- Improve productivity and increase metal recovery

- Decrease tailings volumes

- Increase process robustness and improve roaster stability and control

- Extend range of feed materials and increase the recycling of valuable

metals - Increase heat recovery

Supporting your operations, from plant design expertise to equipment, parts and services for every stage of your process.

Are you looking to increase production, reduce risks, lower operating costs and enhance environmental performance? Then you are in the right place.

From the design and supply of products for a greenfield plant, to the addition of a single machine for an existing production line, we are here to help.

Rely on OEM experts because not all parts are created equal. Spare and wear parts built to perform.

Helping you get the most out of your equipment and processes.

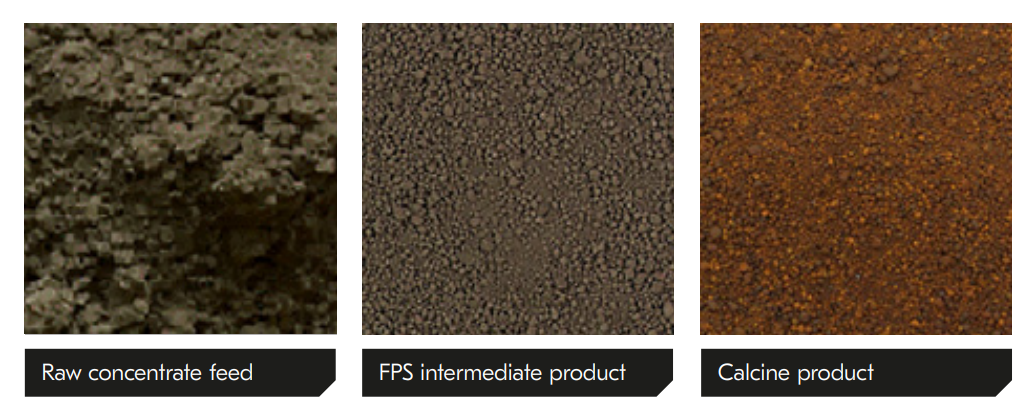

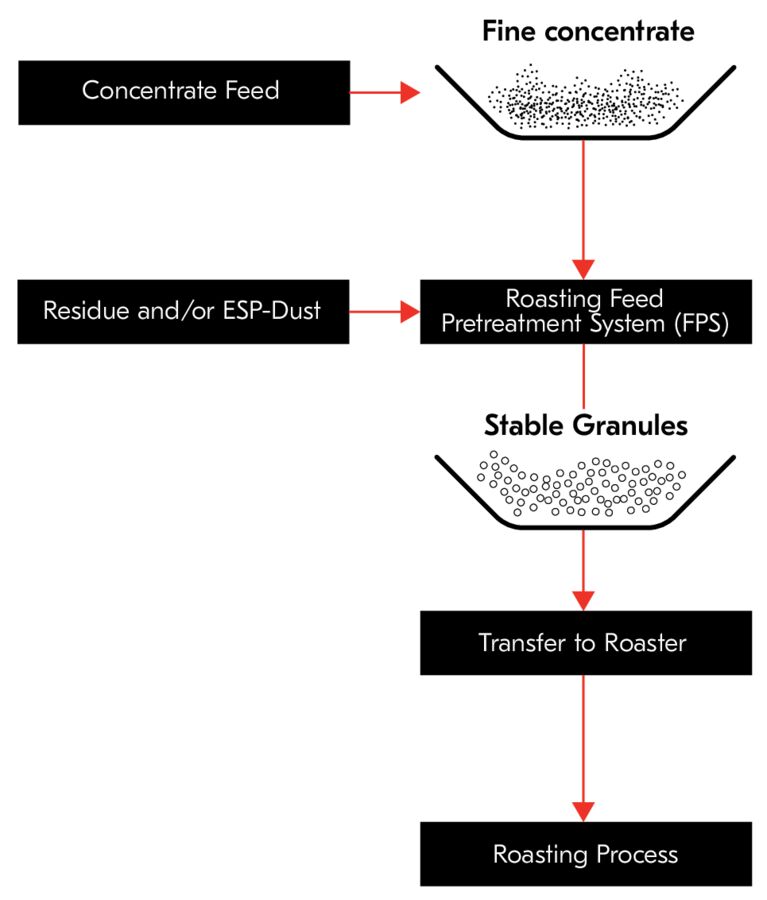

The Metso Feed Pretreatment System (FPS) extends the range of sulphide concentrates and residue materials that can be treated in a roasting plant. Pretreatment becomes a prerequisite as quality resources dwindle and ever more fine particles need to be processed in stable and optimized manner. For traditional and future concentrates, the FPS can assist the roasting plant operators to reach critical operational KPIs such as increased capacity and high product quality. Furthermore, there are the upsides of reduced environmental impact with lower dust emissions and fewer tailings produced. The process enables the recycling of sulphur and/or zinc-containing residues, such as sulphur residue from the Metso direct leaching process, Waelz oxide, or sulphur residue from the Metso Pure Jarosite process. The Metso FPS treats concentrates with or without residue materials and produces stable granules in a distinct particle size that can be effectively processed in fluid bed roasting applications.

In a fluidized bed reactor, fine feed materials are typically entrained partly unreacted with the process gas. Fine feed materials can also combust in the upper section of the furnace instead of in the fluidized bed. This displacement of the combustion causes high temperatures at the top of the furnace, moving process conditions outside of their optimum operation window. The temperature differential between the default roasting temperature in the bed and the furnace top easily reaches more than 100 Kelvin. Most roasters reduce the feed rate to protect the furnace dome against overheating. However, Metso FPS produces stable granules that are more likely to remain in the fluidized bed, whilst ensuring that the granules are roasted to their core. The fine adjustment of different component feed mixtures is carefully analyzed and programmed in specific procedures that maximizes roaster efficiency.

When recycling sulphur cake from hydrometallurgical operations into the roaster, the Metso FPS helps to prevent partial evaporation of the sulphur component in the cake. FPS supports the homogeneous distribution of the sulphur in the feed stream and its controlled combustion inside the roaster.

The system can be integrated into the complex feed area of an existing zinc roaster, using sulphur residue and fine zinc concentrates as feed materials. The system is suitable for a wide variety of fine and ultrafine feed materials like sulphur cake, Waelz oxide, dust, and fine zinc concentrates.

A considerable proportion of global zinc production originates from direct leaching plants. One unavoidable byproduct of these plants is sulphur cake, which is predominantly still directed to industrial landfill. Typical sulphur cake contains 50–70% elemental sulphur and up to 10% sulphidic sulphur along with varying amounts of gangue minerals, metal compounds, and impurities. The Metso FPS can treat those residues and therefore reduce tailings volumes significantly.

Due to its rheological characteristics, sulphur cake requires extensive industrial landfill areas. Attempts to upgrade sulphur cake into a salable product have not been successful to date.

Co-combustion of sulphur cake with zinc concentrate in fluid bed roasting furnaces frequently causes process disturbances in downstream plant equipment and certainly reduces roaster performance. Sulphur cake lumps partially evaporate in the furnace and condense in colder plant sections, forming a sticky residue, particularly in gas cleaning section. The consistent granule sizing from the Metso FPS system helps improve the robustness of downstream processes to increase plant availability.

Metso has confirmed in pilot test work that sulphur residues can be completely combusted in a roasting furnace using its FPS technology. It is essential that the fine-grained material is completely disintegrated and homogenously blended with other feed materials. The Metso FPS ensures optimum homogeneity of feed material from a variety of sources. Fine particles are captured in microgranules of 0.1–0.7 mm in size. This artificial coarsening of fine particles permits the roasting of feed materials that would otherwise be too fine for fluid bed application.

Shifting the reaction zone from the freeboard down to the fluid bed also allows for a higher specific energy density in the bed. This also improves the overall heat recovery in process zones for roaster bed, offgas and calcine product cooling. The heat recovery zones are shifted to more efficient areas, increasing the availability of the off-gas heat recovery system.

We collect and process your data on this site to better understand how it is used. You can give your consent to all or selected purposes or decline the non-essential ones. Essential cookies, which are necessary for the basic website functionality such as page navigation, cannot be declined. Without these cookies, the website would not function properly. For more details, please refer to our Privacy Notice.

Privacy Notice