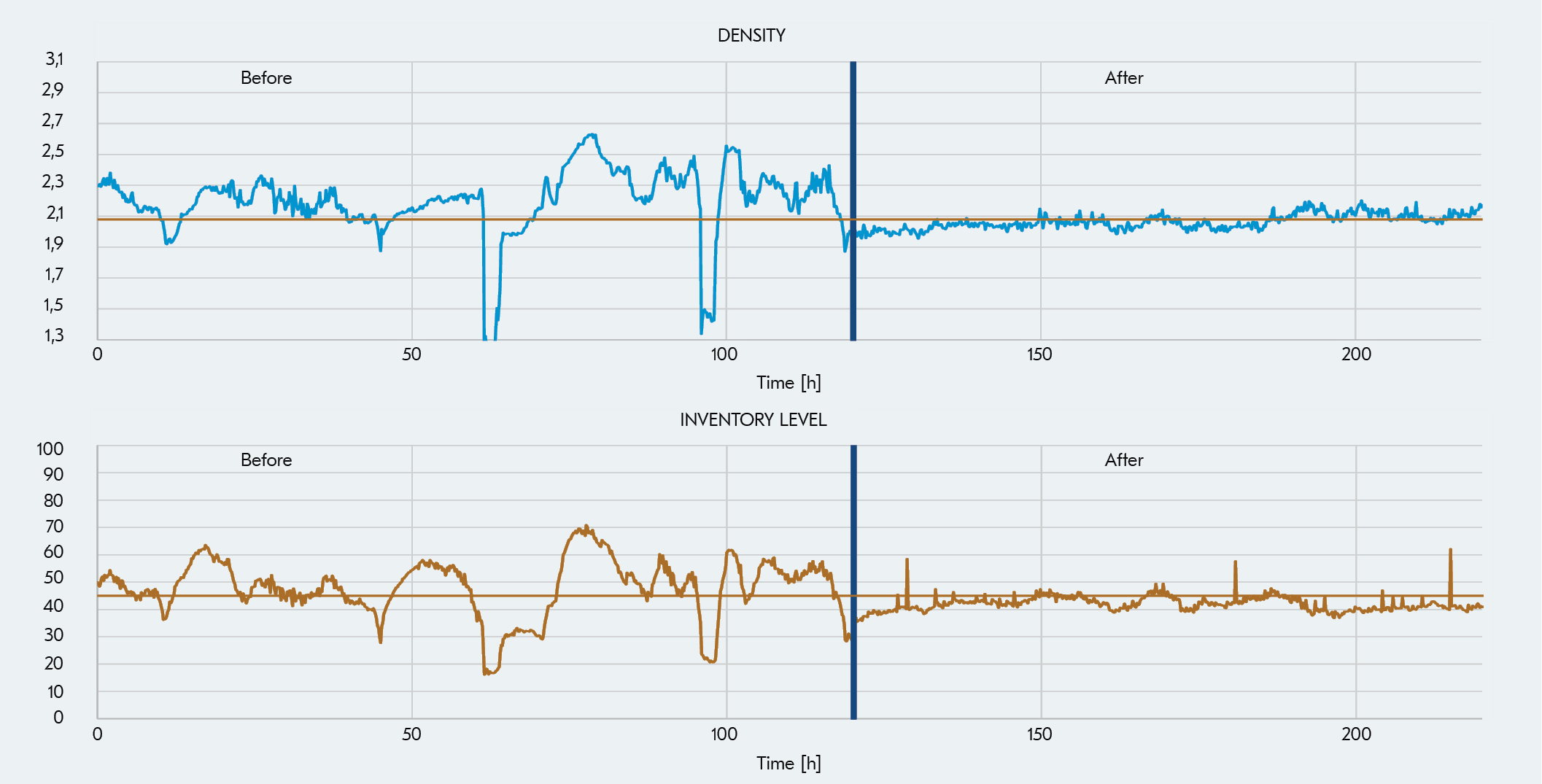

Improving process stability is the key to process control. Thickening is, by nature, a slow process with multiple variables influencing process performance. For example, when the feed mass flow and its properties change, timely adjustments are needed to maintain a stable output. This requires a good understanding of process dynamics and overall process behavior.

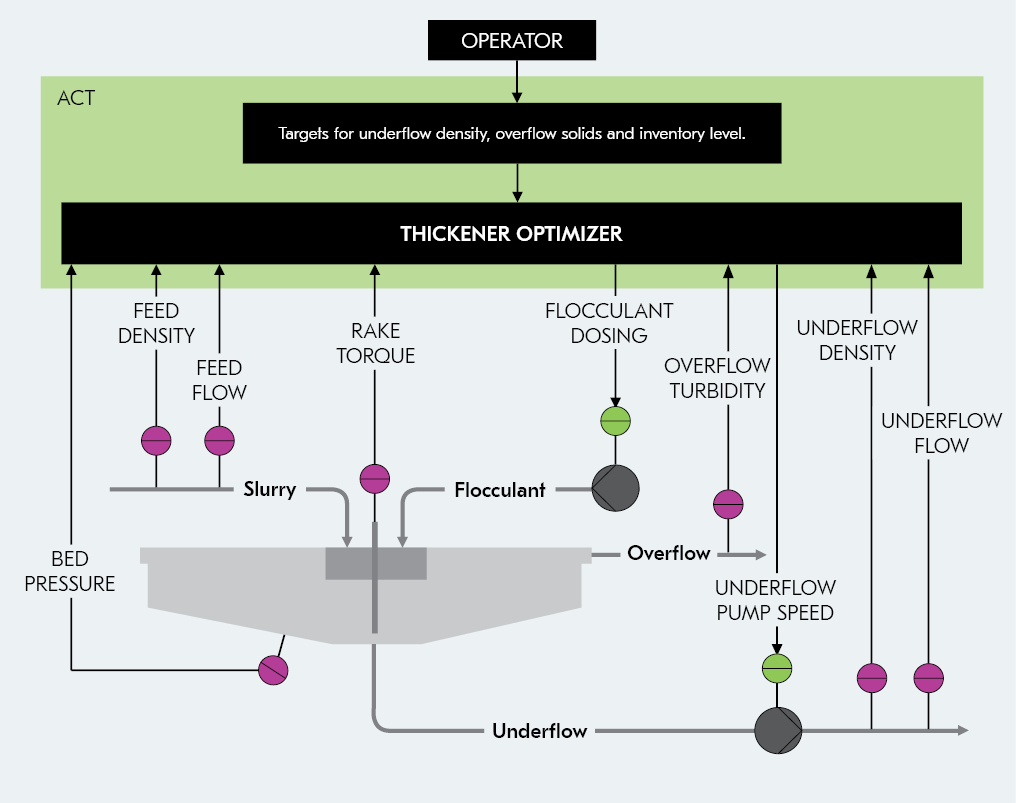

Traditionally, thickener controls are implemented as single-loop controllers in plant control systems. Based on our experiences from numerous thickener installations, this approach has several drawbacks, which easily lead to sub-optimal process performance. The Thickener optimizer overcomes these limitations, and combines our thickening experience with a multivariable, model-based controller. The Thickener optimizer is based on our proven proprietary APC platforms.

The Thickener optimizer controls:

- Underflow density

- Overflow solids content

- Thickener inventory level

The Thickener optimizer utilizes measurements available from the process, and manipulates the underflow pumping rate and flocculant dosage to maintain a stable process. Information from the thickener feed line – the input flow rate and slurry density – is used when available. To avoid critical rake loads, the rake torque is also taken into account.

Applications:

- Concentrate thickeners

- Thickened tailings

- Paste thickeners