Maximize your thickener and clarifier performance

Discover everything you need to know about keeping your thickeners and clarifiers running at peak efficiency.

Parts are quality tested to ensure safety and trouble-free operation

With 150 distribution centers worldwide, we supply parts where and when you need them

From recommended parts lists to installation to upgrades through the entire life cycle of your equipment

From original to 3rd party parts, to complete kits, we can support your site

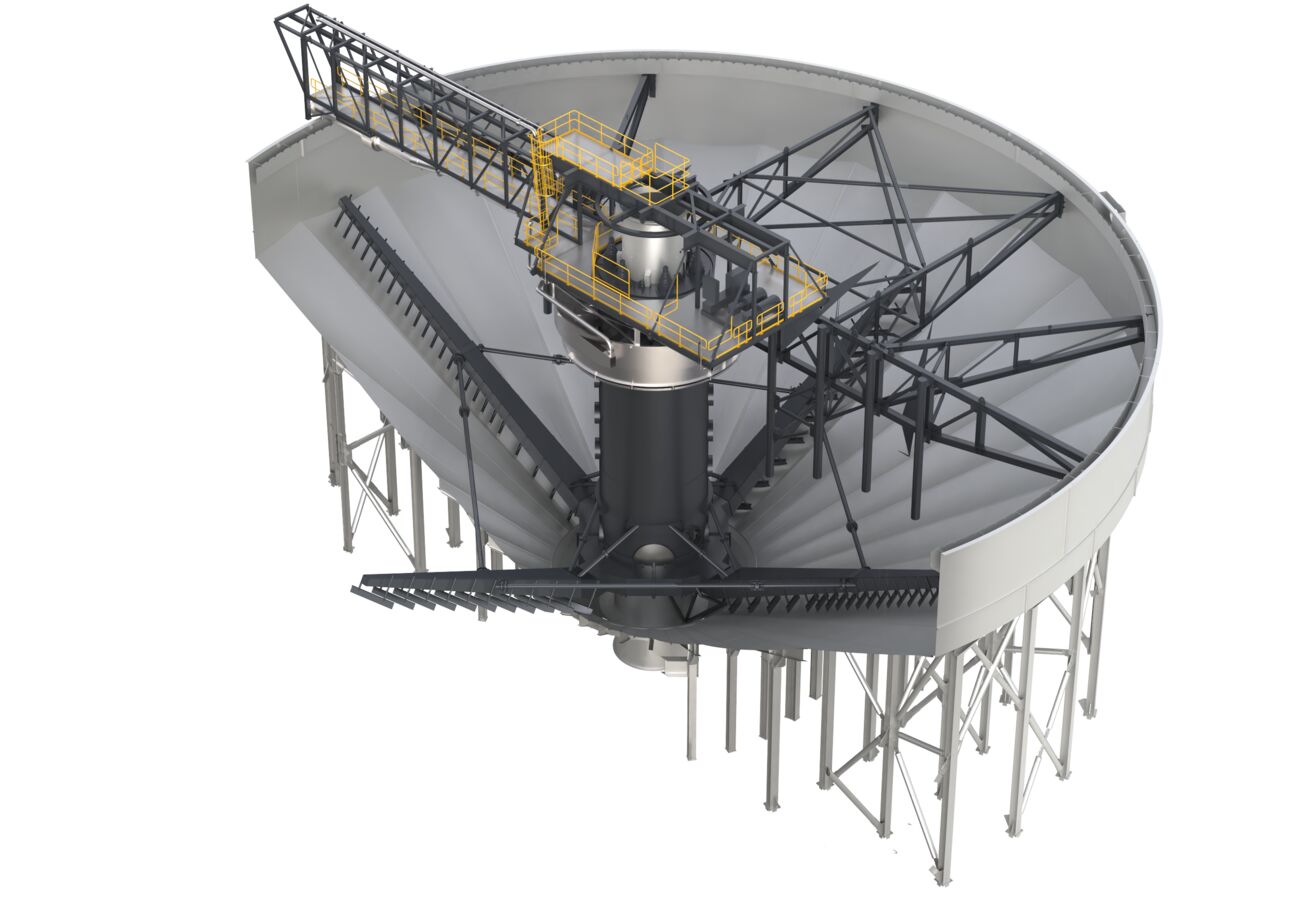

Metso has a proven history in designing, manufacturing, servicing and supplying components for thickeners and clarifiers. We are market leaders in the industry with our extensive range of products and are flexible service partners. We can supply the following standard and custom component orders for:

A breakdown on a thickener can be critical for the operation of the mine site. Having a reliable parts supply on hand is essential to your operations. Some thickener spares are custom manufactured and thus can have longer lead times. We, therefore, recommend stocking the following vital components to ensure the optimal functionality and availability of your thickener:

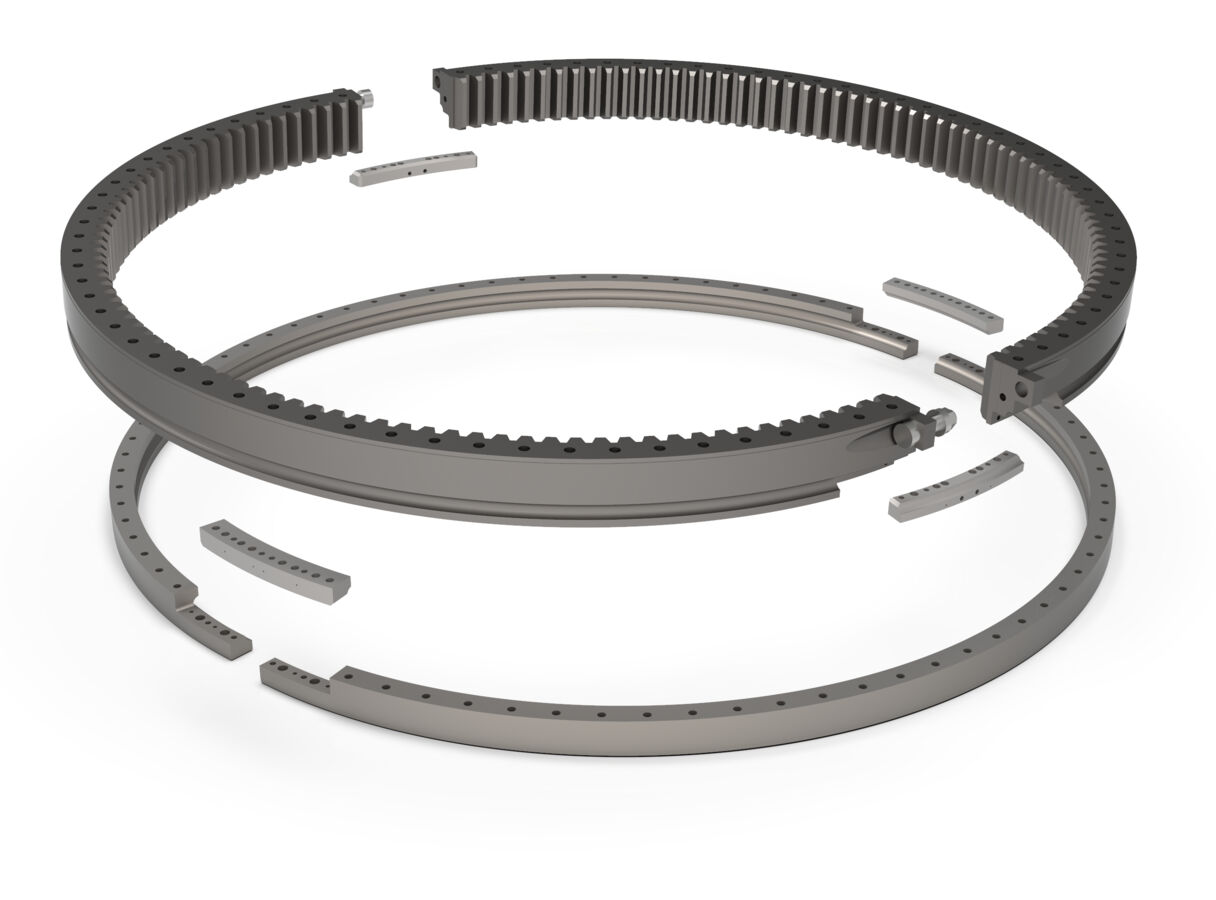

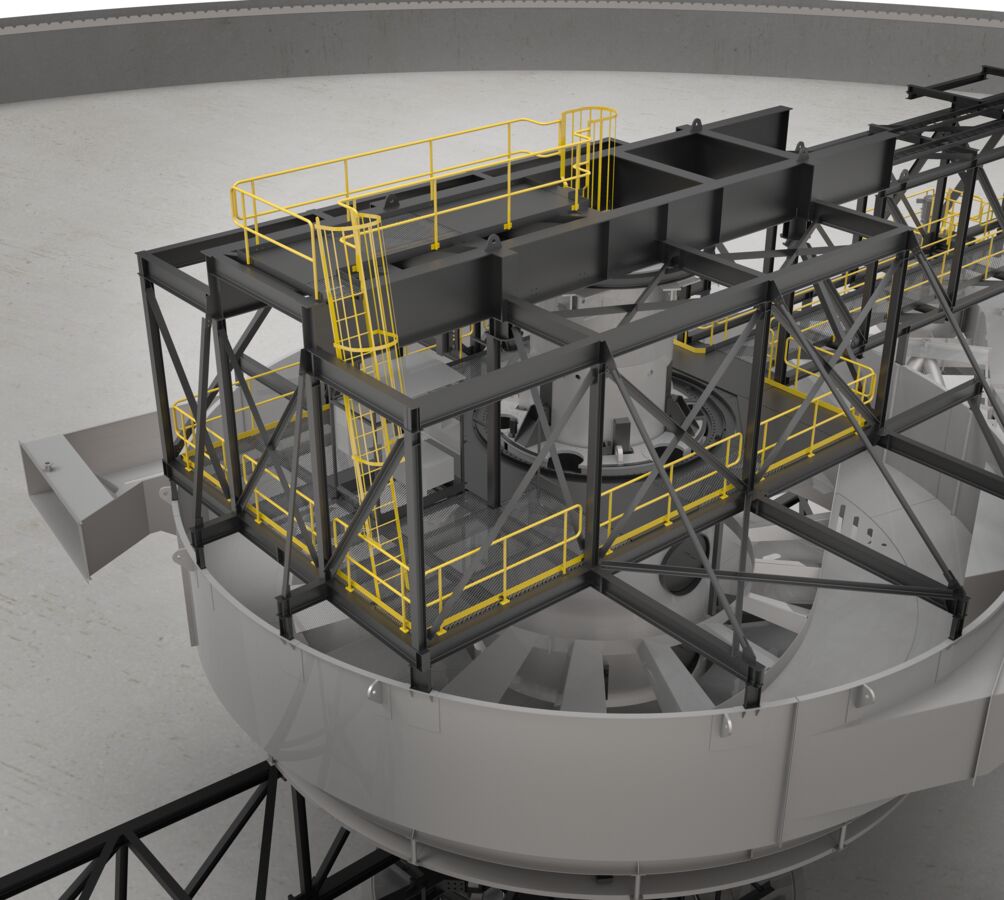

The rake mechanism is used to move the settled solids (also called the slurry) toward the center of the tank where they can be removed. The rake mechanism consists of a series of rakes that are suspended from multiple rotating arms. As the arms rotates, the rakes move through the slurry and push them toward the center of the tank. Some of the main components are:

*Vital spare part

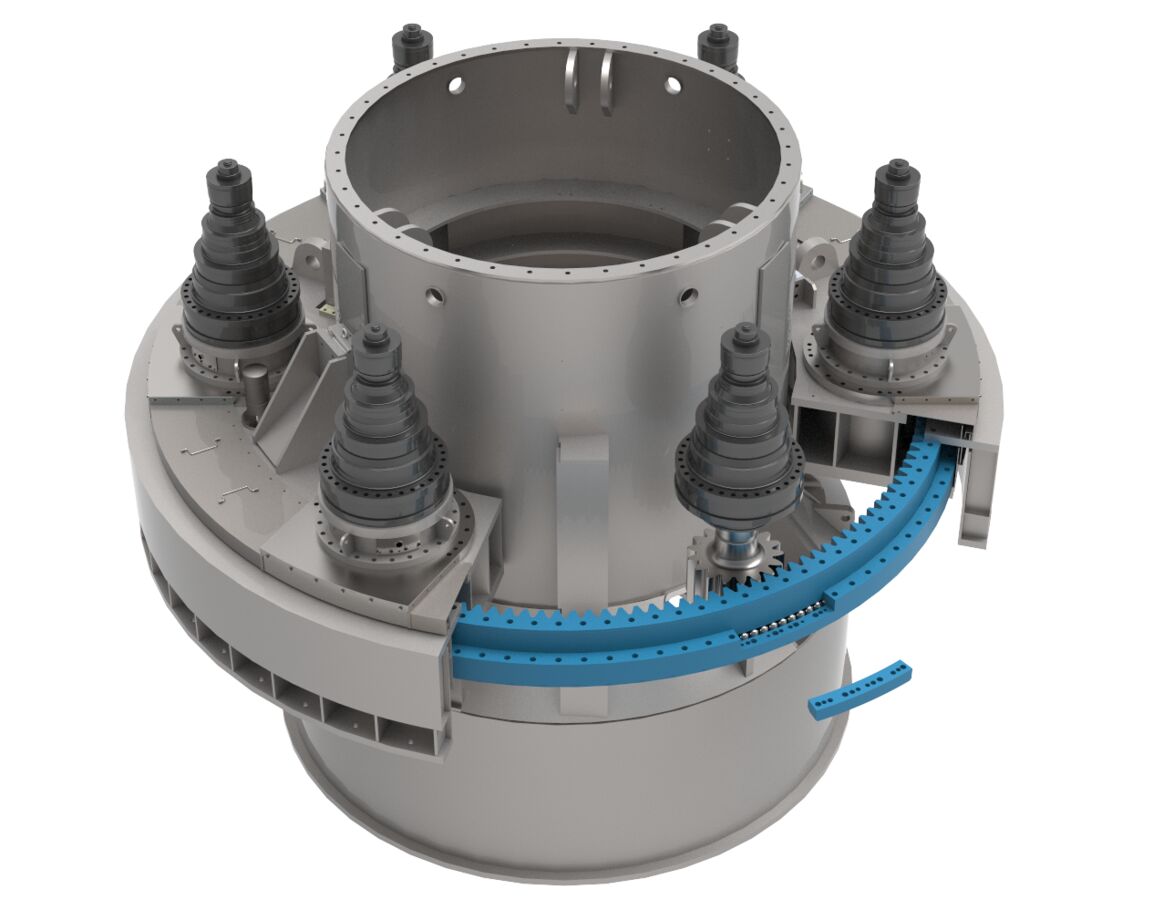

The thickener drive unit is the mechanism that powers the movement of the rake mechanism in a thickener. The drive unit is typically located at the top of the thickener tank and has a robust design to handle significant hours of operation. This design allows for ease of service and replacement of spares. Below are some of the common spares;

*Vital spare part

Instruments are used to measure parameters for safe operation and control of the thickener, including measurements of the feed density, overflow clarity, feed flow rate, rake height and solid settling. The below instruments are necessary for your thickener:

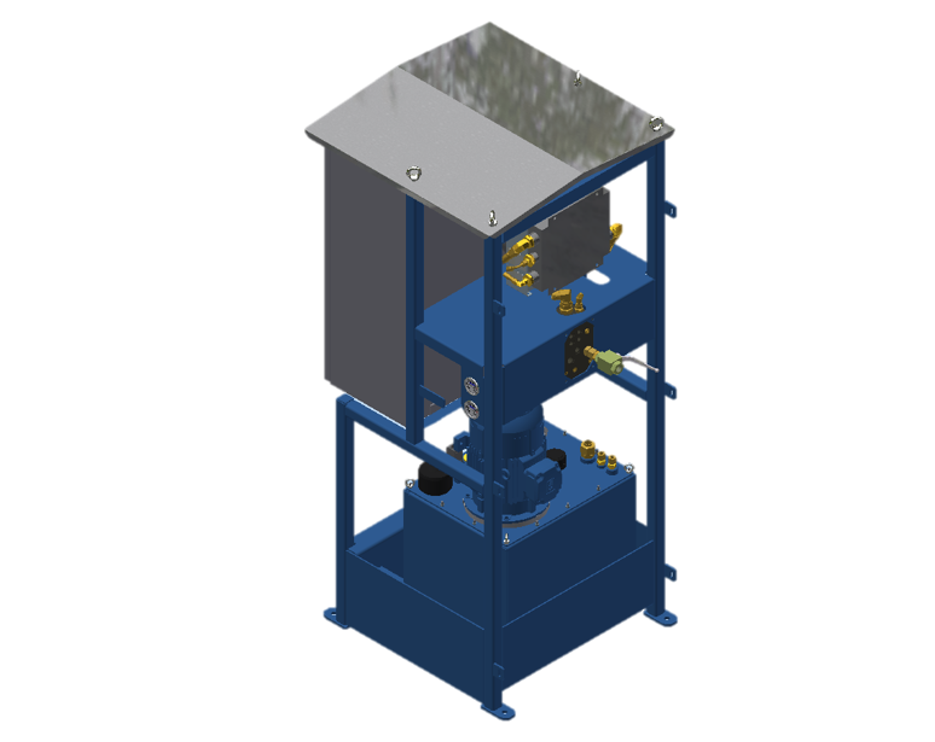

The hydraulic power unit (HPU) is a mechanical device that uses hydraulic pressure to transmit power to the drive unit and force the rake to lift. The HPU is an integral part of the thickener drive system, below are some of the common spares:

*Vital spare part

**Upgrade

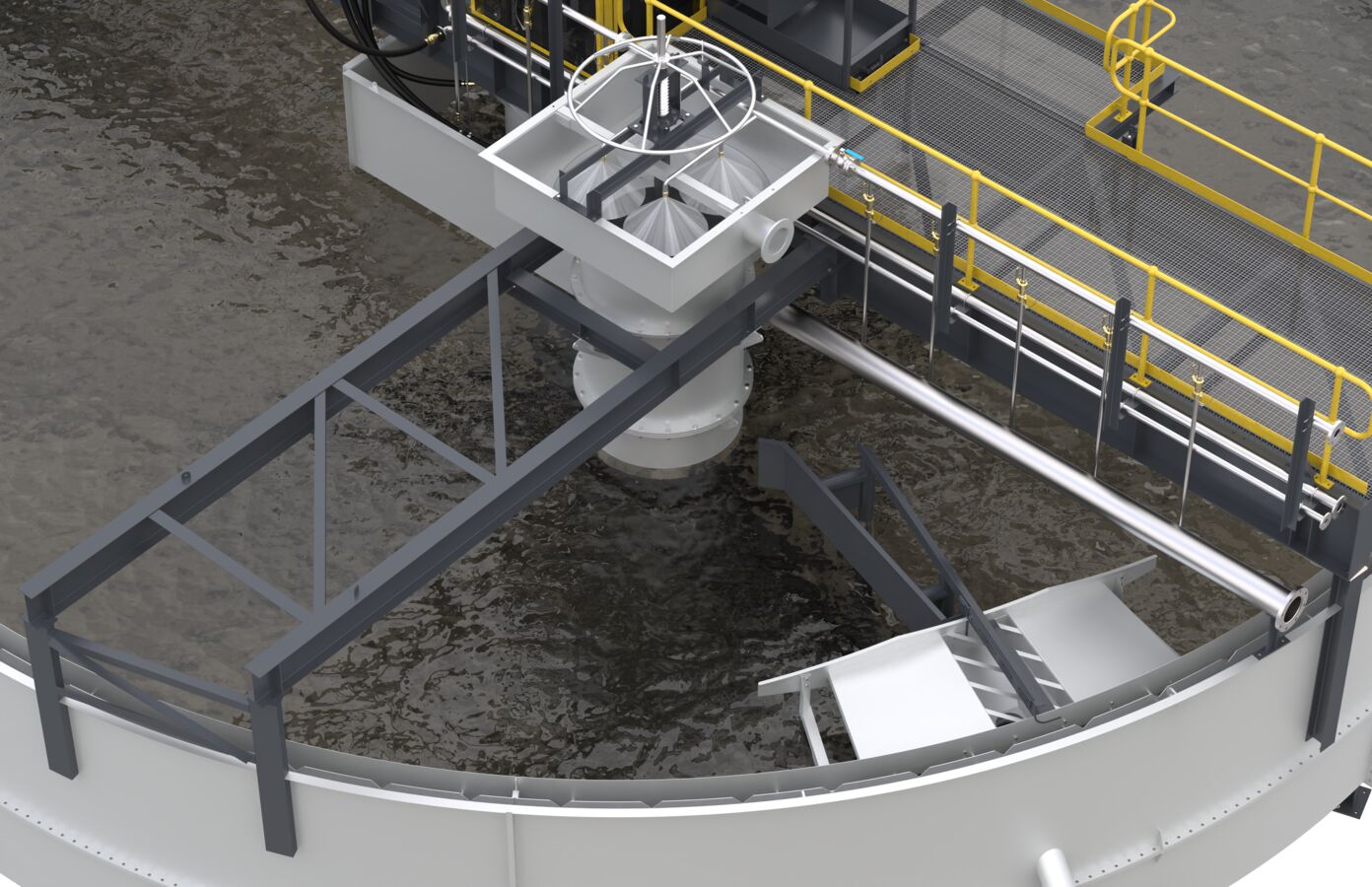

The feed system comprises a critical set of components that have a significant impact on the overall thickener performance by ensuring the feed material is properly conditioned before being introduced to the thickener. Major feed stem components include piping, feedwell, the flocculant distribution system and any components fitted to increase feed dilution. Some of the standard spares found in the feed system:

Read more about the feed system here>>

Froth that accumulates on the thickener surface usually represents unrecovered valuable minerals. Froth can also reduce thickener process performance (overflow clarity/underflow density) and impact the efficiency of adjacent processes such as flotation and filtration. Excessive froth also leads to increased plant maintenance work and cost due to the accumulation of solids in the systems that handle process water - such as blocking of sprays and build-up of solids in process water tanks.

We have systems that reduce froth using some of the following components:

Read more about froth management here>>