Webinar: Risk Planning and Dealing with Unforeseen Challenges During Shutdown Events

Appreciate good planning, understand risk identification and mitigation as well as best practices

With a site-specific safety management plan

With a detailed scope and improved utilization of resources

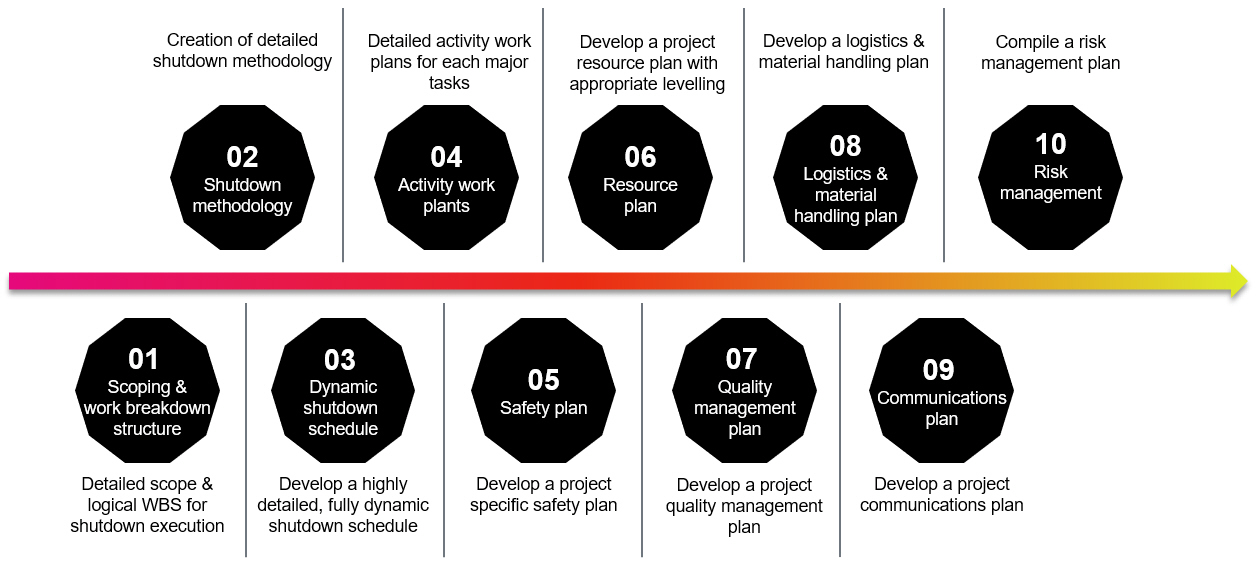

Our 10-point planning system helps you execute shutdowns more efficiently with shorter turnarounds

We are the market leader in roasting plants and metallurgical furnaces, performing plant assessments, shutdown planning, and demolition work for the past 40 years with references from hundreds of projects.

We have a large network of experts to assess your plant performance for best asset utilization prior to shutdown planning and use special robotic demolition machines operated remotely to execute projects on time and budget, putting safety first.

Our pioneering, state-of-the-art roaster remote demolition concept enables a fast and safe shutdown service using our proprietary roasting demolition platform.

Read more here.

Metso demolition methods rely not only on commercially available demolition machines, but also on our special line of Auburn™ machines, tools, and methods that have been designed, developed, and refined over 35 years of demolition projects.

Our priority is safety. We use advanced safety gear and methods to protect our people and your property. Our demolition experts are famous for their ability to remove furnace hearths and bottoms faster than anybody in the business. Our experienced machine operators can rapidly descale and remove refractory material without causing damage to the steel shell. We have experience with various furnace types and metals.