Webinar: Turn your rotary kilns green

Join our session on June 29th at 4-5 PM CET

Supporting your operations, from plant design expertise to equipment, parts and services for every stage of your process.

Are you looking to increase production, reduce risks, lower operating costs and enhance environmental performance? Then you are in the right place.

From the design and supply of products for a greenfield plant, to the addition of a single machine for an existing production line, we are here to help.

Rely on OEM experts because not all parts are created equal. Spare and wear parts built to perform.

Helping you get the most out of your equipment and processes.

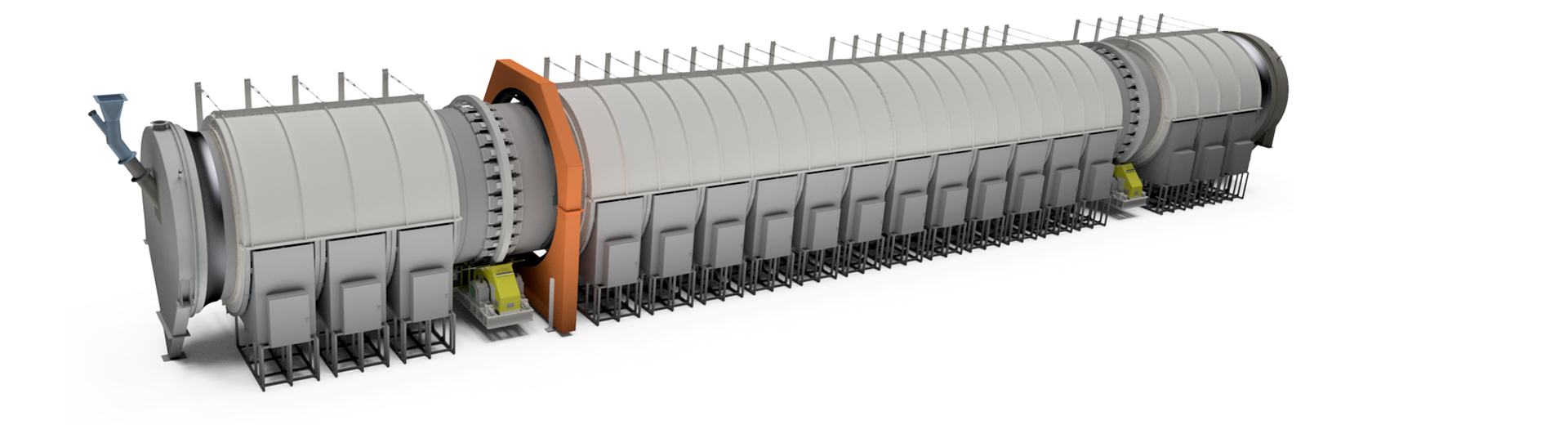

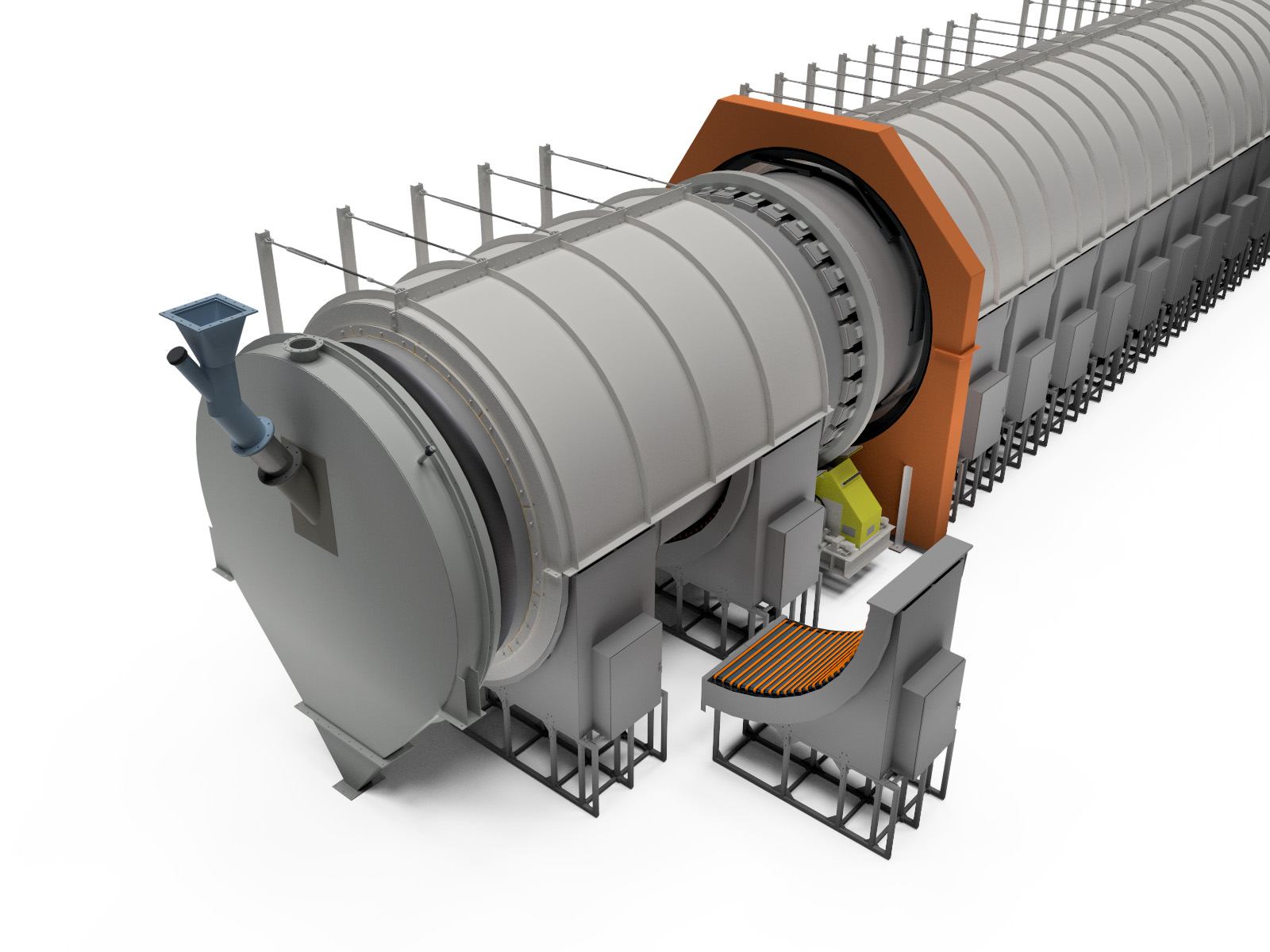

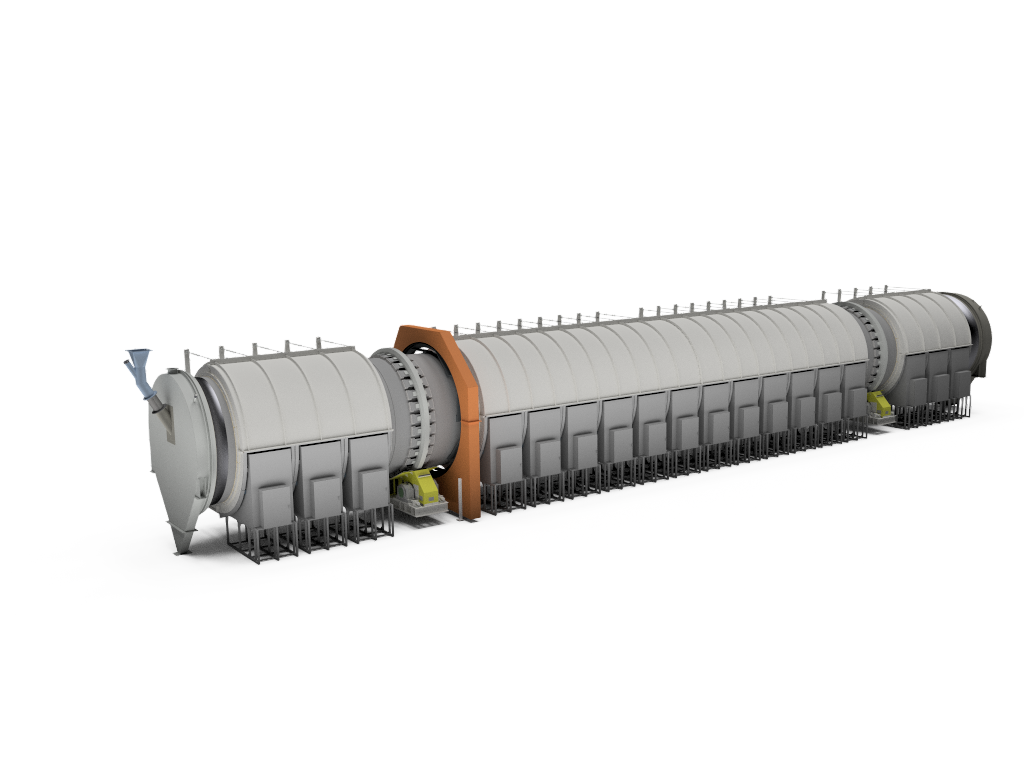

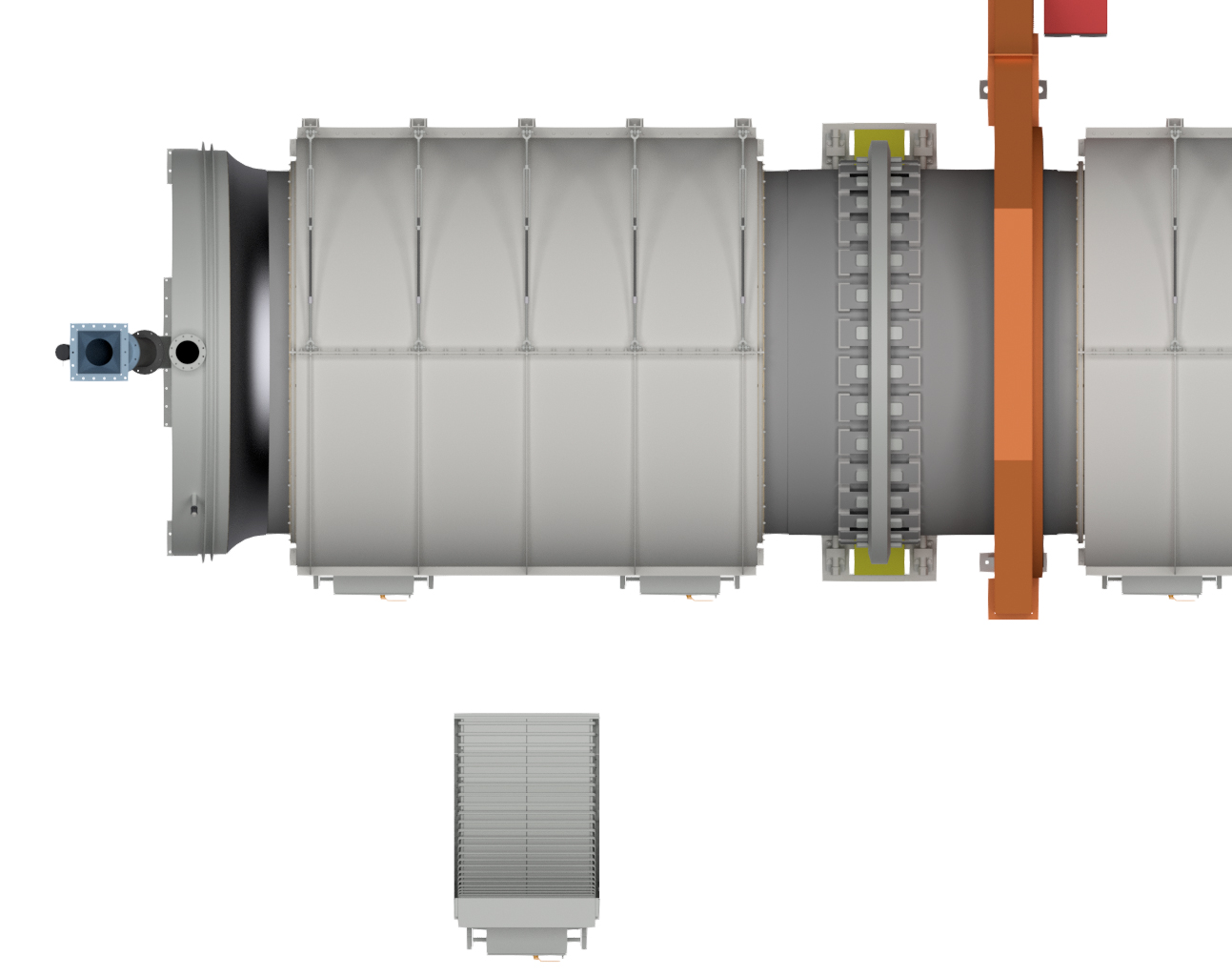

Metso RotarEkiln is an innovative kiln design which uses a more efficient, zero-emission furnace. As the name signifies, RotarEkiln is an electrically powered, indirectly-heated rotary kiln, which doesn’t consume fossil fuels. For the RotarEkiln, the burner system of standard indirect rotary kilns is substituted by an electric heating system, which utilizes resistive emitters that provide radiative heat transfer to the kiln shell. Metso’s RotarEkiln systems can accommodate shell diameters of up to 5 meters – which makes it the only commercially available electric kiln at this scale.

Possible RotarEkiln applications

The global battery metals market, such as for Li-ion battery metals, is identified as one of the essential areas to progress with the decarbonization of industry and society. There is a tremendous rising demand for electric vehicles, energy storage systems and more.

For lithium production, there are several different process routes available or under development. The selection of the process route and main equipment determines not only the initial investment cost, but also the operational cost and the Li yield for the coming decades and ultimately the plant’s future competitiveness.

The RotarEkiln’s modular heating sections can be designed identically to allow interchangeability and common spare parts. Length increments are catered to each application to offer superior temperature control over fuel-fired designs.

Metso RotarEkiln offers:

Hoods at feed and discharge ends of the kiln shell to efficiently control transfer of gases and solids. Special seals between hoods and rotating shell minimize ingress air and maintain required process atmosphere.

Kiln shell is heated externally, therefore selected material must withstand temperature, corrosion, and/or abrasion.

Enshrouding furnace: heating up kiln shell with electric emitters while isolating process gases from environment.

Electric emitters: Resistive heating elements in varying lengths based on voltage supply. The element face temperatures can exceed 1500°C transfer infrared radiation to the kiln shell.

Heating modules with electric emitters, insulation, wiring, and junction boxed for fixed kiln length increments. Easily serviceable, replaceable, and exchangeable.

Heating zones: Modules in series are actuated to maintain a temperature setpoint.

Furnace seals for highest efficiency and protection of elements and personnel.