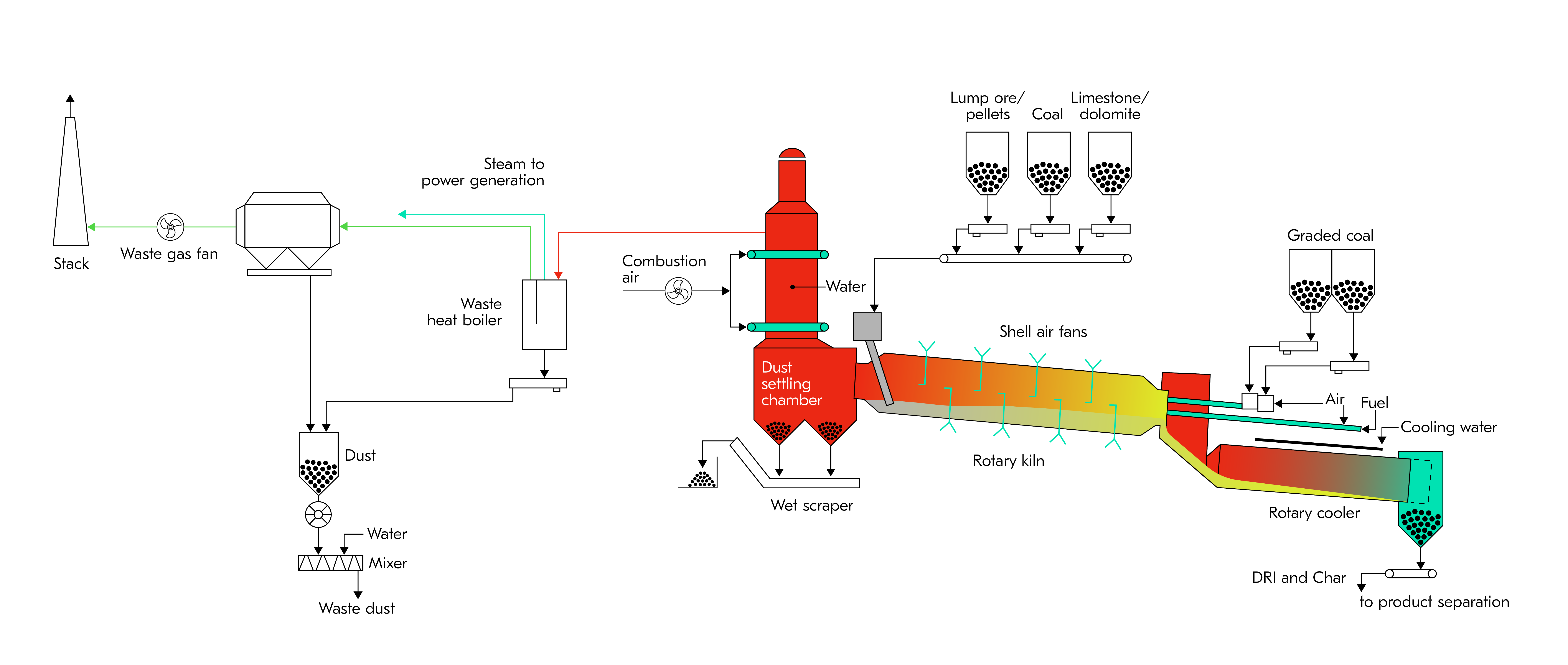

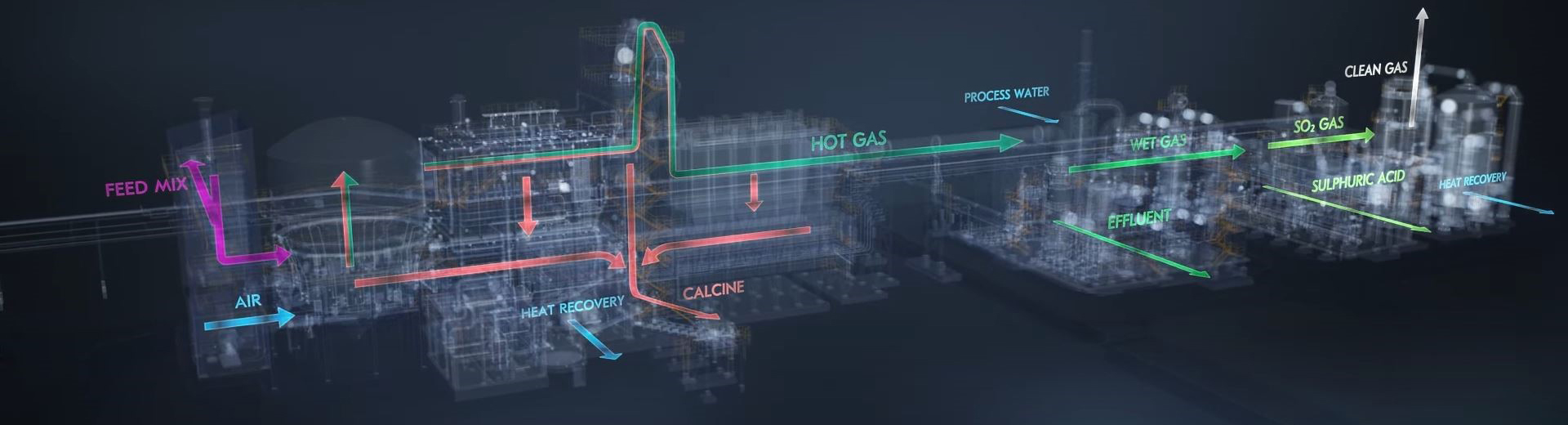

In the standard SL/RN process, iron ore, coal, and dolomite or limestone as desulfurizing agent are charged into a rotary kiln and heated up by a countercurrent gas flow. Heat is generated by the controlled combustion of volatiles from the coal and surplus CO from the charge. The reduction of iron oxides in the solid state is achieved at temperatures between 920°C and 1100°C.

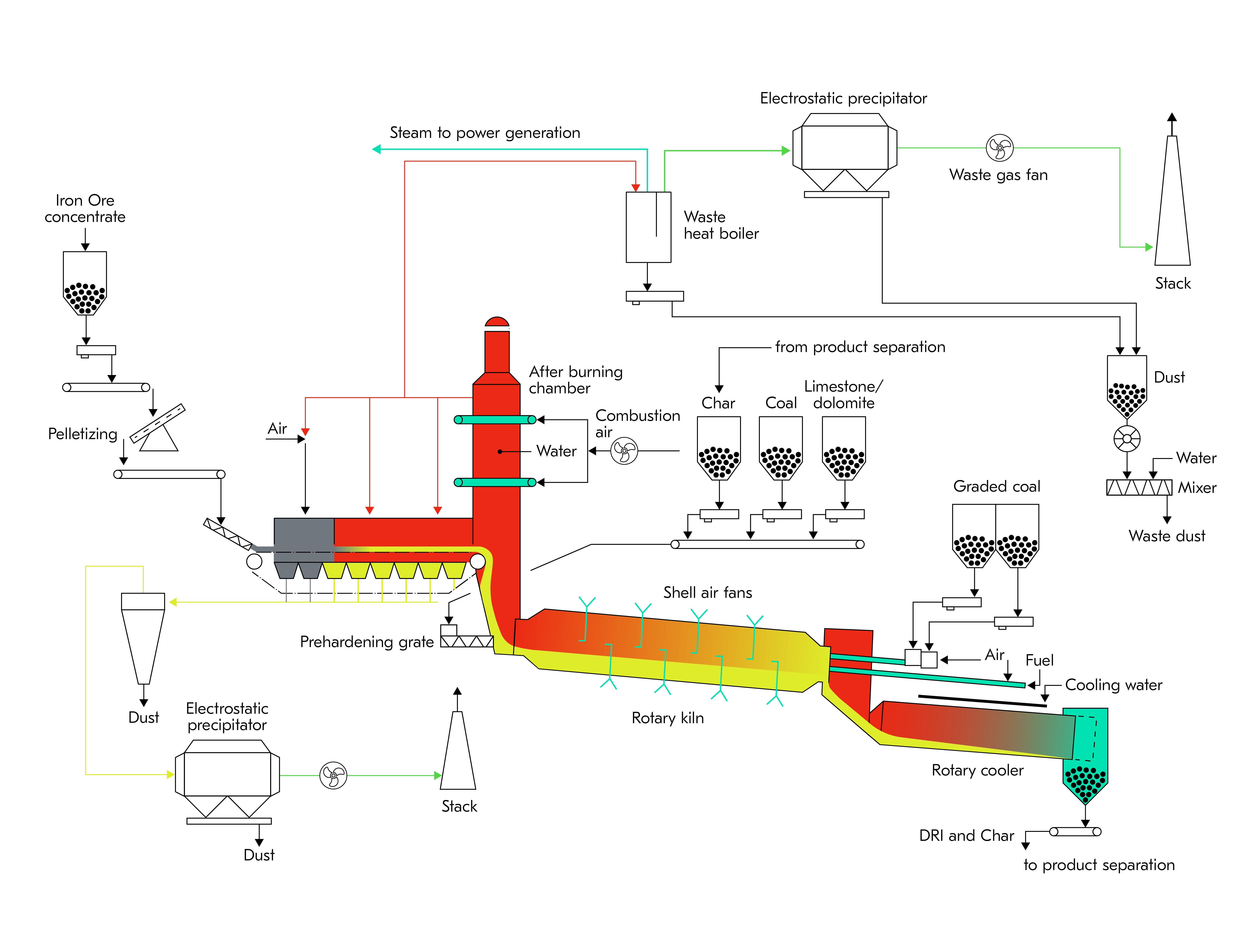

As an answer to decreasing ore grades, availability of lump ore and ever-increasing amount of fine ores and concentrates, Metso has developed a variant of the process, the SL/RN-Xtra direct reduction process, which allows customers to produce direct reduced iron (DRI) for steelmaking directly from concentrates in a single plant, combining pelletizing and direct reduction.

Reduction and coal gasification reactions take place simultaneously within the charge, creating surplus CO leaving the charge. The produced DRI and the residual non-magnetic fraction are magnetically separated after cooling. The waste gas passes through a waste heat boiler to recover heat for steam and subsequent power generation.

Iron ore fines resulting from the concentration process are frequently available at high levels of quality (high iron and low gangue contents) and are therefore most suitable for high-quality DRI production.

Both standard SL/RN and SL/RN-Xtra plants use the following main equipment:

- Raw material handling facilities

- Rotary kiln

- Rotary cooler

- After burning chamber (ABC)

- Waste heat boiler

- Electrostatic precipitator

- Product separation and handling facilities

SL/RN-Xtra also includes:

- Pelletizing facilities

- Pre-hardening grate