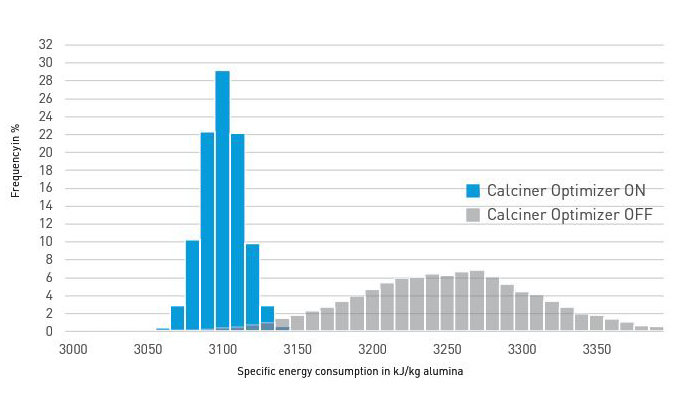

Calciner Optimizer is a digital solution tailored to your specific process challenges. It ensures your plant and equipment operate at peak performance without the need for mechanical adjustments or redesign. You benefit from optimized process operation around the clock, leading to increased annual production and improved profitability.

How it works

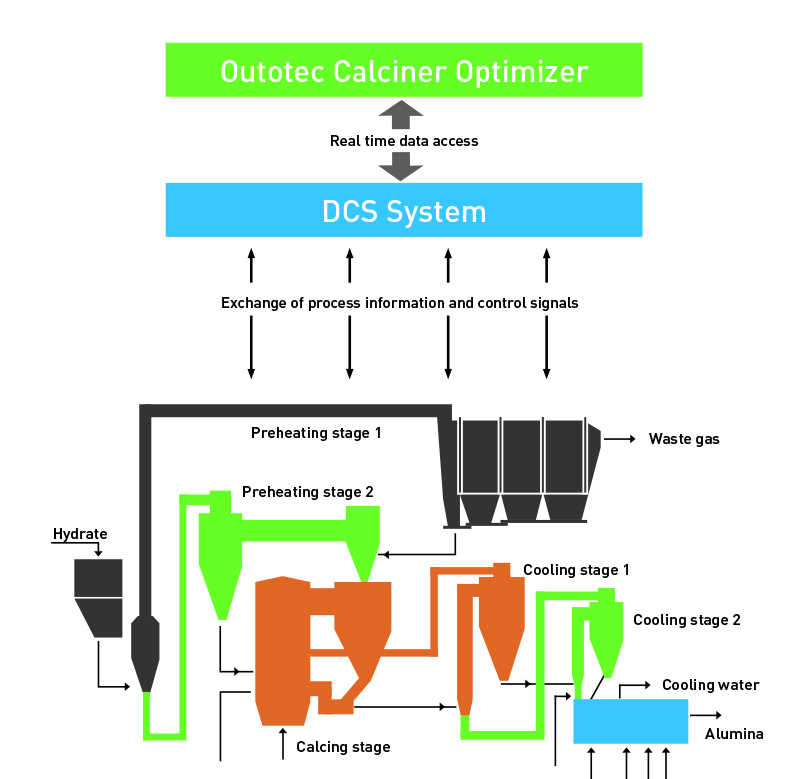

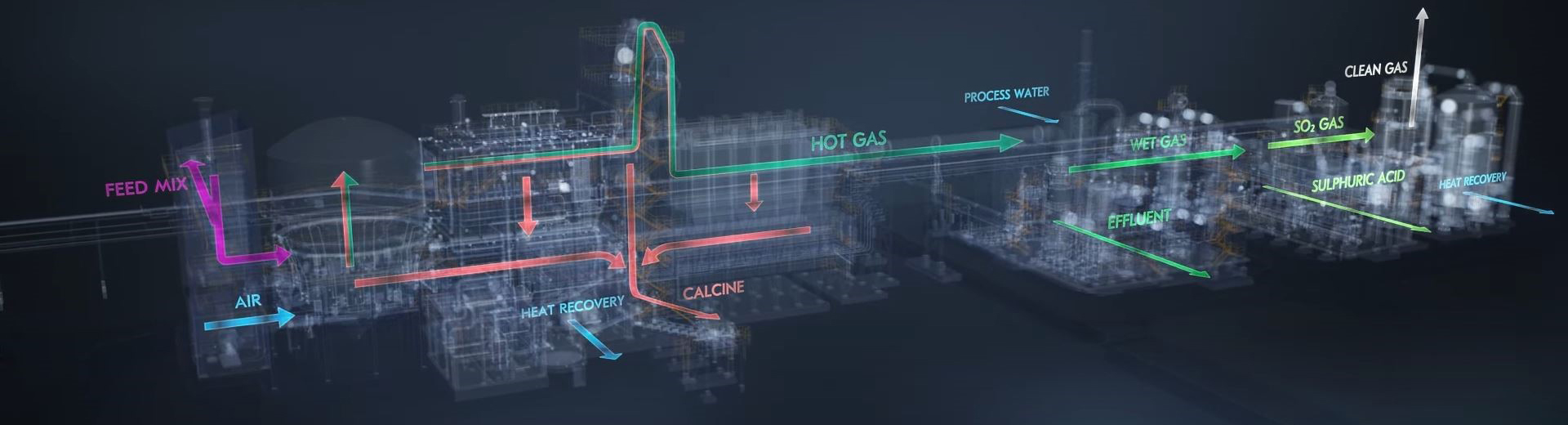

Calciner Optimizer is connected to your plant’s distributed control system (DCS) and monitors all relevant process variables in real time. It uses our process know-how together with heat and mass balances to calculate the optimized process operation modes and set points.

Using detailed models of specific equipment, the system ensures that all parts of the process plant are operating optimally, either by creating targeted advice for operators or by automatically adjusting process parameters.

Compared to traditional manual operation via the DCS, the Calciner Optimizer helps you to operate the plant more efficiently. The tool exchanges information with your plant’s DCS and provides real-time assessment of the process, helping to drastically reduce the workload while increasing operational safety.

Using the operator interface in the control room, operators can quickly and easily adjust high-level process parameters, process limits, and production targets. In contrast to traditional manual operation – where the focus is only on a small subsection of the plant’s available measurements – the Calciner Optimizer system combines many process variables in order to reach conclusions.

Product quality models are adjusted according to your specific plant and operational conditions. Integration of these quality estimation models in the Calciner Optimizer will assist your operators to match production targets.

This digital solution comprises estimations of critical process parameters, such as hydrate moisture. The valuable information it provides to operators enhances their situational awareness and reduces reaction times at critical operational events.