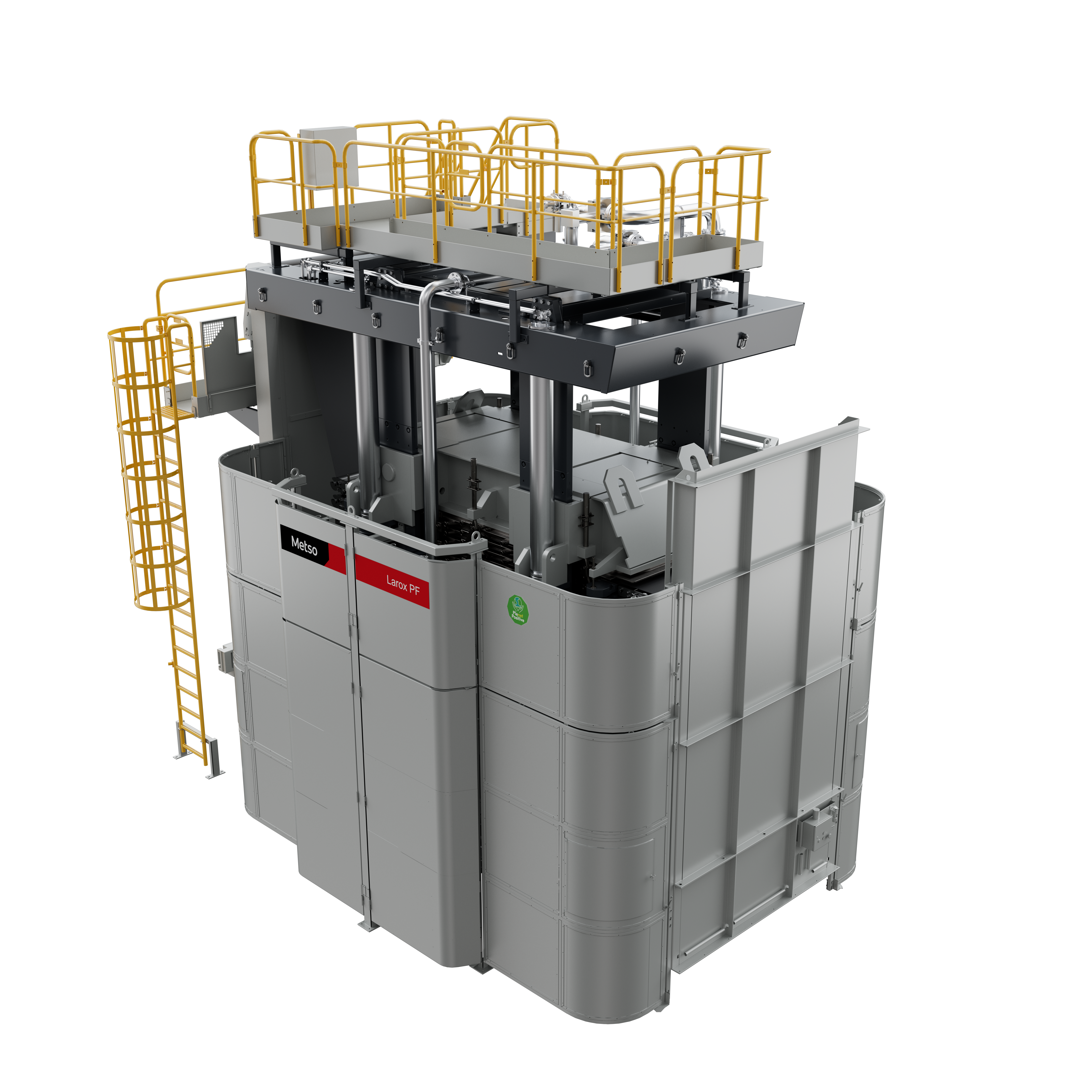

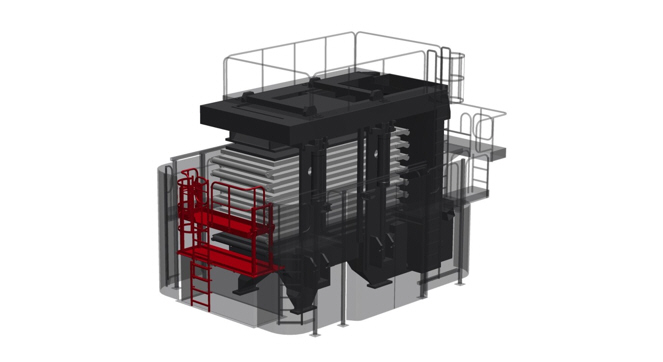

Performing maintenance on the filter requires access over the front and rear cake chutes. This is currently performed by erecting scaffolding which takes about 6 hours to assemble and a further 2 hours to disassemble. Planning beforehand is also required as well as additional scaffolding crew before the maintenance can take place. The maintenance procedure requires the filter to be shut down for at least 10 hours leading to production losses.

The design of our service platform decreases maintenance time and labour drastically with the following features: