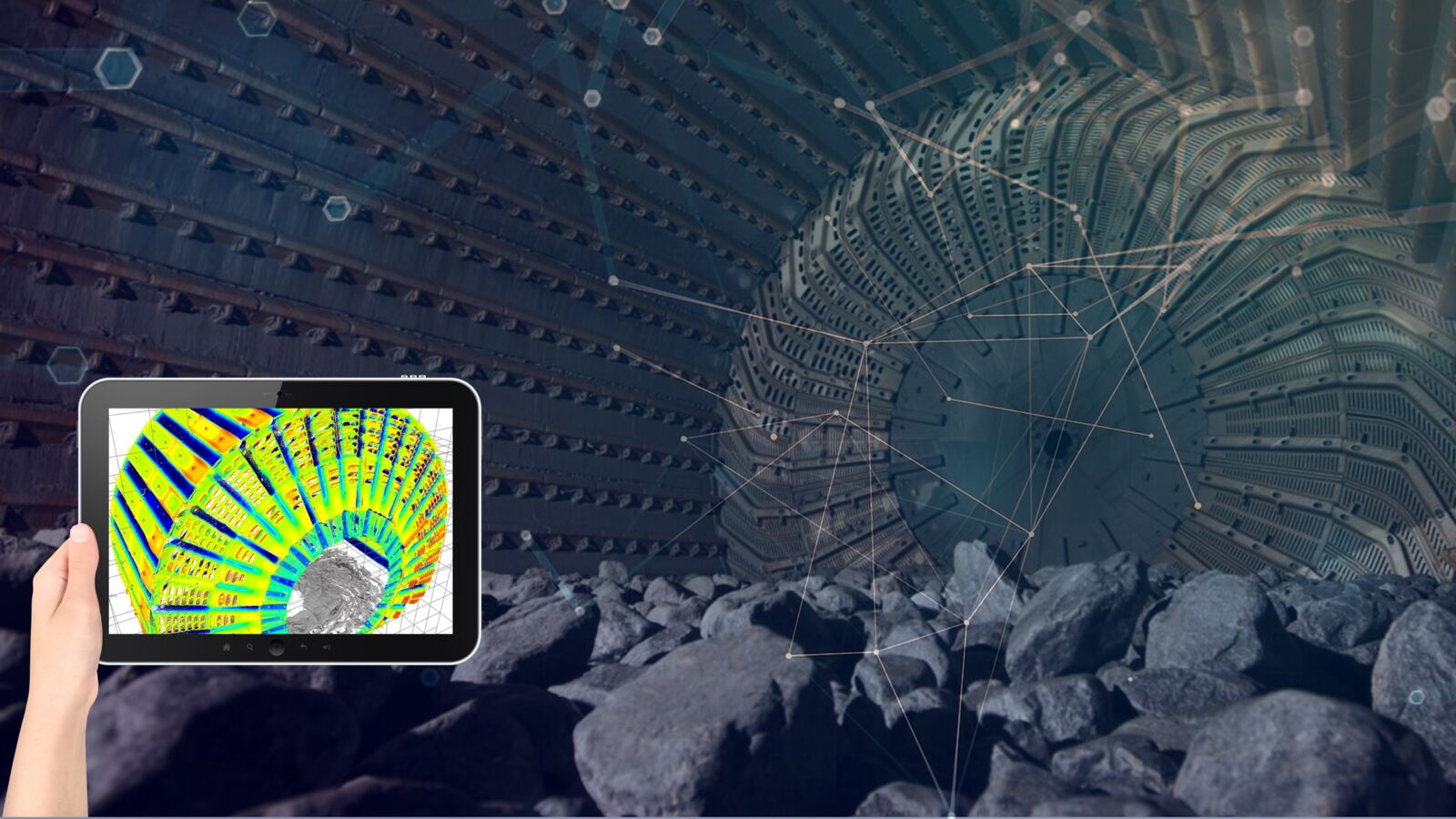

Grinding process optimization and connected services

Explore our tools to aid in optimizing your circuit to increase throughput, availability, or reduce energy consumption.

Supporting your operations, from plant design expertise to equipment, parts and services for every stage of your process.

Are you looking to increase production, reduce risks, lower operating costs and enhance environmental performance? Then you are in the right place.

From the design and supply of products for a greenfield plant, to the addition of a single machine for an existing production line, we are here to help.

Rely on OEM experts because not all parts are created equal. Spare and wear parts built to perform.

Helping you get the most out of your equipment and processes.

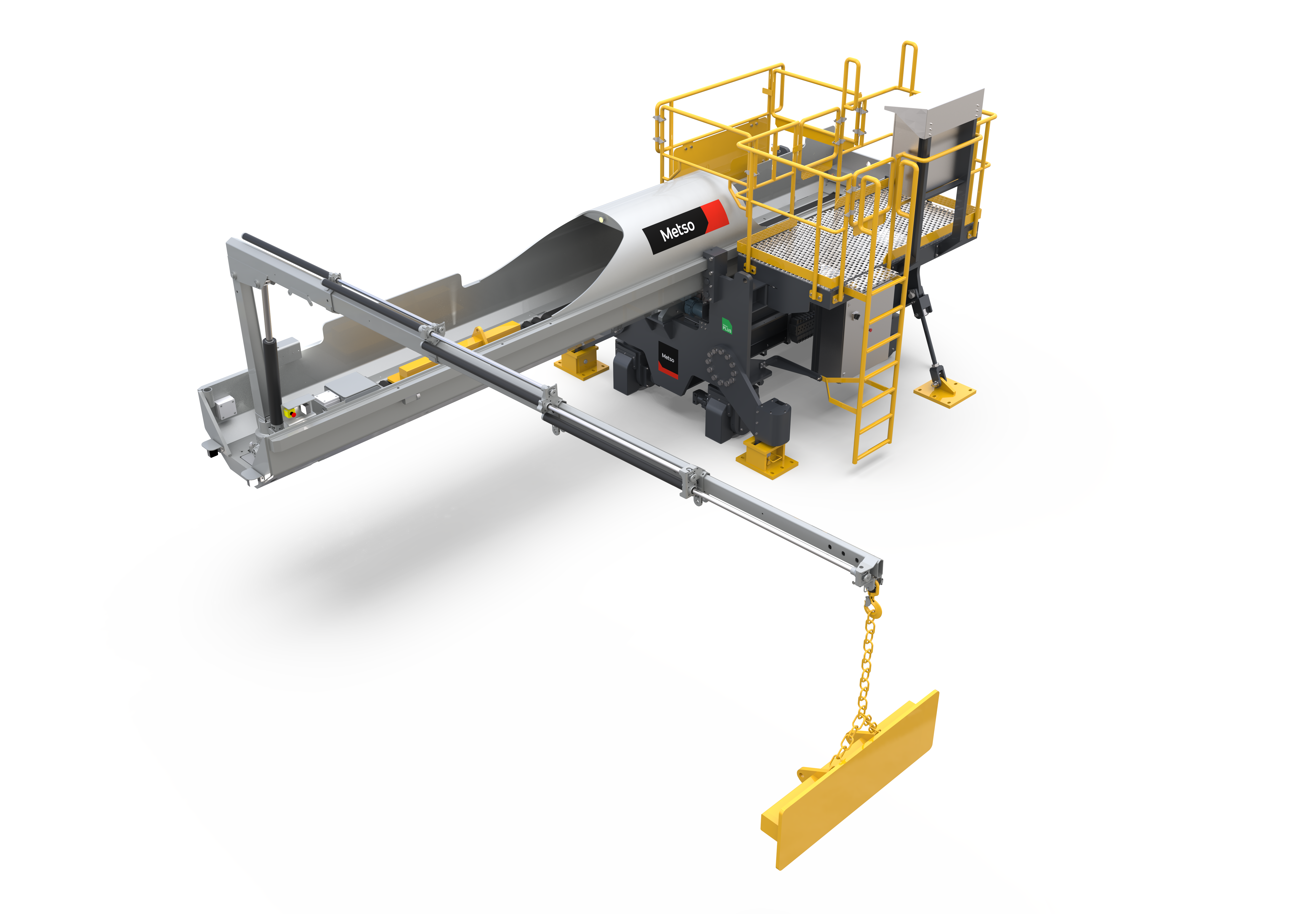

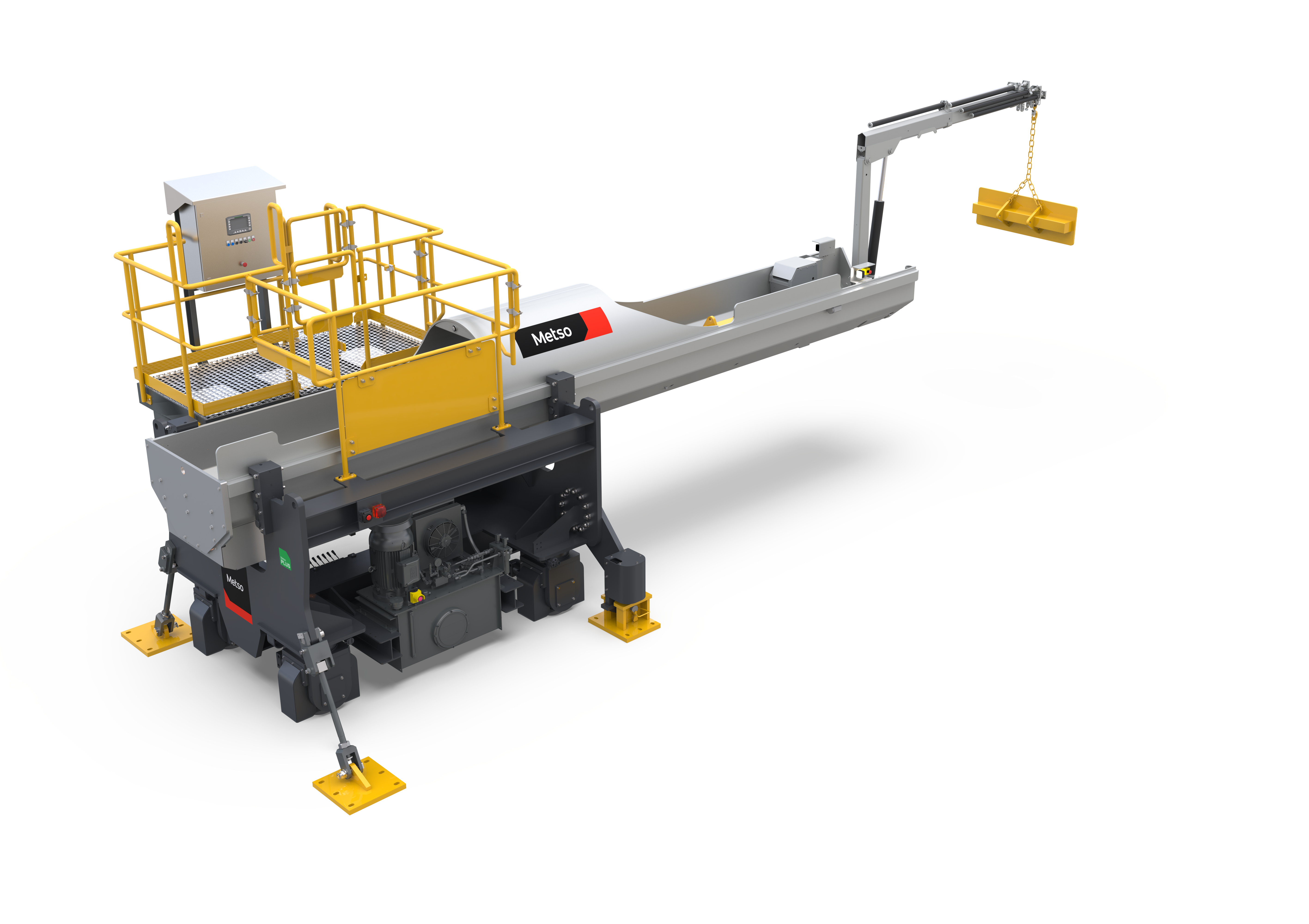

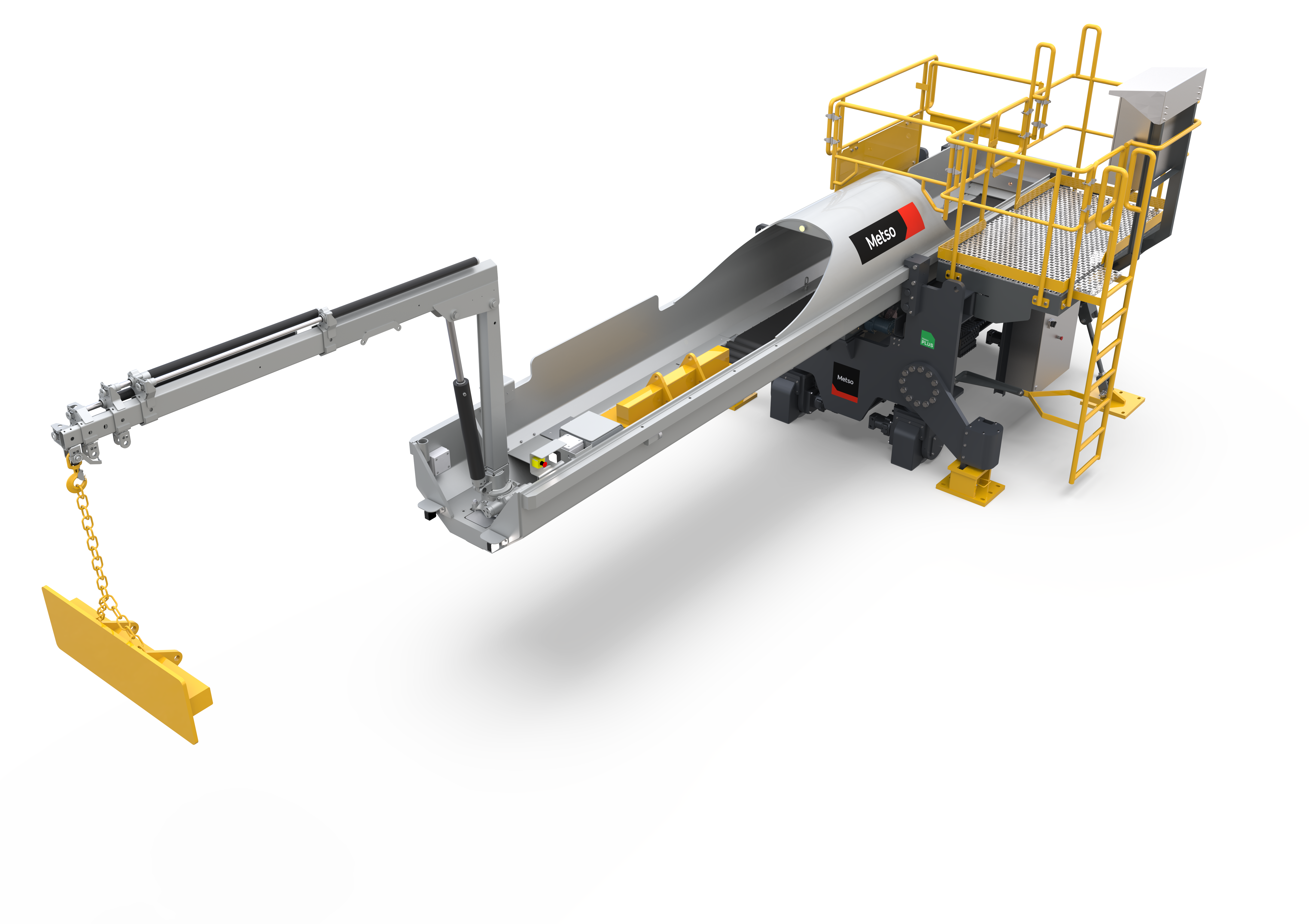

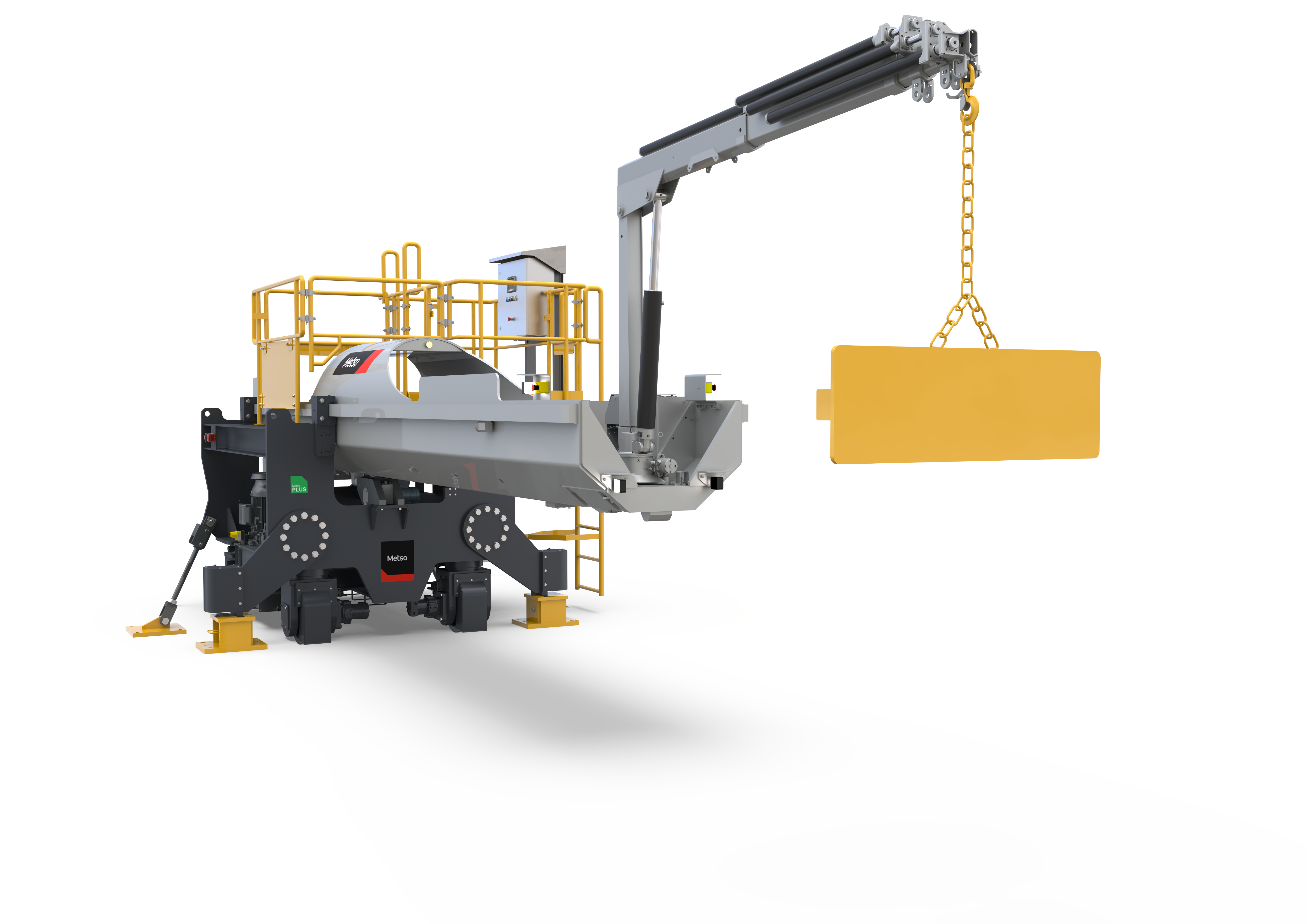

The patented tube design minimizes the required mill opening size while maximizing the usable open area for liner delivery. The Tube MRM features industry-leading safety systems and is backed by Metso’s full range of support services.

Mechanical assistance is a critical requirement for safe relining and is often challenging in smaller SAG and ball mills. The Metso Tube MRM provides fixed three-axis hydraulic crane support for relining tasks in mills that are unsuitable for traditional reline machines. This ensures stable lifting and minimizes time lost during mill inching.

The main tube structure maximizes both the structural support through small mill openings and the open space available for liner delivery. This streamlines the relining process by allowing the machine to use a high-capacity crane and large liner designs. The simple tube design decreases both maintenance requirements and machine cost due to the reduced number of moving components.

A range of safety systems is provided as a standard to provide the highest possible level of protection for personnel. Rated capacity limiting and installation monitoring mitigate the risk of instability and overload during operation, while remote-control operation and hydraulic spool monitoring prevent unexpected machine movement. All safety systems can rapidly cut hydraulic power if a dangerous situation is detected.

Please note that the figures below may vary depending on the delivery scope. Contact your local sales representative for exact figures

|

Capacity |

|

|

Crane |

|

|

Safety systems |

|

|

Drive system |

|

|

Control |

|

|

HMI Screen |

|

|

Liner transport options |

|

We collect and process your data on this site to better understand how it is used. You can give your consent to all or selected purposes or decline the non-essential ones. Essential cookies, which are necessary for the basic website functionality such as page navigation, cannot be declined. Without these cookies, the website would not function properly. For more details, please refer to our Privacy Notice.

Privacy Notice