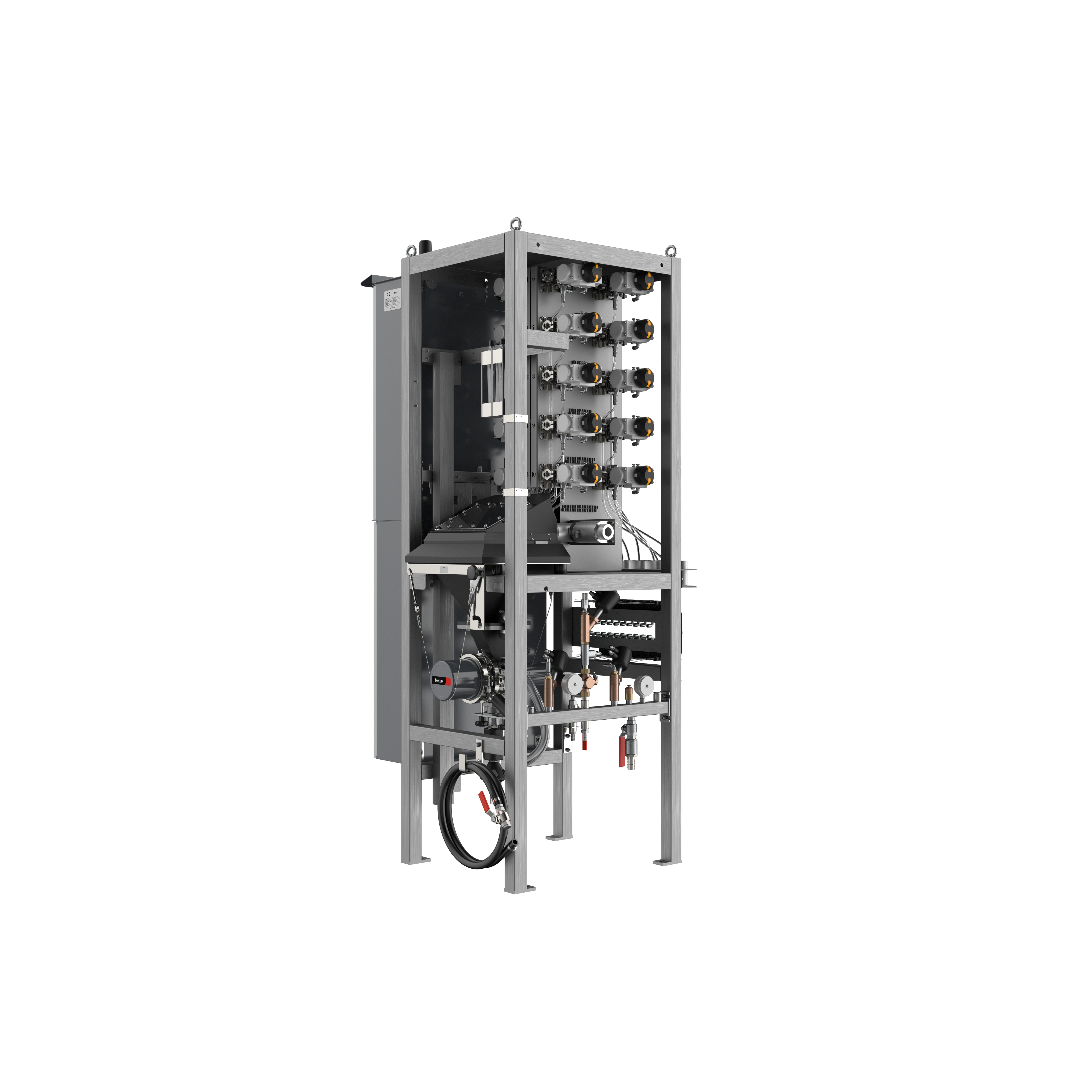

- The PSI 1000 takes samples from up to ten process streams, measuring slurry particle sizes ranging from 0.1 µm to 100 µm.

- Slurry is pumped from a stirred reactor in a fast loop to the analyzer to provide trouble-free transport of the sample.

- The 3-way sample valves of the analyzer turn the slurry flow direction to provide fully representative sample cuts of the slurry streams.

- The system operates continuously 24 hours per day, with minimal manual maintenance needs.

- The particle size analysis is based on laser diffraction.

- Provides reliable reporting and analysis results in real-time for immediate process control.

- Capable of taking samples from one to ten process streams, ensuring comprehensive monitoring.

- Measures slurry particle sizes from 0.1 µm to 100 µm, covering a broad spectrum of particle sizes relevant for industrial applications.

- Operates continuously 24 hours a day with minimal manual maintenance, ensuring uninterrupted process monitoring.

- Air ejector for removal of the diluter unit ammonia vapors.