Layout flexibility

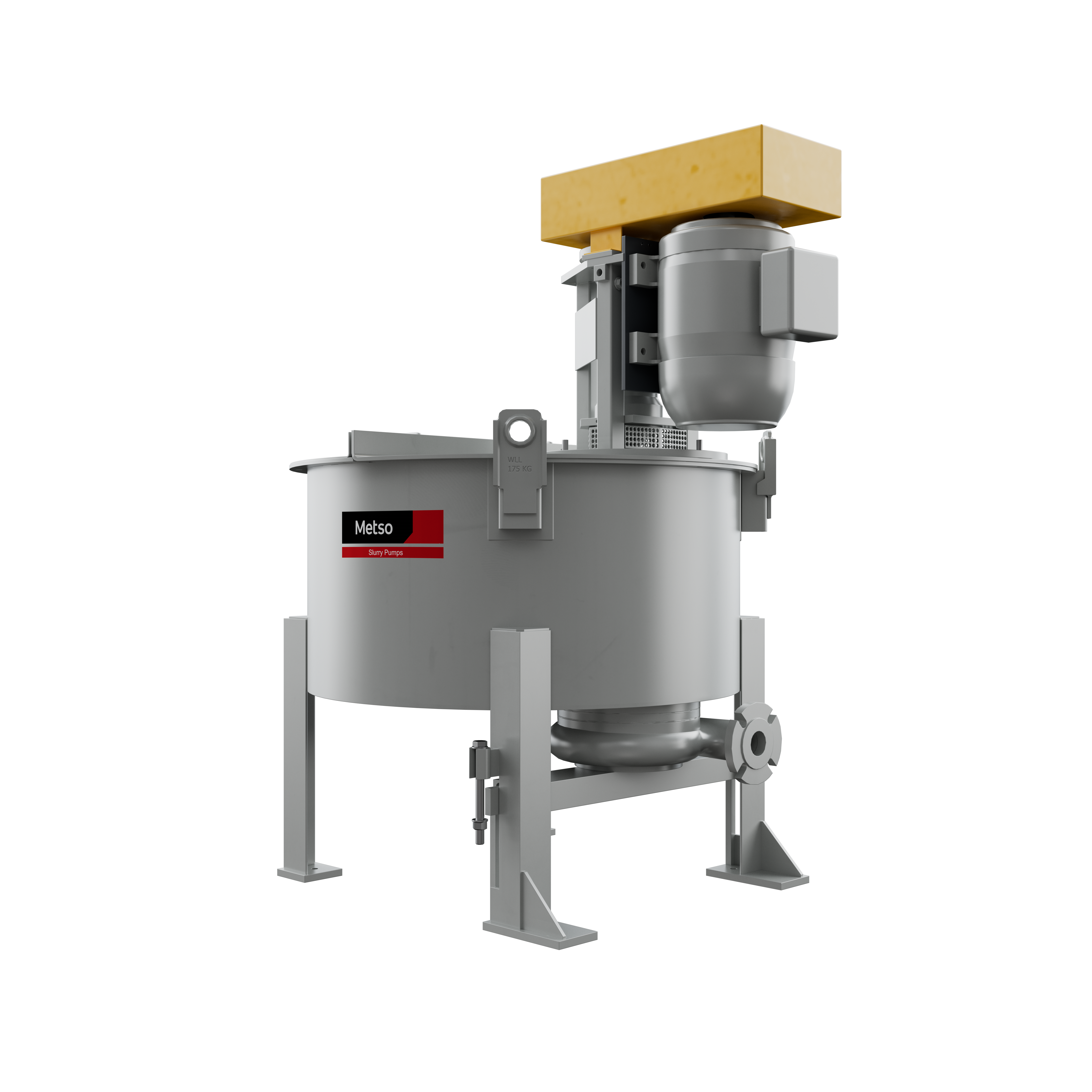

The pump, pump sump and motor are integrated in one self-contained unit.

Smooth operation

The open tank design with a vertical “wet end” inlet prevents air blocking by allowing entrained air to run up the shaft.

Cantilever design

The heavy duty pump shaft is a cantilever design, hanging below the bearing housing.

Bearing assembly

The pump shaft is carried in grease lubricated anti-friction bearings.

Metso range of vertical tank pumps is called Sala VT vertical tank pumps. They are available as either rubber lined or hard metal lined versions.

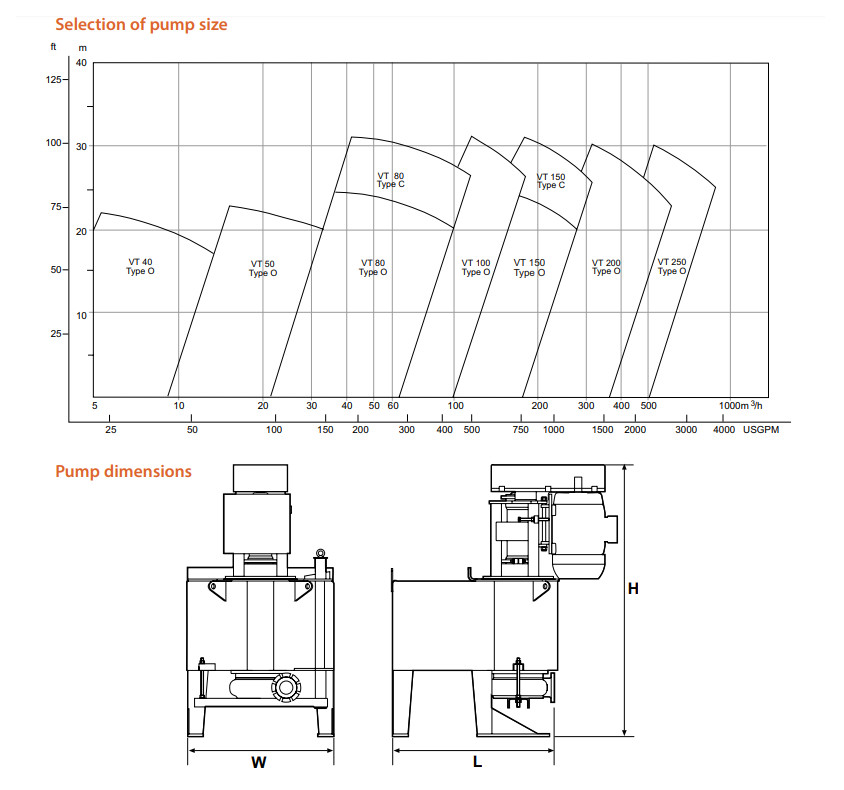

- Flow rates to 700 m³/h – 3 100 USGPM

- Heads up to 30 m – 100 ft

Typical applications

- Feed to dewatering cyclones in sand plants

- Screen underflow duties

- Sampling pumps in concentrators

- Permanent, mobile or semi-mobile installations in industrial applications

- Mixing/distribution units in applications for flocculent or lime in sewage plants or cement grouting in tunnels or mines

Layout flexibility

The pump, pump sump and motor are integrated in one selfcontained unit. Simple to install and connect. No alignment or special foundations needed.

Smooth operation

The open tank design with a vertical “wet end” inlet prevents air blocking by allowing entrained air to run up the shaft. These pumps can run dry.

Cantilever design

The heavy duty pump shaft is a cantilever design, hanging below the bearing housing. There are no submerged bearings, stuffing box or shaft seals.

Bearing assembly

The pump shaft is carried in grease lubricated anti-friction bearings. Impeller clearance is maintained by external axial adjustment of the shaft/bearing assembly. Bearings have double protection against ingress of slurry.

Pumps are supplied with a V-belt drive, motor and drive guard. The motor is mounted vertically, with shaft up, on an adjustable motor plate fitted above the tank top, along side the bearing housing.

Motor size and V-belt drive vary with the pump application. Minimum data required for an approximate pump, speed and drive motor selection:

• Slurry flow rate

• Slurry density

• Total discharge head

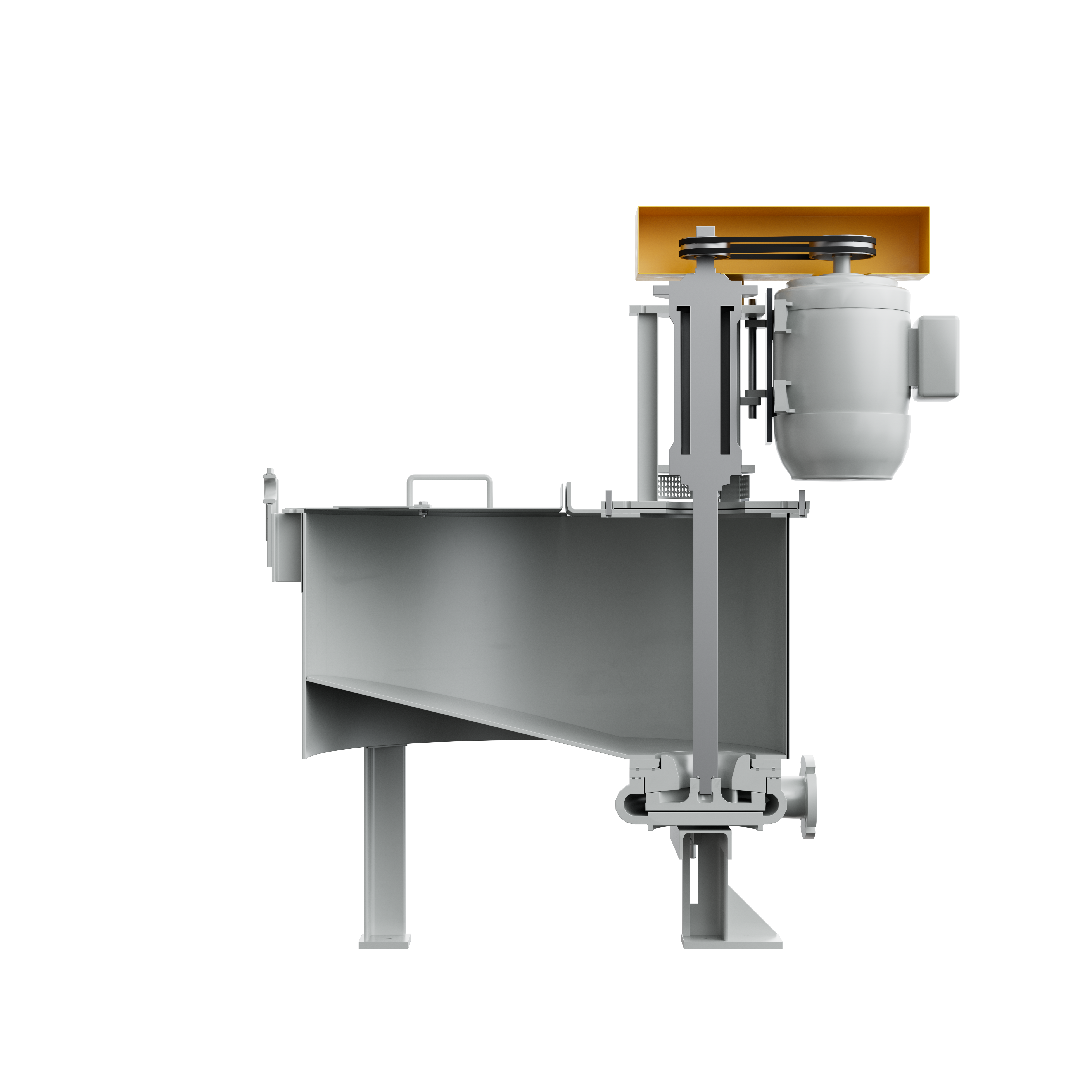

Simplified maintenance

The casing on the VT tank pump is supported by a beam. The beam is either lowered by hand or a hydraulic jack, depending on the pump size.

On larger pump sizes (VT 100 and upwards) the beam can be swung out so that the “wet end” parts can be accessed by a lifting device.

The wear parts have large material sections for extra long wear life and are designed for the toughest applications

Standard pumps are supplied with “wet end” parts in wear resistant Natural Rubber or Wear Resistant High Chrome Iron alloy, with a nominal hardness of 600 BHN.

Other wear part materials available include the Metso range of Natural rubbers, Synthetic rubbers and Polyurethane.

Parts in different materials are fully interchangeable and can be combined for optimum life.

Two different impeller configurations are available for optimum performance:

- Semi open impeller Type O for smooth and blockage free operation.

- Closed impeller Type C which features high head and efficiency.

Sala VT vertical tank pumps technical specifications

Model | Pump discharge | Height | Length | Width | Weight* | Sump volume |

|---|---|---|---|---|---|---|

| VT40 | 40 mm (1.5") | 1 030 mm (40.5") | 740 mm (29") | 610 mm (24") | 110 kg (243 lbs) | 0,06 m3 (16 USG) |

| VT50 | 50 mm (2") | 1 470 mm (58") | 1 035 mm (41") | 1 010 mm (40") | 305 kg (672 lbs) | 0,25 m3 (66 USG) |

| VT80 | 80 mm (3") | 1 880 mm (74") | 1 015 mm (40") | 1 060 mm (42") | 580 kg (1 279 lbs) | 0,33 m3 (87 USG) |

| VT100 | 100 mm (4") | 2 050 mm (81") | 1 225 mm (48") | 1 100 mm (43") | 825 kg (1 819 lbs) | 0,57 m3 (150 USG) |

| VT150 | 150 mm (6") | 2 160 mm (85") | 1 285 mm (50.5") | 1 100 mm (43") | 925 kg (2 039 lbs) | 0,57 m3 (150 USG) |

| VT200 | 200 mm (8") | 3 105 mm (122") | 1 710 mm (67") | 1 510 mm (59") | 2 655 kg (5 853 lbs) | 1,26 m3 (333 USG) |

| VT250 | 250 mm (10") | 3 105 mm (122") | 1 760 mm (69") | 1 510 mm (59") | 2 785 kg (6 140 lbs) | 1,26 m3 (333 USG) |

| *Weight with metal parts. Rubber parts reduce weight by 10% |