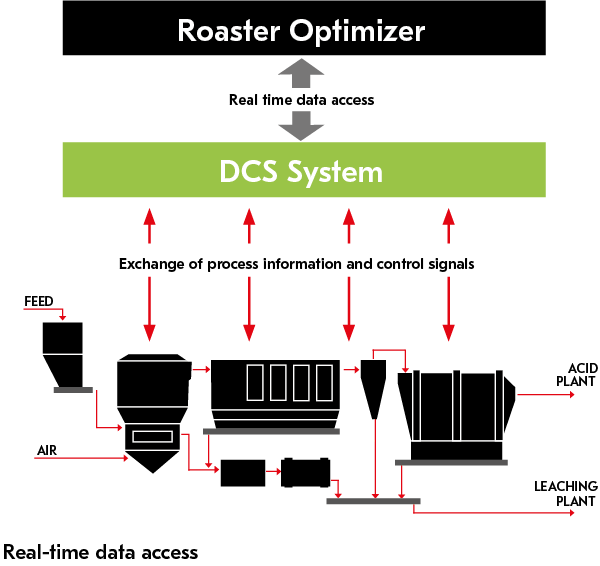

The Roaster Optimizer is our digital solution to your specific process challenges. It helps you achieve optimal operational conditions for your production process and reduce costs by ensuring that the roaster bed and off-gas temperatures are maintained within preset limits. The tool is based on over 50 years of experience in the roasting business and several decades of expertise in sustainable metals and chemicals processing.

The tool keeps track of various process variables and automatically monitors all relevant process parameters, taking into account how they affect each other. By doing so the system identifies the optimal operating conditions for the whole roasting plant and not just for standalone process values. Furthermore, parameters of the downstream process steps that are directly connected to the roaster are taken into account during the process optimization.

An added benefit of having a stabilized and optimized production process is increased plant availability due to reduced process fluctuations, which in turn enables an increase in optimized annual production levels and further increases your plant’s profitability.