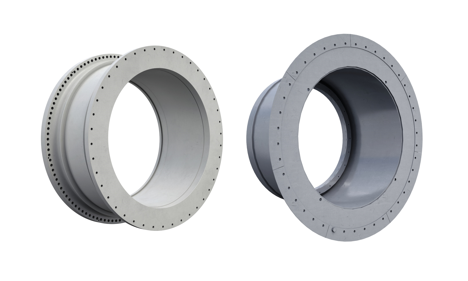

Metso values continuous improvement and strives to redefine the industry standard in mineral processing technologies. The Metso trunnion liner upgrades originated through this process, offering an old for a new replacement of existing one-piece trunnion liners for a new and improved multi-piece trunnion liner configuration.

The effectiveness of this design has been tried, tested and proven to improve durability, sustainability and serviceability of the mill feed and discharge ends, consequently making it the current standard design for all new Metso mills.

Modernization solutions are one of many key services offered by Metso to ensure that our customers maintain the optimal performance of their equipment. The trunnion liner upgrade belongs to this product portfolio, providing proven benefits to applicable Metso grinding mills.

Reduced operating and maintenance costs

Are you changing trunnion liner fasteners due to damage? Or, having to replace the entire trunnion liner due to localized lining wear?

Decrease operating costs through optimized wear components associated with the trunnion liner upgrade. The trunnion liner upgrade has been developed primarily to reduce maintenance costs through its multi-component configuration. The multi-piece design optimizes load conditions through the trunnion liner thereby improving fastener durability. Dividing the trunnion liner into multiple pieces enables the replacement of the consumable component only, consequently reducting ongoing consumable costs.

Improved process availability

Have you experienced mill downtime due to lengthy trunnion liner replacement or trunnion liner removal for trunnion bearing replacement?

Reduce lost production time with the trunnion liner upgrade. The multi-component liner design enables quick removal of the trunnion liner retaining ring, allowing unrestricted access to the bearing without the need for removing the entire lining.

Service description

The Metso trunnion liner upgrade is old for new replacement components and can readily be supplied to the site; however, as with all retrofit devices, we recommend a site inspection to confirm that the trunnion is still in as-designed condition. This will ensure the validity of the product design for your site to reduce the risk of unforeseen issues during installation and plant downtime.

All site visits will be scheduled to the mutual convenience of your plant’s designated contact person and a Metso representative. Metso shall remain reliant on the customer to ensure that the plant is available for the inspection visit at the scheduled time.

Outputs and resulting actions

Our team of qualified technicians and engineers work together to develop the best solution that serves our customer’s needs in the best possible way.

What you can expect?

- Feedback about any potential issues identified during the pre-design mill inspection

- Trunnion liner assembly designed specifically for the application

Additional Metso service offerings to complement the trunnion liner upgrade

- Installation

- Commissioning