The natural progression in gear/pinion mill drives

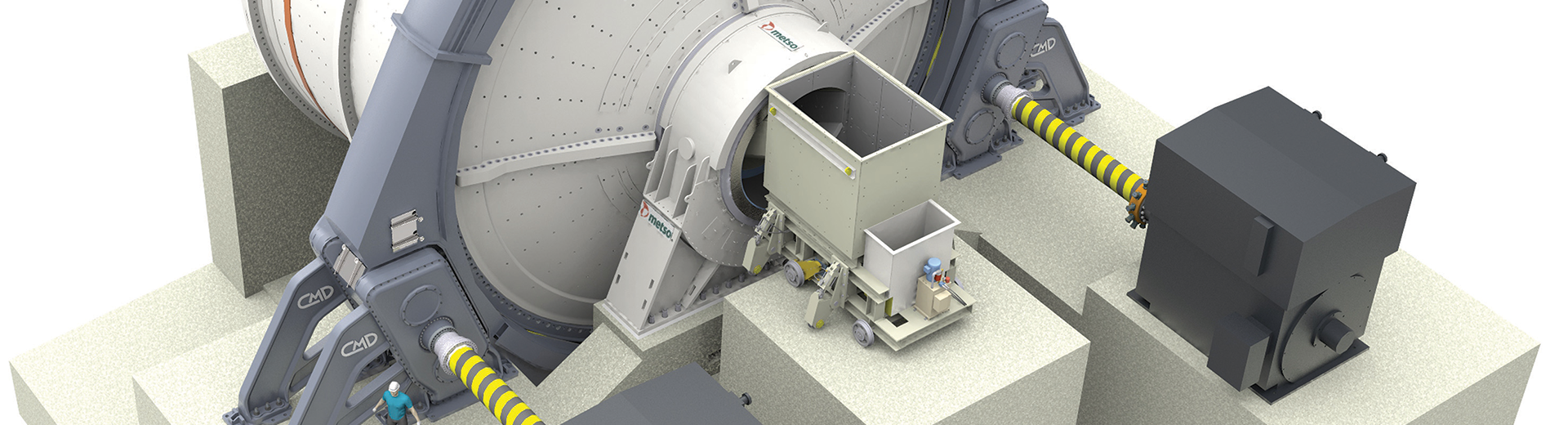

- Foundation design requirements are very similar to dual pinion drive mills

- Significant time savings in installation and commissioning, leading to quicker mill availability

- Reduced equipment mass means a reduction in required shipping and lifting/crane capacities

- Reduction in capital, operating and maintenance spare parts

- Less complexity, simplifies training and specialized services

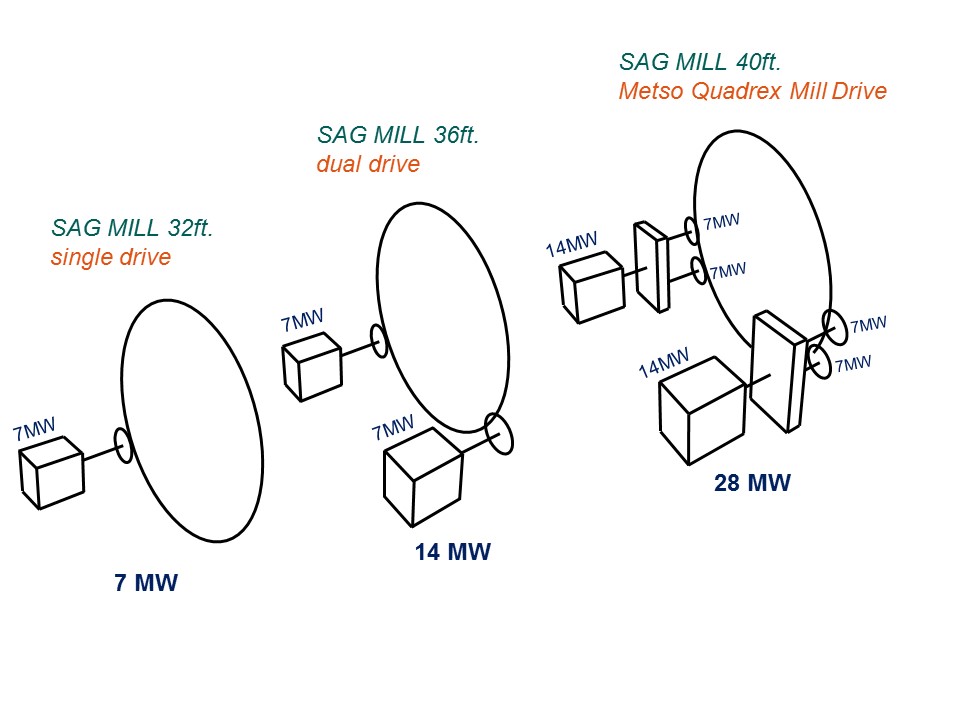

- Standard dual motors comtrolled by variable frequency drive

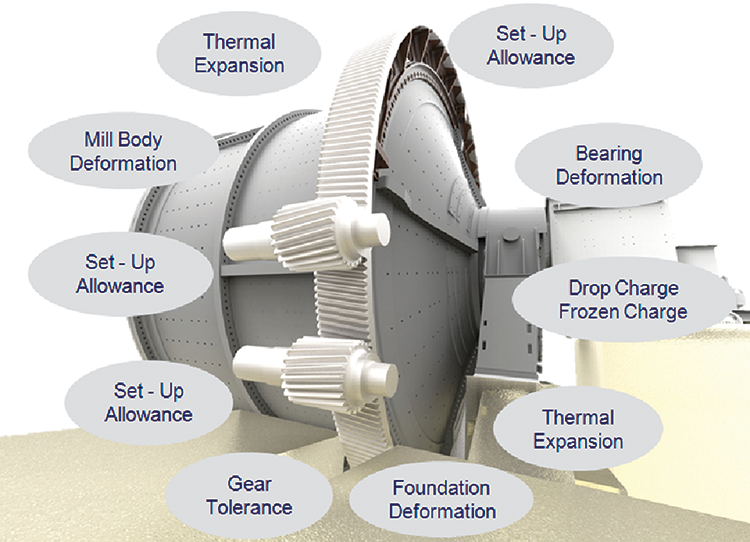

For the Metso QdX4™ Mill Drive system, exhaustive research was conducted to identify all the parameters influencing the entire kinematic mill/drive system. These were evaluated for both the drive and the mill itself throughout the life of the system, so that no single parameter would be ignored. The figure beside depicts many of the parameters considered in the overall design that may have combined direct influence on power sharing.

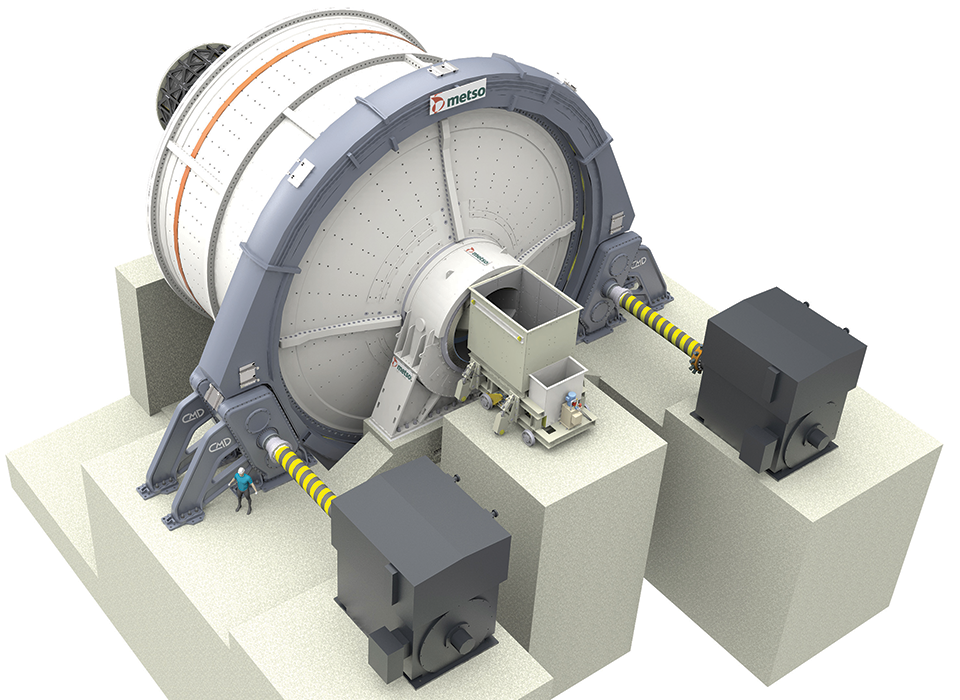

The Metso QdX4™ Mill Drive was developed in close collaboration with both CMD and Ferry Capitain Engineering as a solution for the mining industry for large mill drives. The Metso QdX4™ Mill Drive features internal torque splitting capability transmitting motor input power to the pinion shaft and equally dividing into two mill pinions. This type of torque splitting gear box technology has been in operation since the early 1960’s. We have rearranged the drive architecture in order to apply high powered transmission to large grinding mills in the mining industry.