Large top size acceptance

Up to 15% larger feed opening than similar sized crushers

Reduced construction height

Lower stations heights and space requirements

Multiple configurations

Split component options for above or underground applications

Crushing process optimization

SmartStation technology for optimal operation and station design

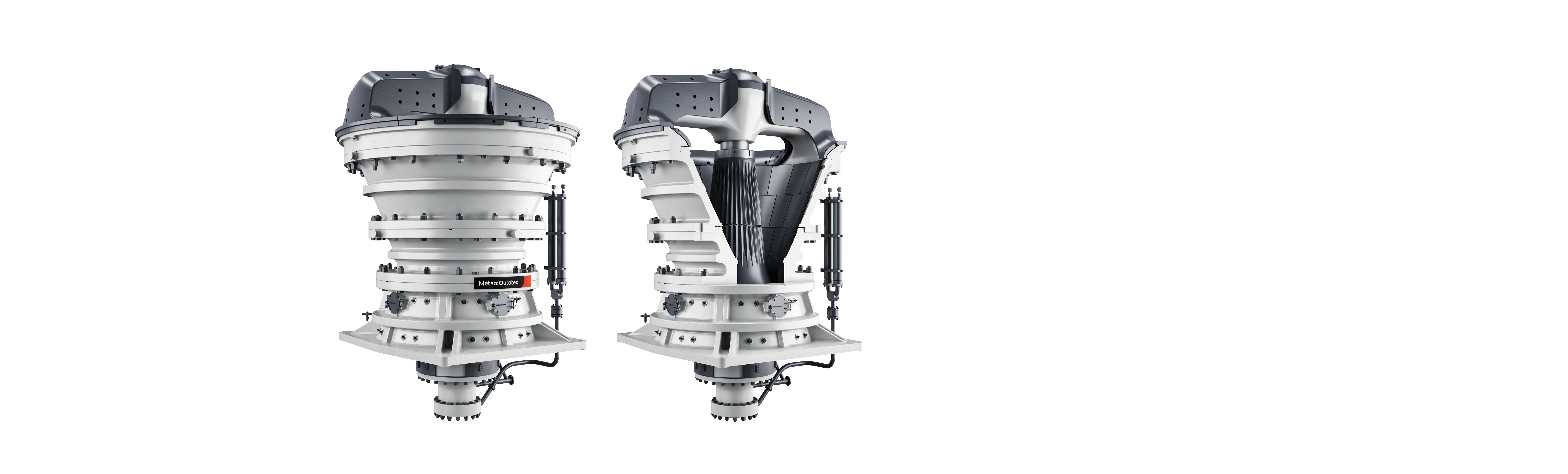

SUPERIOR™ MKIII primary gyratory crusher advantages

- Up to 15% larger top size acceptance than comparable size crushers

- Arched spider to minimize bridging

- Up to 300% more feed opening area compared to other compact gyratory crushers

- There is no need for oversized grizzly feeder or grid

- Up to 20% CAPEX savings

- Multiple feed point options

- Advanced controls to reduce vault height

- Shorter feeding point of crusher

- Ideal for both above and underground applications

- Multiple shell and spider configurations

- Compact components to fit into space-restricted areas

- Wide range of dismantle and transportation options

- Increase usable lifetime of concaves by up to 40% in single feed point applications

- Elimination of the requirement for a crane in rotating the top shells and spider to mitigate uneven wear distribution

- Increase uptime and operational efficiency

- Significant improvement in operator safety

SUPERIOR™ MKIII 6275UG technical specifications

Weight (kg) | Min. feed size (mm) | Length (mm) | Width (mm) | Height* |

|---|---|---|---|---|

| 280 000 | 1 440 | 5 700 | 5 600 | 4 650 |

| *Mounting plan to feeding point |