- Helps identify potentially hazardous situations

- Pinpoints potential causes of process disruptions

- Offers 24/7 online monitoring and analysis of KPIs

- Provides an easy-to-use and intuitive system

- Modular structure for different process sections

Supporting your operations, from plant design expertise to equipment, parts and services for every stage of your process.

Are you looking to increase production, reduce risks, lower operating costs and enhance environmental performance? Then you are in the right place.

From the design and supply of products for a greenfield plant, to the addition of a single machine for an existing production line, we are here to help.

Rely on OEM experts because not all parts are created equal. Spare and wear parts built to perform.

Helping you get the most out of your equipment and processes.

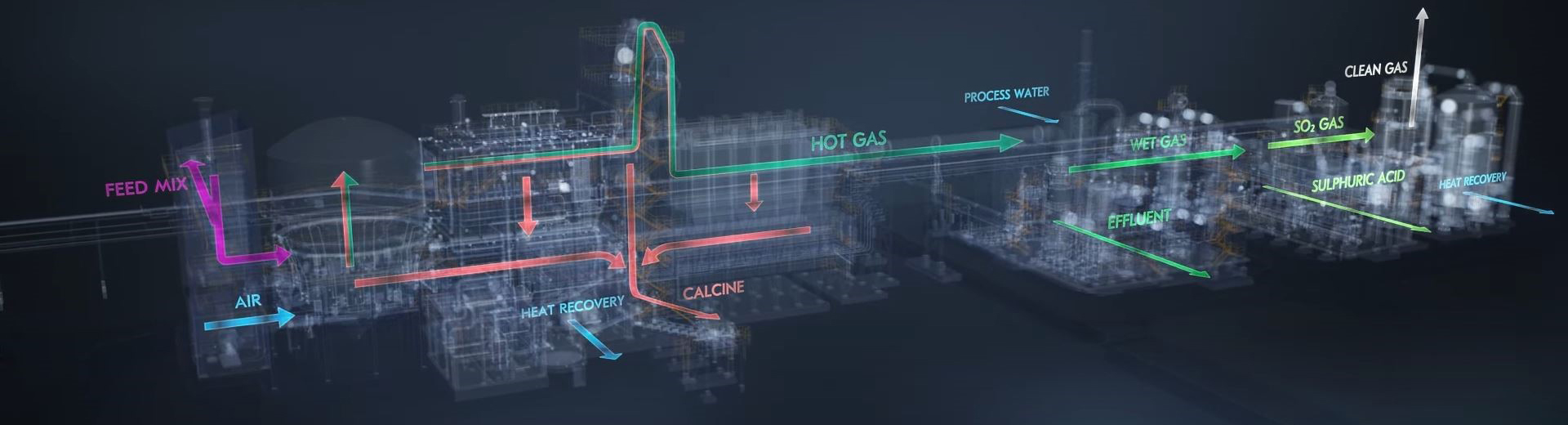

New plants are often designed to operate within very small operational windows or with complex cross linkages between different areas of the chemical facility to allow for optimum energy recovery. Even if a plant is designed without these process constraints, remote locations limit the availability of skilled and experienced operational personnel, and higher workforce turnover leads to less and less truly specialized operators. To help customers overcome this difficult situation, Metso has developed the PORS - system which can guide and support operators in their work and create awareness for potential operational problems.

In most cases, large amounts of data are collected and made available through existing measurements in the plant but not used well enough to stay clear of failures or unplanned shut downs. Through digitalization – bringing value to the digital content by combining it with Metso’s process know-how, we can deliver additional information about the process, plant and individual equipment.

The system is designed to be a standalone solution based on Metso’s proprietary ACT platform which will receive all required process parameters and measurements from the DCS and present the results through its own user interface. The PORS system works in parallel to existing distributed control systems and only requires read access to the DCS. No writing communication to the DCS is necessary.

The PORS expert system will consist of different modules covering the whole process chain with all areas, such as:

Depending on your needs, different combinations of modules can be set up. The modular design allows for quick and easy adaption for existing plants as well as programming of new modules for your specific requirements based on Outotec process know-how.