Grinding process optimization and connected services

Explore our tools to aid in optimizing your circuit to increase throughput, availability, or reduce energy consumption.

The system provides the opportunity to implement advanced condition monitoring strategies, including remote expert support, to ensure maximum mill availability.

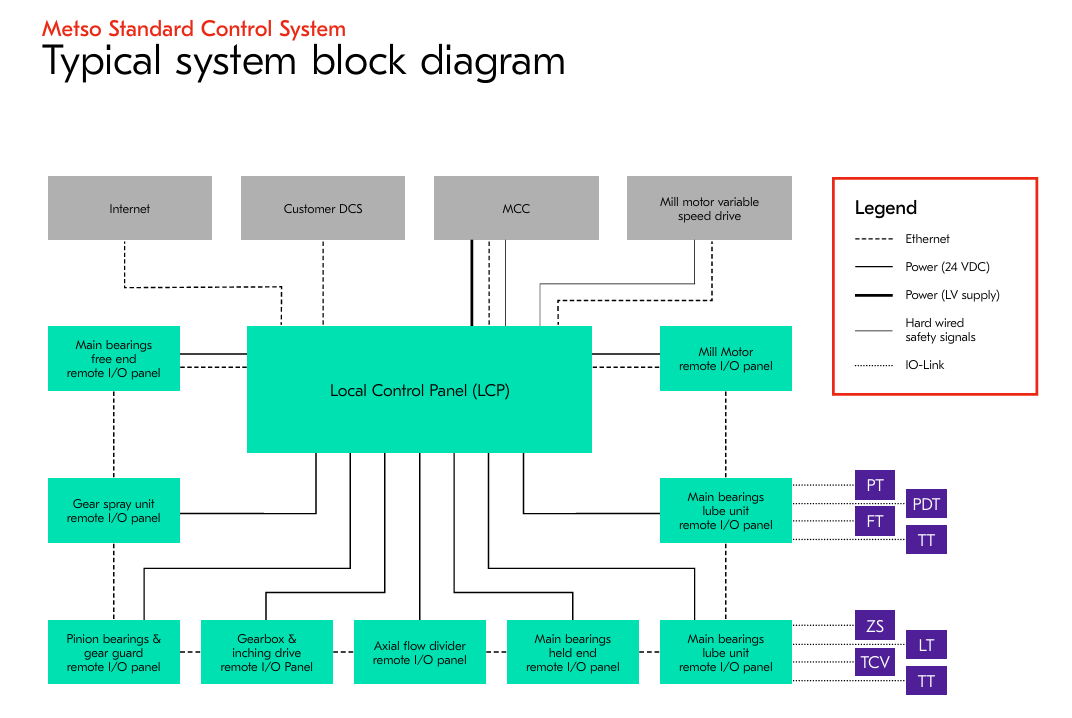

| 1 | Four standardized and configured-to-order local control panel (LCP) products to suit market area and installation requirements: |

| |

| |

| 2 | Remote connectivity hardware and software pre-configured for Metso's cloud-based Connected Services and Asset Analytics |

| 3 | Standard interface protocols and safety signals to plant control system, main drive/starter, upstream switchgear, and motor control center |

| 4 | Robust IP67-rated I/O modules with IO-Link masters (factory installed, wired to instruments, and tested on all skid-mounted components); specially designed stainless-steel brackets included for module mounting and protection |

| 5 | Standardized smart mill instruments that use IO-Link communication and meet the required product certifications |

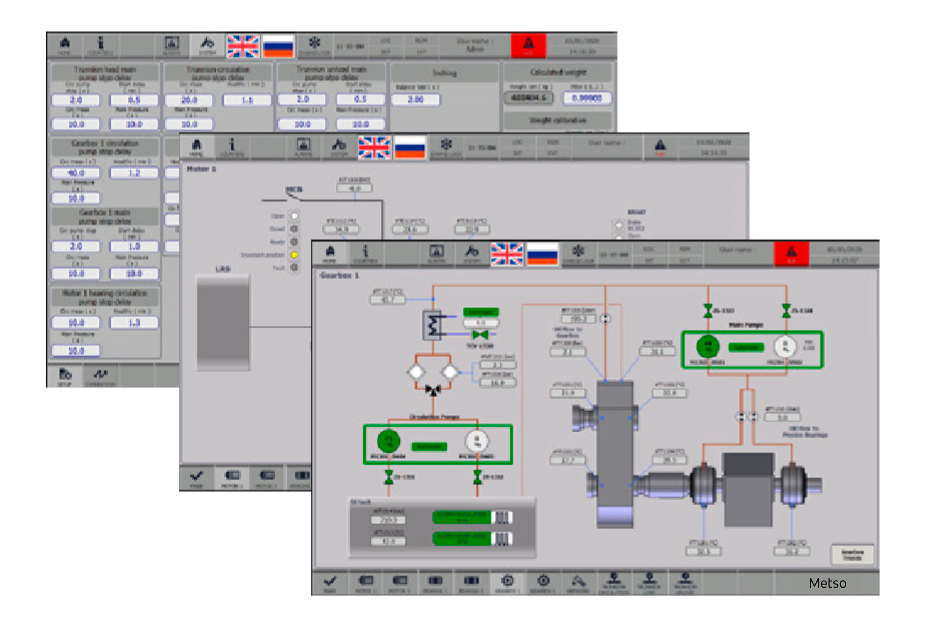

| 6 | System interface supports English, Russian, Spanish, and Chinese |

| 7 | Advanced condition monitoring system integrated into LCP |

| 8 | Infrared temperature monitoring of pinion gear |

|

Hardware components for Siemens platform |

Siemens S7-1500F fail-safe PLC |

|

Siemens TP1500 Comfort 15-inch full color touch panel | |

|

ProfiNet distributed I/O network to mill instruments | |

|

Siemens ET200eco IP67 field devices with IO-Link masters | |

|

Hardware components for Allen-Bradley platform |

Allen-Bradley GuardLogix Fail-safe PLC |

|

Allen-Bradley PanelView 5510 15-inch full color touch panel | |

|

Ethernet/IP distributed I/O network to mill instruments | |

|

Allen-Bradley ArmorBlock IP67 field devices with IO-Link masters | |

|

Installation requirements |

Indoor: Operating temperature: 0– 40°C |

|

Outdoor: Operating temperature: -15–55°C | |

|

LCP enclosure |

IP66/NEMA4 |

|

WHD: 800 x 2000 x 600 mm | |

|

Sheet steel, RAL 7035 | |

|

Power Supply |

Option 1: Single phase 120 to 230 VAC, 50/60 Hz |

|

Option 2: Three phase 380 to 500 VAC, 50/60 Hz | |

|

Interface options to plant control system |

OPC UA / Profibus DP / ProfiNet / Modbus TCP/IP / Ethernet/IP |

|

Interface options to mill motor control center |

Profibus DP / ProfiNet / Ethernet/IP |

|

Interface options to mill main variable speed drive |

Profibus DP / ProfiNet / Ethernet/IP |