Developed over decades with a large global installation base and a wide range of cell sizes

Proven performance for all flotation applications allows for low total cost of ownership, high availability and reduced footprint

Comprehensive automation offering and lifecycle services play a key role in efficiency and productivity

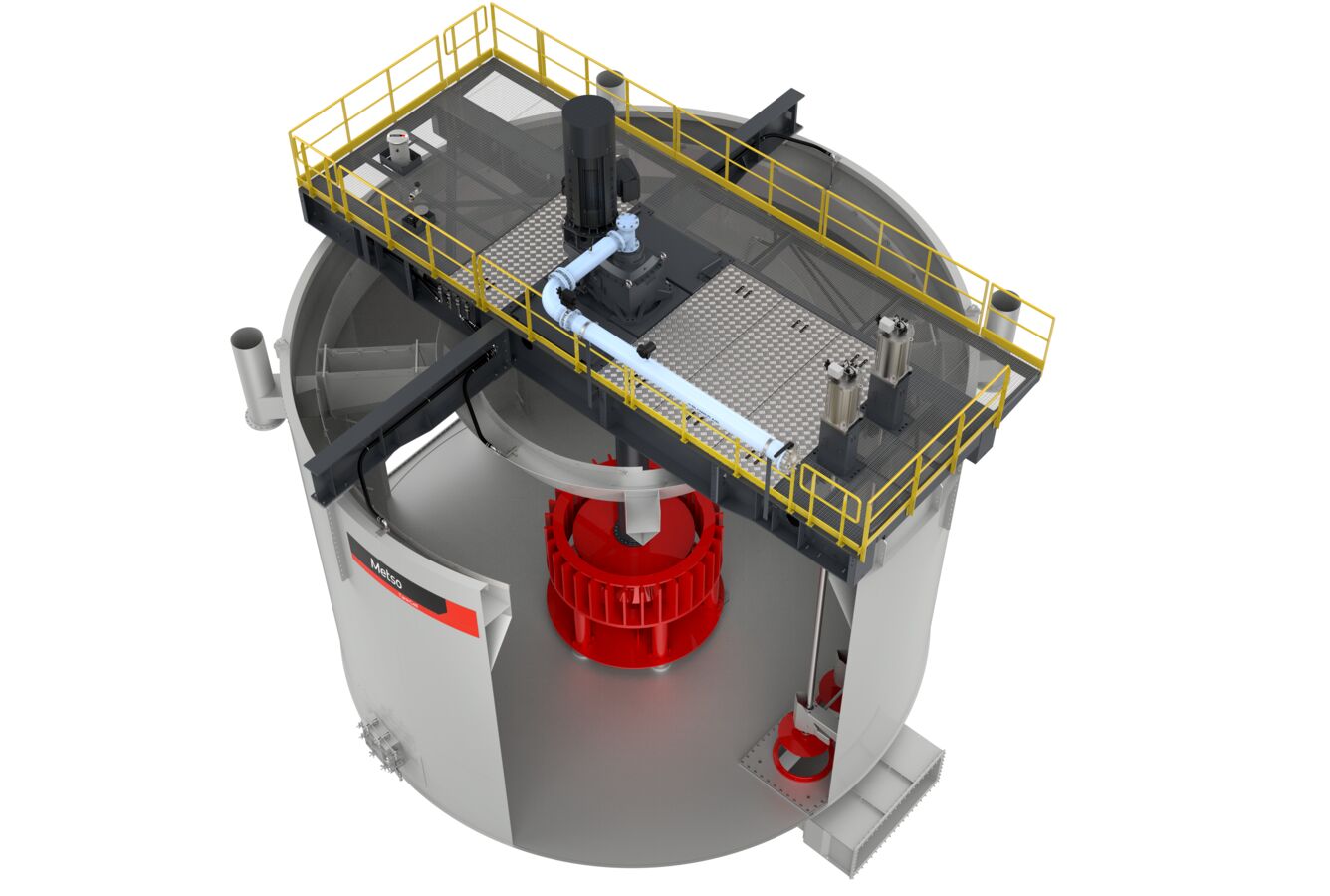

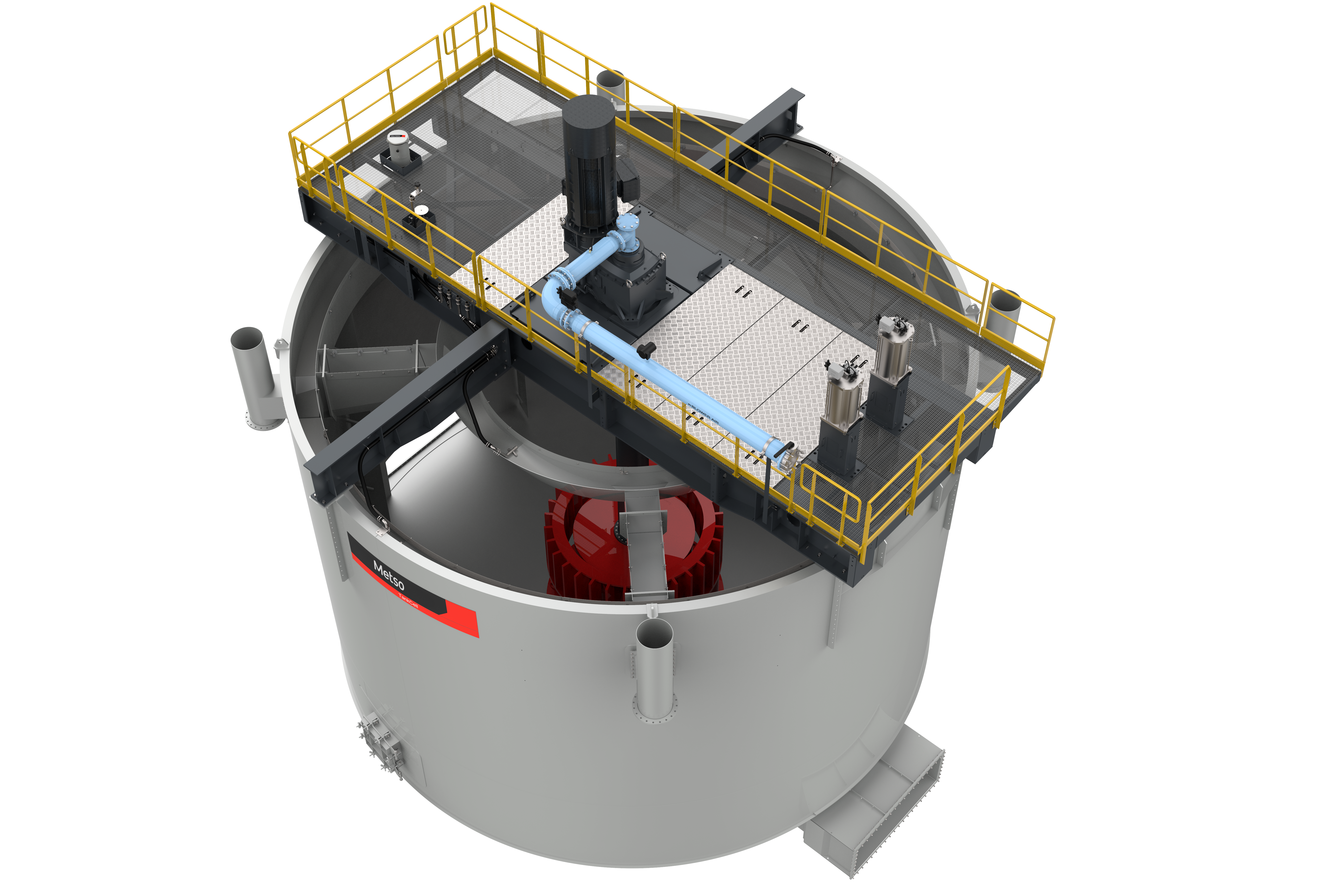

TankCell® flotation units provide superior metallurgical performance based on forced air technology, and are easy to operate while allowing a flexible layout.

Our solutions are designed to maximize your return on investment by enabling gains in throughput, grade and recovery, all whilst improving the sustainability of your process and minimizing its environmental impact at the same time.

- Lower energy consumption

- Reduced plant footprint

- High availability

- Less auxiliary equipment

- Proven superior metallurgical performance for all flotation applications

- Low cost of ownership

- Easy operation and maintenance

World’s best flotation performance

Parts & services

Improve metallurgical performance and energy efficiency while reducing operating costs with our rotor-stator mixing mechanism, FloatForce.

By improving flotation hydrodynamics and pumping performance at high air dispersion rates, the FloatForce enhances particle recovery in the flotation cell while reducing power consumption and the risk of sanding at the same time.

The mixing mechanism performance has a direct impact on the three key areas of flotation, which are metallurgical performance, energy consumption and operating costs. The design features wide pumping channels with separated air dispersion slots to ensure optimal mixing efficiency.