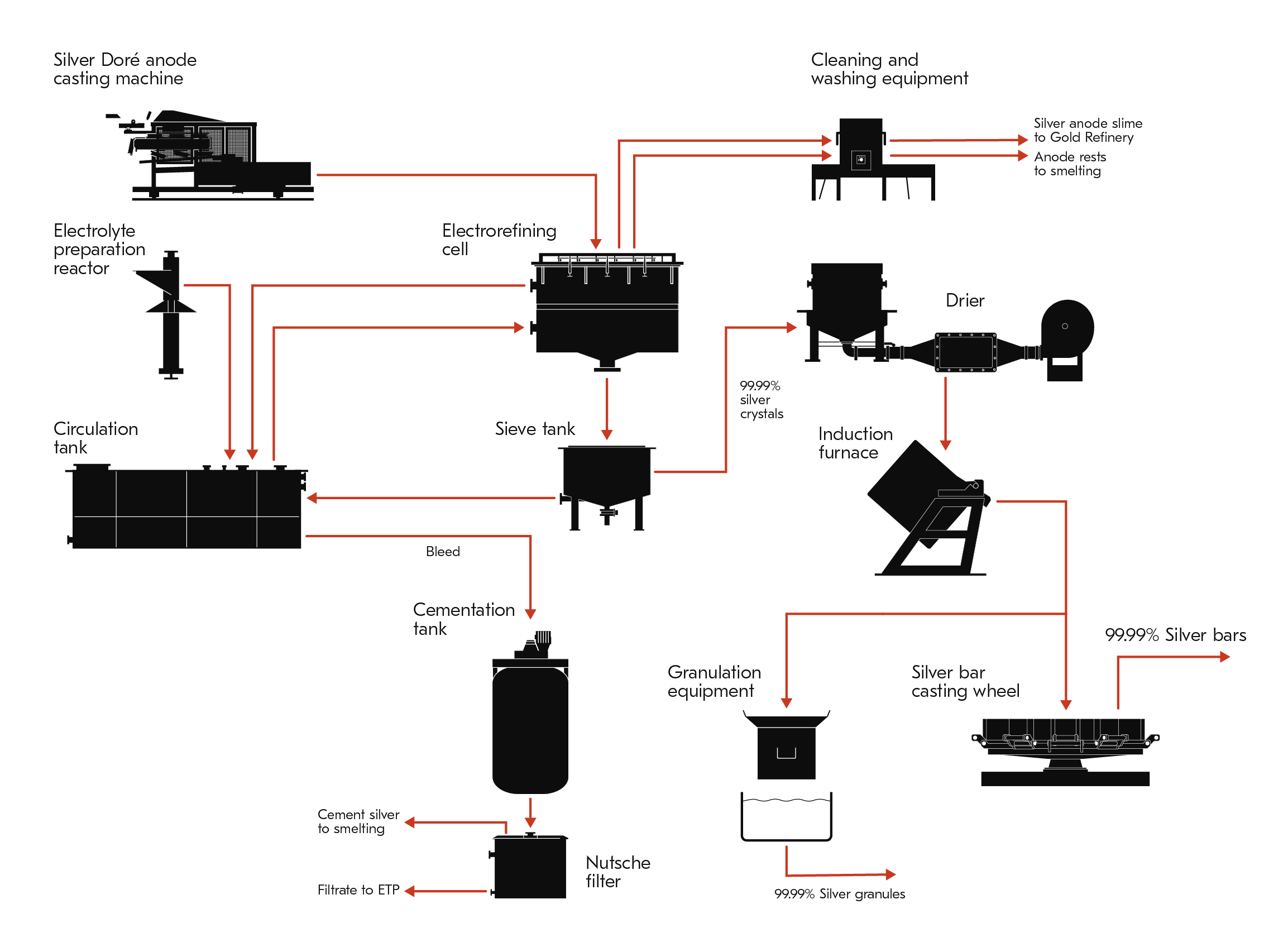

All this helps increase the efficiency of the process, decrease manual work, and increase the amount of silver recovered. The modular design makes it easy to scale the solution for your desired capacity.

Silver anode slime containing valuable impurities such as gold and platinum-group metals (PGMs) is also formed during the electrolysis process. The slime is collected inside anode bags surrounding silver Doré anodes and can be further processed using Metso's Outotec process for Gold Refinery for recovery of gold and PGMs.

The non-dissolved anodes remaining after electrolysis are recycled for smelting and casting of new silver Doré anodes. Spent electrolyte withdrawn from circulation is replaced with fresh silver nitrate electrolyte in order to keep the silver content at a constant level.

Silver Doré anode casting

We offer various solutions for silver Doré anode casting. Our portfolio includes six different designs of both casting wheels and machines for the casting of anodes of variable weights and shapes.

Metso silver electrolysis tankhouse

The heart of Metso's Outotec process for Silver Refinery is the silver electrolysis tankhouse, which consists of electrorefining cells, circulation tanks and pumps, sieve tanks, a cooling system, and a pH control and adjustment system. A sophisticated control system monitors and controls the process, making it both easy to operate and highly efficient. With Metso HCD (High Current Density) silver electrorefining cells, current densities exceeding 1000 A/m2 are possible, depending on the composition of the silver Doré anodes being processed.

The electrorefining process is continuous except when new silver Doré anodes are loaded in the cells and silver anode slime and anode scrap is discharged from the cells at the end of the electrolysis cycle.

The anodes continuously dissolve, depositing refined silver on the cathodes. The cell is equipped with an automatic scraper system that removes the deposits – the silver crystals scraped off the cathodes are collected at the bottom of the cells. At the end of the electrolysis cycle, a slurry containing crystals of cathode silver and electrolyte is discharged into a sieve tank. The quality of the silver crystals produced in the electrolytic refining process is ensured by electrolyte circulation.

Metso silver electrolyte preparation system

Some of the silver crystals produced in the silver electrorefining cell are processed in the Metso silver electrolyte preparation system, where they are dissolved to produce pure silver nitrate solution. The process and equipment design avoids the formation of toxic NOx gases, which improves the safety of the working environment. The system is also available as standalone equipment with its own control system.

Drying of silver crystals

The final product can be either silver bars or silver granules. In both cases the silver crystals are dried using the fully automated Metso Silver Drier, which consists of a fan, a heater, and a sieve tank for the silver crystals. The dried silver crystals are then melted using an induction furnace.

Casting and bar processing

Casting of silver bars is performed using an Metso Silver Bar Casting Wheel for 1000 troy ounce (approximately 31 kg) ingots. The bars are then cooled in a water bath.

Further operations, such as polishing, weighing, marking, and stacking can be performed by the Metso Silver PWMS Robot. The equipment produces silver bars that meet the requirements of the London Bullion Market Association’s Good Delivery standards.

Granulation and packing

Metso Silver Granulation Equipment consists of an induction furnace, granulation equipment and a receiving tank. Granules are dried in the Metso Silver Dryer and packed using a material-handling system that produces ready-to-ship bags that are sealed and marked.