Ensures pellets with excellent and consistent metallurgical and physical properties

Optimal plant performance with regard to productivity, energy efficiency, process stability and product quality

Designed by the technology leader, focusing on the entire pelletizing process

Lowest TCO due to longevity and maintainability of the equipment and service support

Importance of green pellet quality and size distribution

Green pellet screening concepts

Single Deck Roller Screens in the green pelletizing area

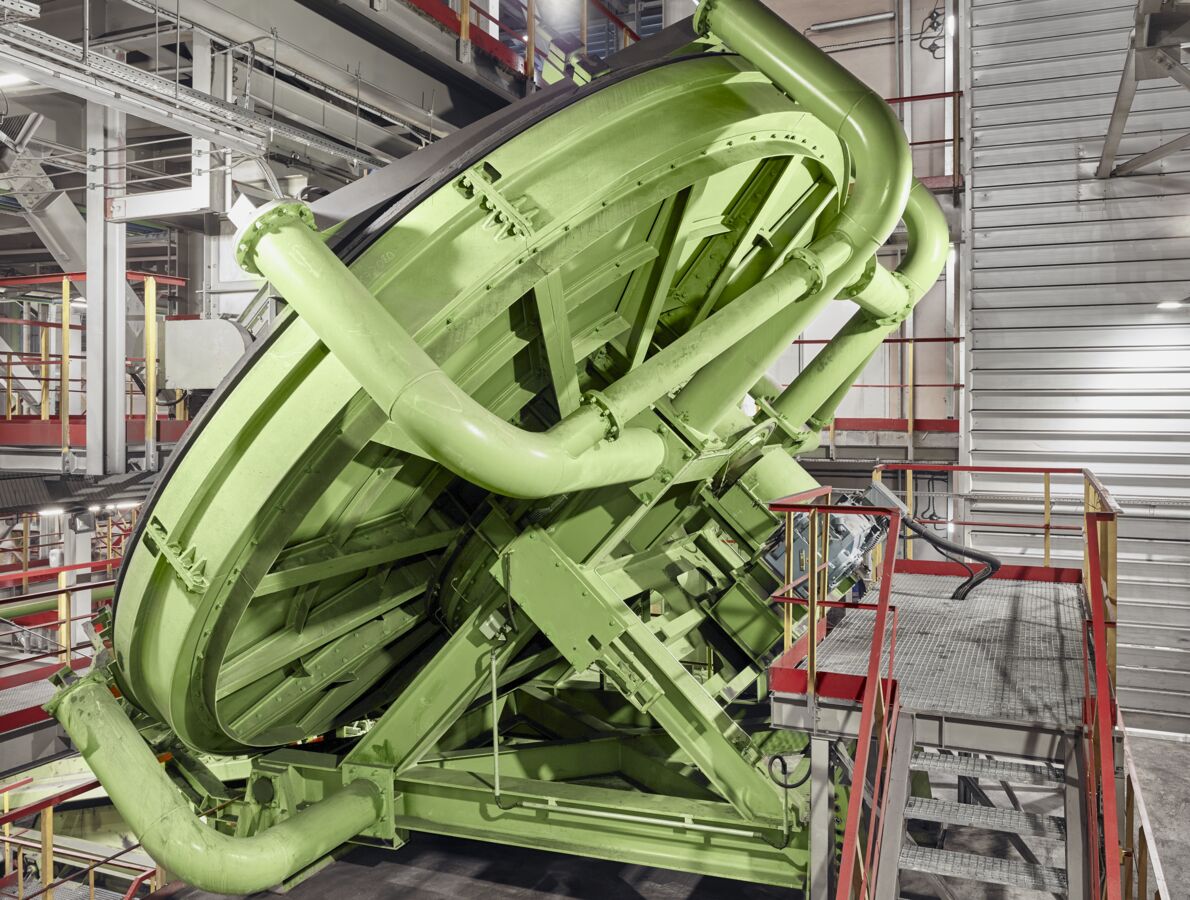

Metso's Single Deck Roller Screens (SDRS) provide a reliable and efficient solution for screening undersize pellets directly after the discharge of pelletizing discs or drums. The screens provide excellent screening efficiency and can be delivered with single roll drive and chain drive, each with its own benefits. Important for the performance of the plant is the arrangement of these screens to:

- reduce overall drop-height through direct charge to the collecting belt

- optimize pellet distribution on the collecting belt with movable screens

Roller screen options in the feed area of the induration furnace

- Single Deck Roller Screens (SDRS)

Economic solution in plants with roller screens in the green pelletizing area. Removes once again under-size pellets and ensures uniform pellet distribution to the furnace.

- Double Deck Roller Feeder (DDRF)

Standard set-up in smaller pellet plants without screening in the green pelletizing section to screen out over- and undersize pellets and feed the pellets evenly to the furnace.

In the recent years plants with bigger capacities and roller screens in the pelletizing section were equipped with DDRF to further improve the pellet size distribution.

- Bi-layer feeders

A relatively new solution is the bi-layer feeders, a advancement of the DDRF with the target to homogenize and improve the pellet quality. It utilizes the bi-layer principle to segregate pellets into two distinct layers in the pellet bed. Larger pellets are charged in the upper section.

Advantages of the bi-layer concept

The bi-layer feeder significantly enhances pellet bed properties in the induration furnace, resulting in better average Cold Crushing Strength (CCS) and Abrasion Index figures. It performs two key functions:

- Size Segregation. Removes fines on the lower deck, ensuring uniformity in the production line.

- Layering. Larger pellets are placed in the upper section, exposed to the firing temperature for a longer time. Smaller pellets, requiring less heat, are placed underneath.

With Metso's VisioPellet system the green pellet size distribution can be further improved. Based on online green pellet size measurement directly under the pelletizing discs or drums the process control system optimizes relevant process parameters like the rotation speed and inclination of pelletizing discs, feed rate, and the addition of additives or water.

The pellet size distribution data can be used to determine a medium pellet diameter and optimize the gapping of the Bi-Layer Feeder, which is even more significant with varying raw material properties such as grain size, moisture, and different ore sources.