Versatile applications

Carbon transfer in gold leaching. Handling of large stringy solids. Dandling of long stringy solids.

Design

Heavy-duty pump shaft moves freely under the bearing housing. No journal bearings below the liquid level to maintain.

Robust parts

Hydraulic parts are available from stock in cast iron and stainless steel and high chrome.

Global expertise, local support

Pumping and minerals processing professionals in over 60 countries in the world.

Metso vertical induced flow pumps range is better known as Sala ST Series vertical induced flow pumps.

Equipped with single suction and no shaft sealing, Sala ST vertical pumps can handle severe corrosion, abrasion and temperature extremes in the chemical, minerals processing, pulp and paper, brewing, food and other industries.

Typical applications

- Carbon transfer in gold leaching

- Handling of large stringy solids

The heavy duty pump shaft moves freely under the bearing housing.

There are no journal bearings below the liquid level to maintain. The pump has no stuffing box and thus does not require sealing water.

Metallurgy

Hydraulic parts are available from stock in cast iron and stainless steel and high chrome. Some sizes are also available with rubber lined or polyurethane wear parts.

The pump frame assemblies below the base plate are available in carbon steel and stainless steel. Other materials are available upon request.

Vortex impeller available

This recessed impeller is located out of the flow pattern. The pumping effect is performed by the vortex that the impeller generates in the slurry.

The passage through the vortex pump is fully open, therefore it is especially suited for pumping fibres and similar material.

Impeller adjustment

Easily adjustable shaft allows setting of pump clearances for maximum performance.

V-belt drive

The V-belt drive permits simple cost-effective adjustment of pump flow rate.

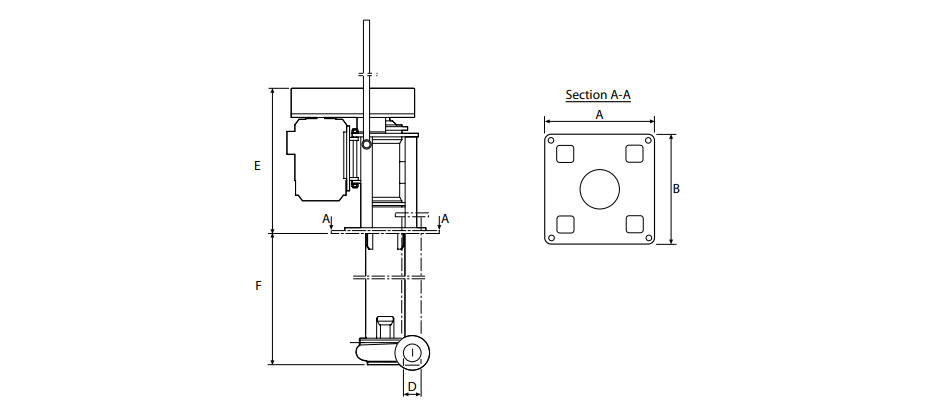

Sala ST vertical induced flow pumps technical specifications

Model | Lower frame | A | B | D | E | F | Motor | Power | Weight |

|---|---|---|---|---|---|---|---|---|---|

| STGVA 22WFR L120 | 120 cm (47") | 600 mm (24" ) | 600 mm (24" ) | 76 mm (3") | 810 mm (32") | 1270 mm (50") | NEMA | 22 kW (30 hp) | 385 kg (850 lbs) |

| STGVA 22WFR L150 | 150 cm (59") | 600 mm (24" ) | 600 mm (24" ) | 76 mm (3") | 810 mm (32") | 1570 mm (62") | NEMA | 22 kW (30 hp) | 410 kg (905 lbs) |

| STGVA 22WFR L180 | 180 cm (71") | 600 mm (24" ) | 600 mm (24" ) | 76 mm (3") | 810 mm (32") | 1870 mm (74") | NEMA | 22 kW (30 hp) | 435 kg (960 lbs) |

| STGVA 33WFR L120 | 120 cm (47") | 600 mm (24" ) | 600 mm (24" ) | 76 mm (3") | 810 mm (32") | 1300 mm (51") | NEMA | 22 kW (30 hp) | 395 kg (870 lbs) |

| STGVA 33WFR L150 | 150 cm (59") | 600 mm (24" ) | 600 mm (24" ) | 76 mm (3") | 810 mm (32") | 1600 mm (63") | NEMA | 22 kW (30 hp) | 420 kg (925 lbs) |

| STGVA 33WFR L180 | 180 cm (71") | 600 mm (24" ) | 600 mm (24" ) | 76 mm (3") | 810 mm (32") | 1900 mm (75") | NEMA | 22 kW (30 hp) | 445 kg (980 lbs) |

| STGVA 44WFR L120 | 120 cm (47") | 600 mm (24" ) | 600 mm (24" ) | 76 mm (3") | 810 mm (32") | 1330 mm (52") | NEMA | 22 kW (30 hp) | 405 kg (890 lbs) |

| STGVA 44WFR L150 | 150 cm (59") | 600 mm (24" ) | 600 mm (24" ) | 76 mm (3") | 810 mm (32") | 1630 mm (64") | NEMA | 22 kW (30 hp) | 430 kg (945 lbs) |

| STGVA 44WFR L180 | 180 cm (71") | 600 mm (24" ) | 600 mm (24" ) | 76 mm (3") | 810 mm (32") | 1930 mm (76") | NEMA | 22 kW (30 hp) | 455 kg (1000 lbs) |