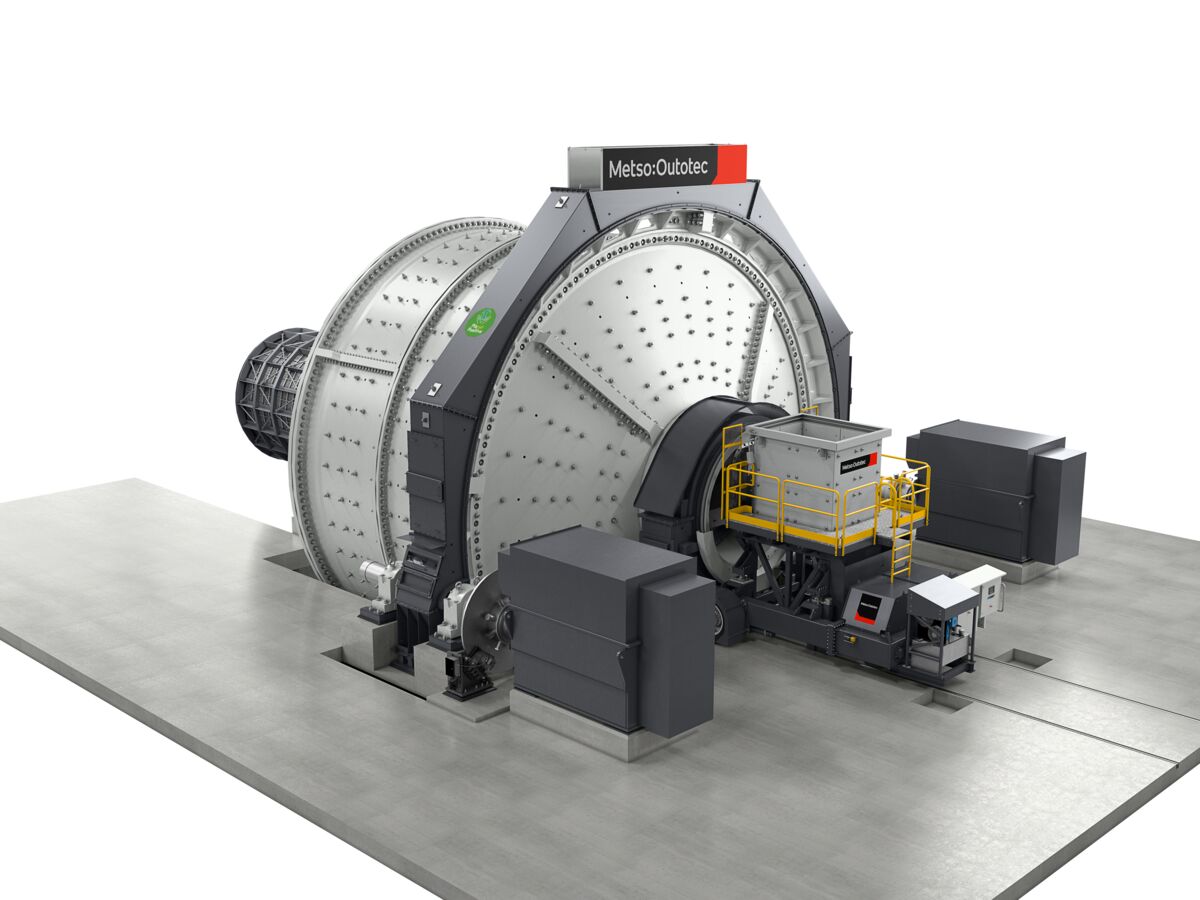

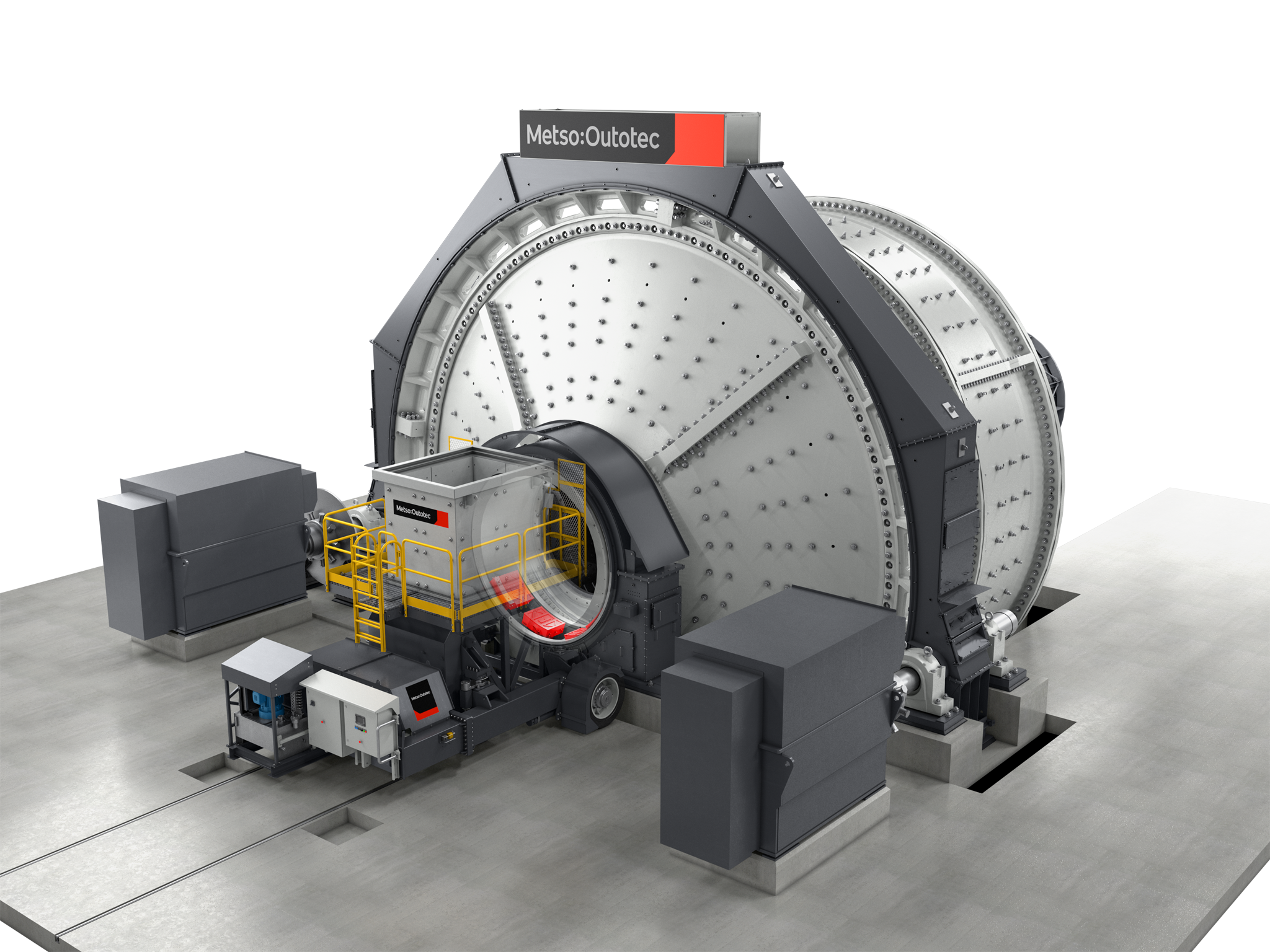

Engineered to excel

Metso Premier™ horizontal grinding mills bring together limitless possibilities in design and unmatched performance to exceed your operational goals.

Supporting your operations, from plant design expertise to equipment, parts and services for every stage of your process.

Are you looking to increase production, reduce risks, lower operating costs and enhance environmental performance? Then you are in the right place.

From the design and supply of products for a greenfield plant, to the addition of a single machine for an existing production line, we are here to help.

Rely on OEM experts because not all parts are created equal. Spare and wear parts built to perform.

Helping you get the most out of your equipment and processes.

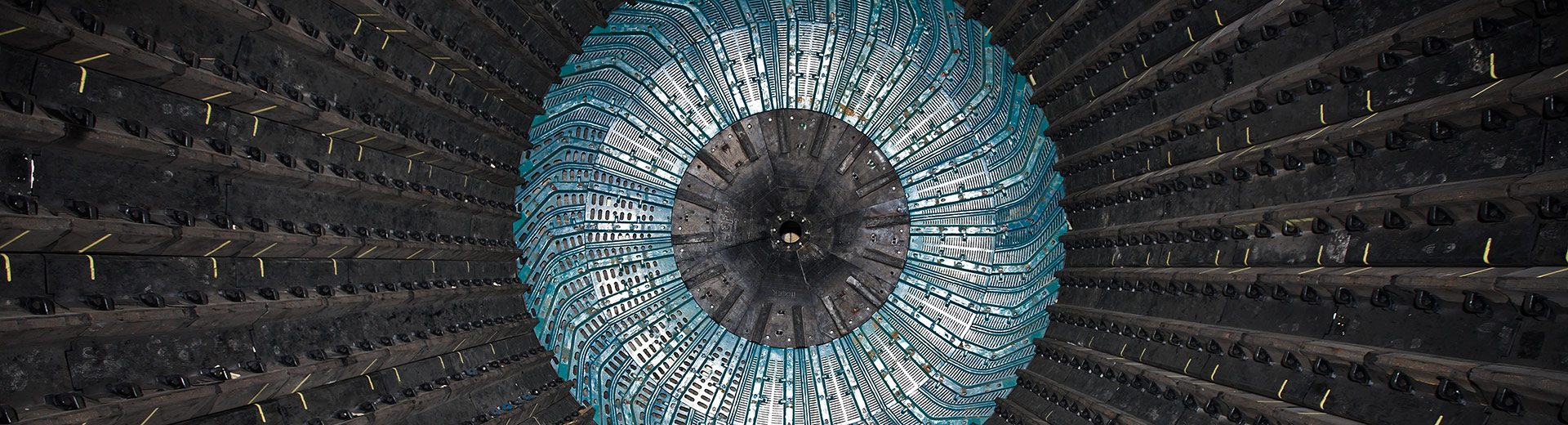

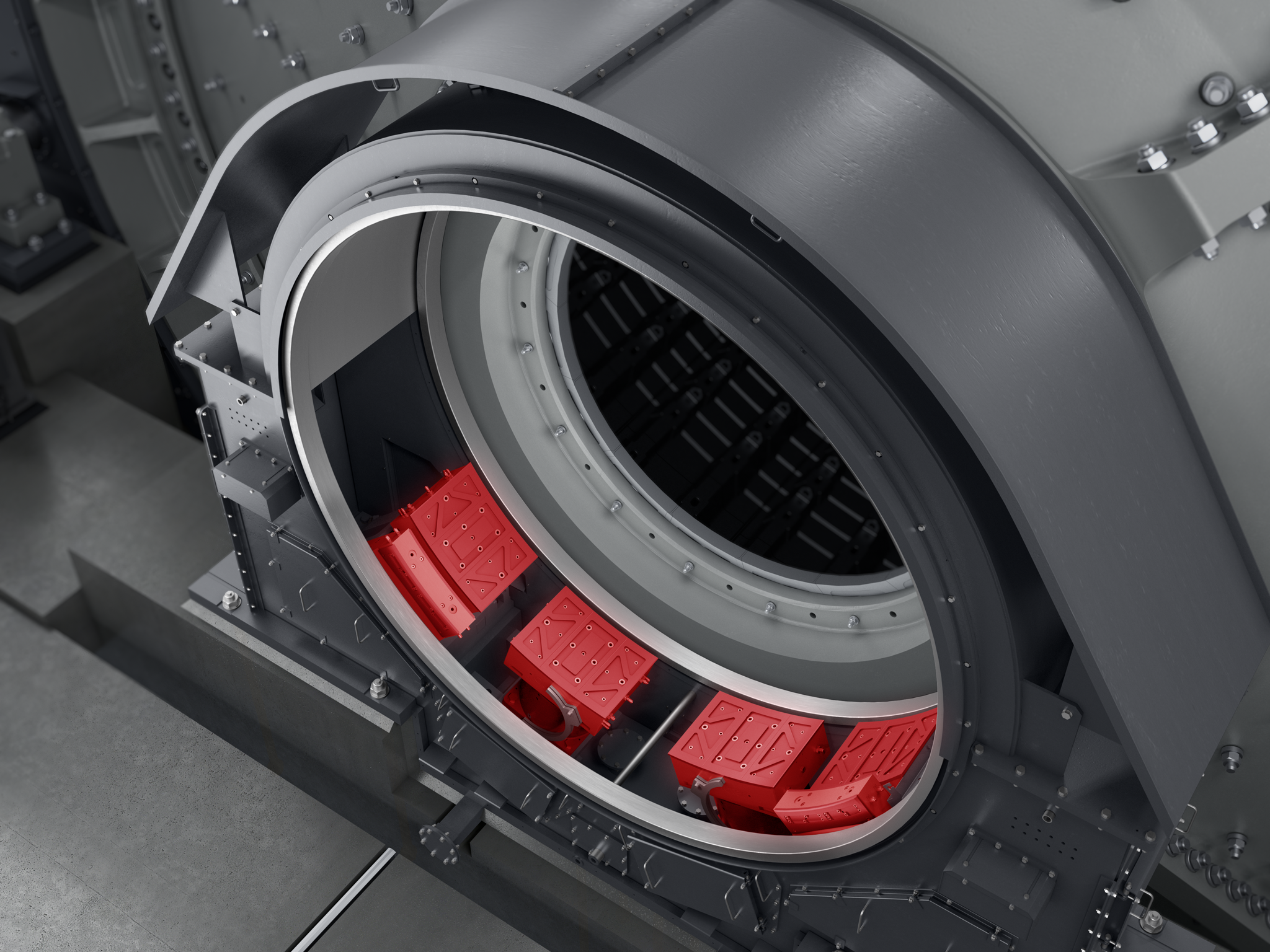

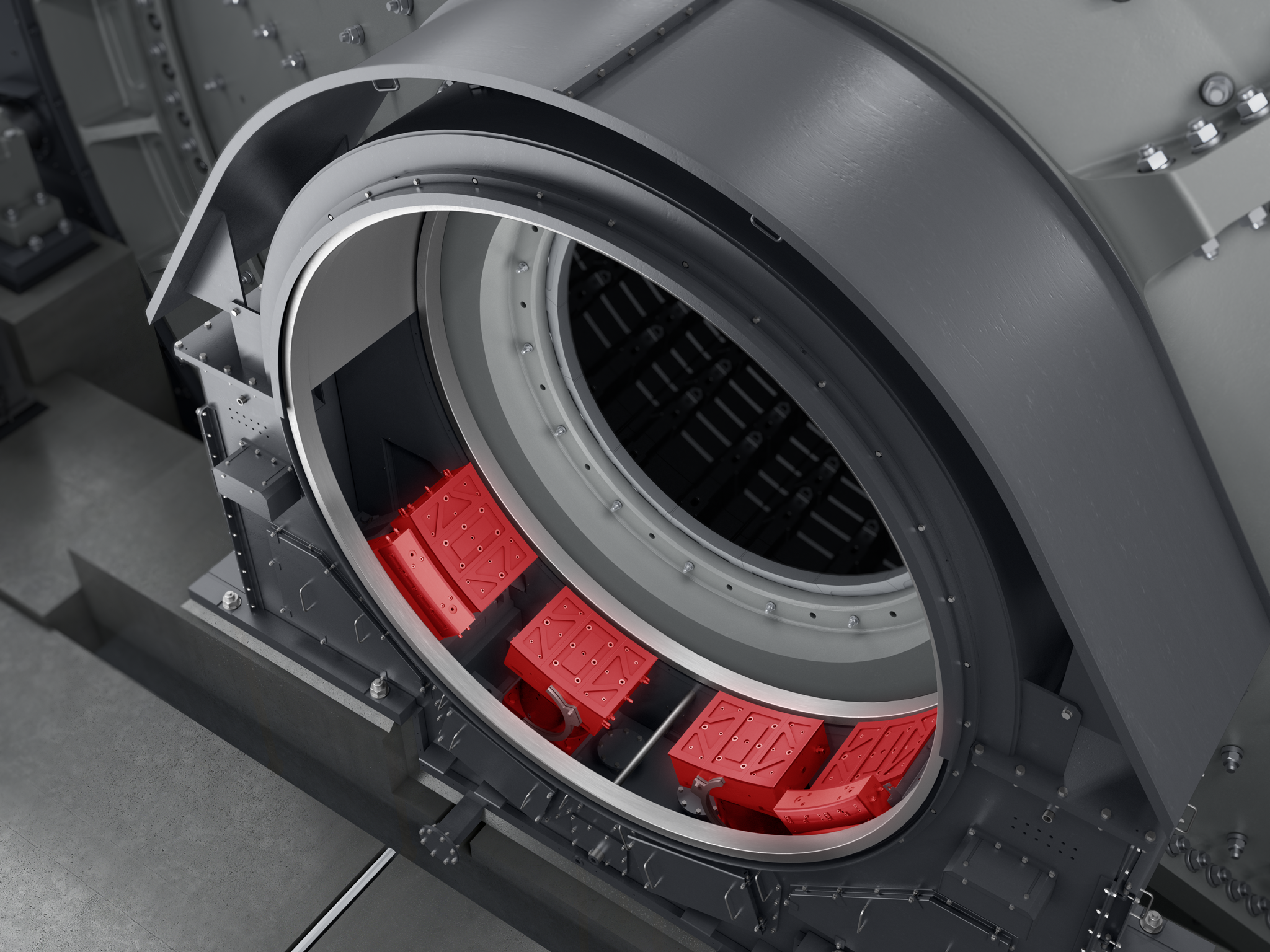

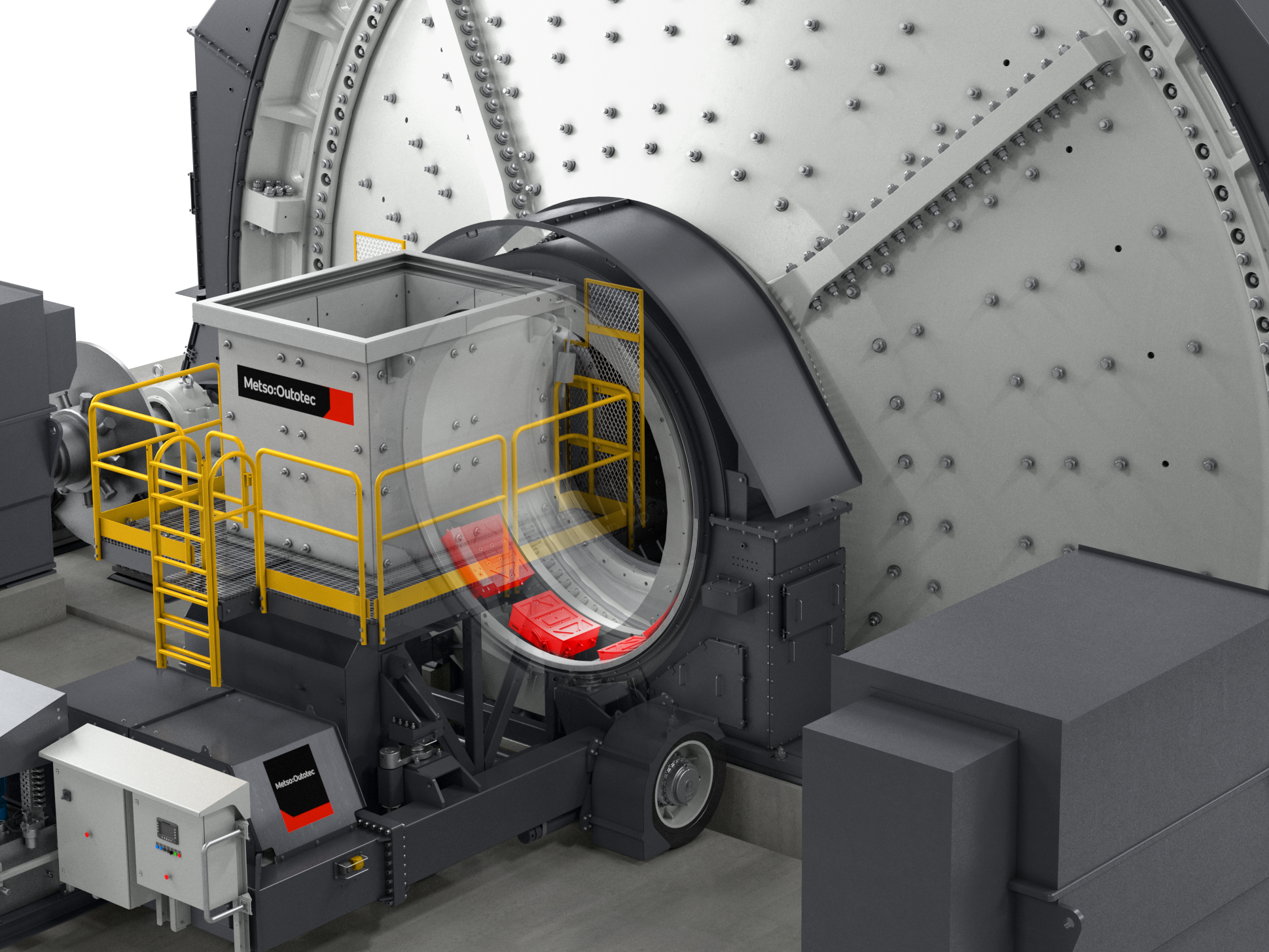

The Metso Polymer HSB system ensures optimal performance of your grinding mill. The system improves the durability and serviceability of both radial and axial hydrostatic bearing pads compared to bronze or white-metal pad bearing systems, thereby eliminating unplanned shutdowns due to bearing failure.

Bearing lubrication system and/or bearing pad failure is a common cause of mill stoppages and can result in costly damage to the mill-side bearing journal. The Polymer HSB system eliminates failures and unscheduled downtime associated with surface-to-surface contact caused by journal defects, lock-charge starts, or hydraulic system failures. It uses a specially developed polymer pad material to ensure smooth operation even in the most difficult operating scenario.

All new Metso grinding mills are fitted with the Polymer HSB system. The Polymer HSB system can also be retrofitted to existing mills with bronze or white-metal pad-based systems. The Polymer HSB system has self-lubricating properties, which eliminates the need for an emergency lubrication delivery system; simplifying and improving the robustness of the entire mill bearing system.

The polymer HSB system’s state-of-the-art self-aligning capability ensures that the pads are always precisely aligned with the mill journal. This helps to protect the longevity of the mill by distributing stresses more evenly across the support structure and mill body. The self-aligning capability is provided through detailed design of the bearing oil galleries which distributes oil and provides unparalleled flexibility for the bearing alignment to the mill journal. The oil gallery and distribution setup is maintenance-free and requires no adjustment over the lifetime of the mill.

The spherical seat and socket joint allows the upper bearing component to self-rotate and aligns to the journal surface.

The elasticity of the material ensures an adequate oil film is maintained at all times and allows the pad surface to self-adjust to accommodate journal defects and other common causes of failure.