Metso has enhanced its pinion condition monitoring protocol with infrared sensors and a thermographic camera to provide accurate temperature outputs across the tooth profile. The pinion temperature monitoring system delivers precise information about the pinion and ring gear system operating condition by measuring temperature readings at the drive end, non-drive end and across the entire pinion width.

Prior to online monitoring equipment, an operator would use an infrared measurement device to manually read the temperature across the pinion width. This labor-intensive process was subject to consistent measurement location and operator reading frequency. Pinion temperature monitoring using infrared sensors together with a thermographic camera provides a proactive condition-based maintenance approach to help increase productivity, reduce downtime and maximize assets' useful life.

The pinion temperature monitoring system provides real-time operating information, which is a valuable resource when planning a maintenance program, from repair work to successful proactive maintenance. The pinion temperature monitoring system is a very efficient upgrade, and easy to integrate into the site DCS and mill control panel/PLC.

Unplanned equipment downtime can cause severe financial losses, but the pinion temperature monitoring system allows operators to minimize unplanned stoppages. This ensures optimum and efficient management of maintenance and preparation to forecast shutdown time. The pinion temperature monitoring system allows for planned maintenance that can help to avoid emergency shutdowns.

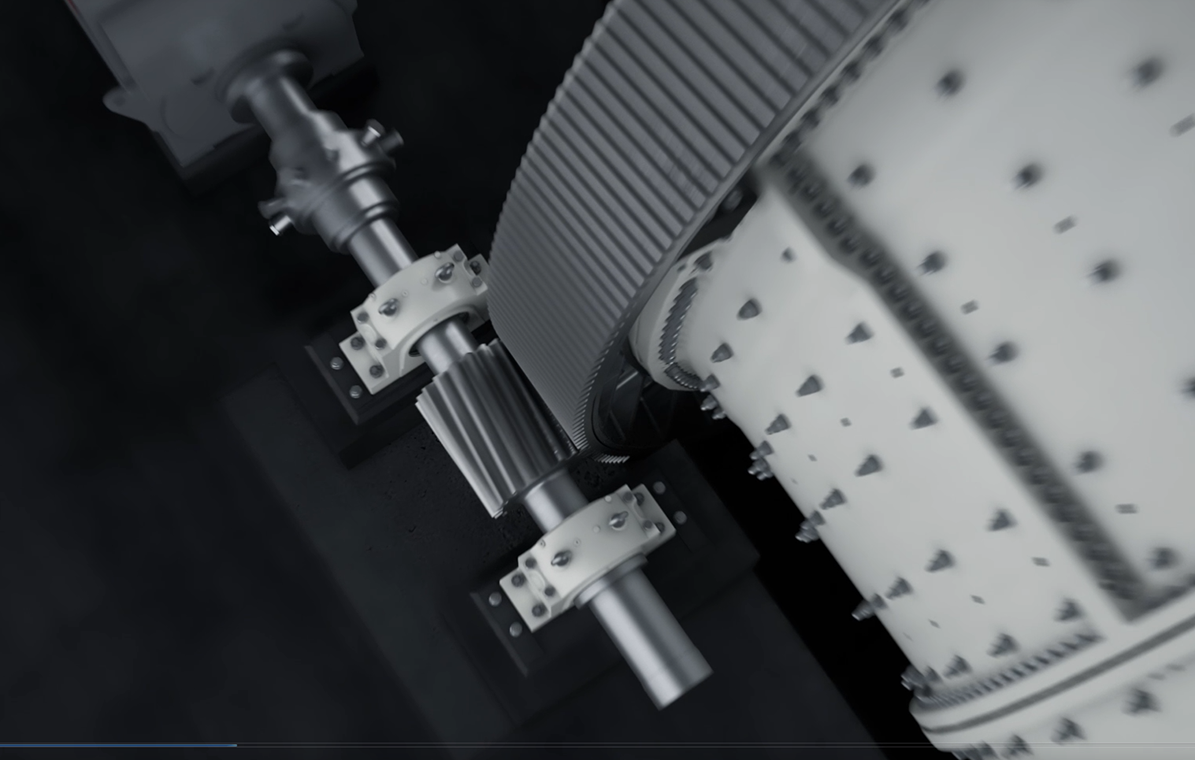

The pinion temperature monitoring system allows the operator to monitor temperatures across the pinion profile. Depending on the pinion width, two or three infrared sensors are positioned alongside the thermographic camera to cover the entire profile. These sensors provide signals to the control system about the absolute temperature of the pinion at each device location and the control system calculates the temperature differentials between the devices.

The sensors are located conveniently for maintenance and contained in tubes to avoid lubricant spray, which could inhibit accurate readings.

The pinion temperature monitoring system is an excellent indicator of various critical pinion related factors, including:

- State of gear set alignment

- Sufficient lubrication

- Quality of lubrication

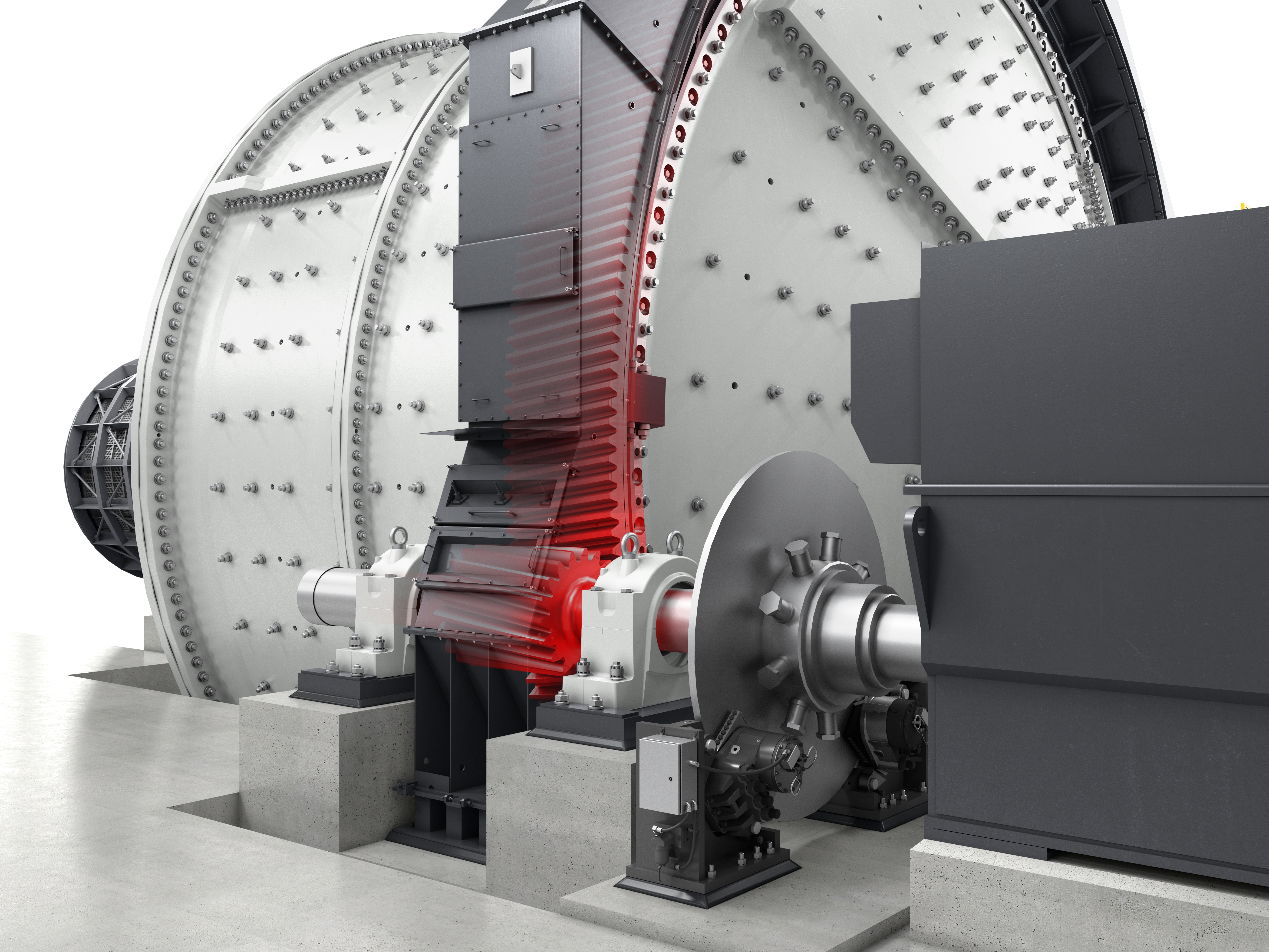

The pinion temperature monitoring system can be easily installed on any horizontal grinding mill equipped with a pinion and ring gear. Metso offers a complete installation package, including the support bracket assembly, infrared sensors, thermographic camera, air filter regulator and purge, junction box, documentation and optional installation and supervision.

Download the leaflet >>