Read the customer case

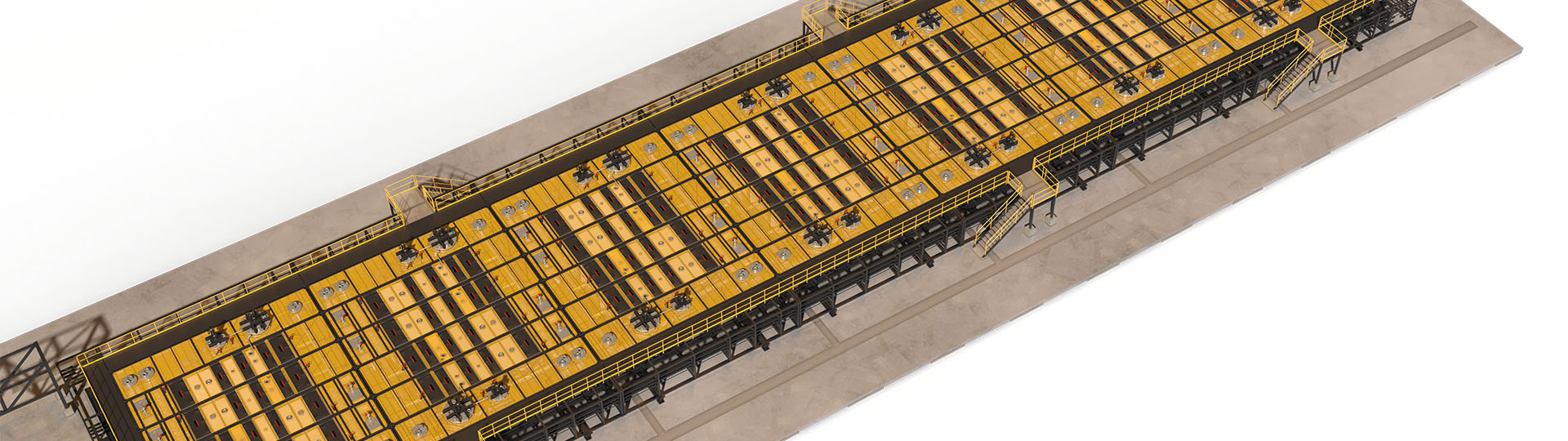

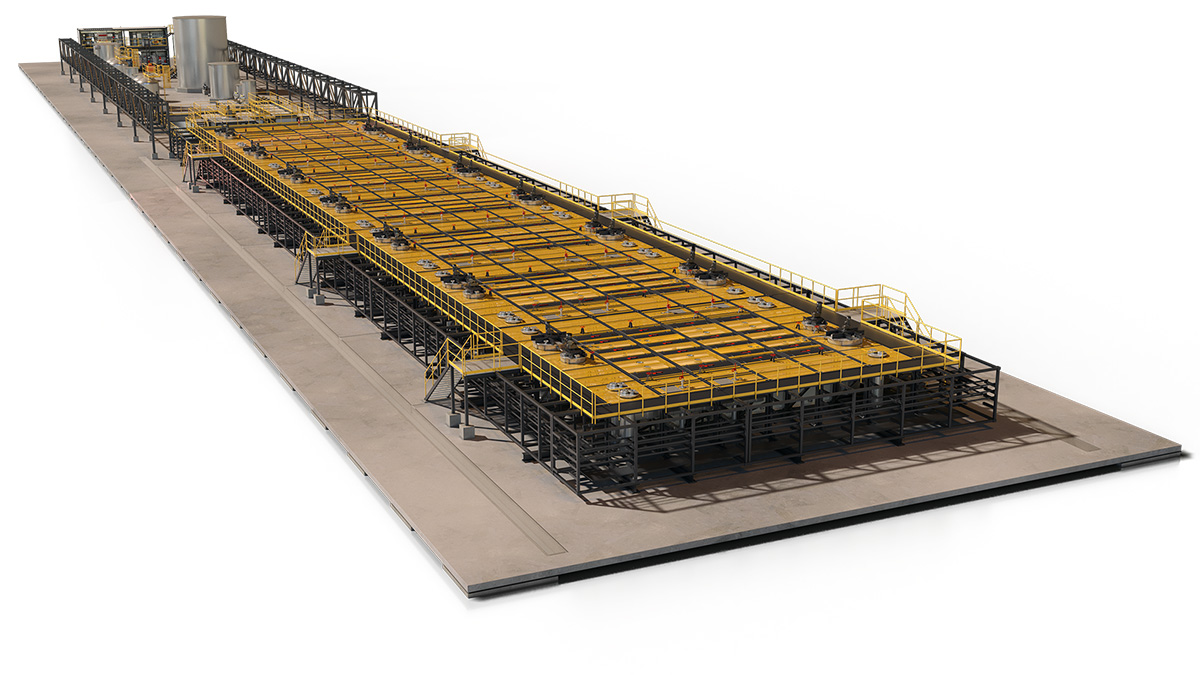

How Metso's leading-edge SX-EW technology is helping to maximize Rol at the world's largest SX facility, Grupo México’s ESDE III copper SX-EW plant

Proven process and technology with industry’s most comprehensive scope of supply

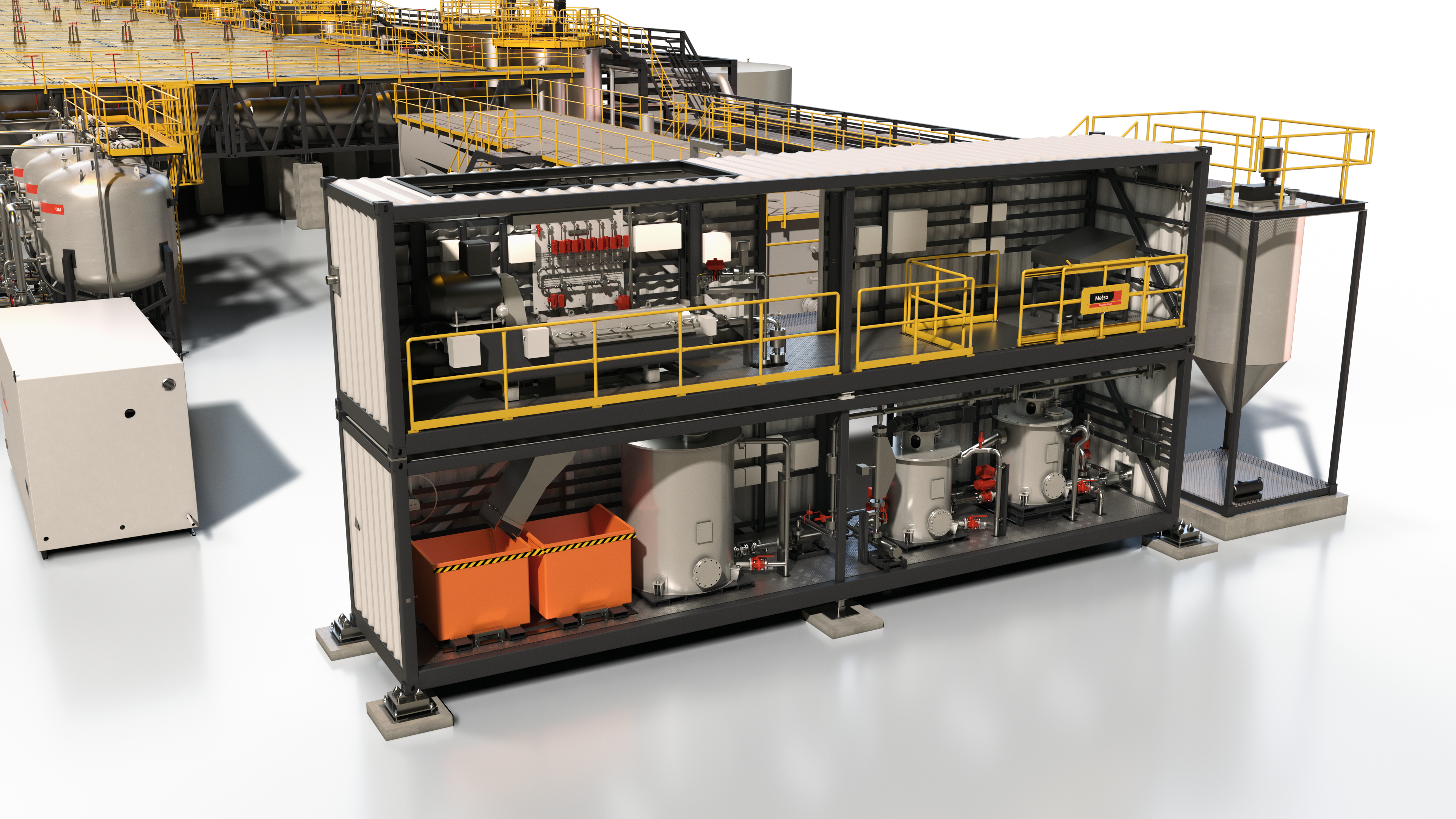

Efficient modular design and delivery

Safest solvent extraction plant for the operator

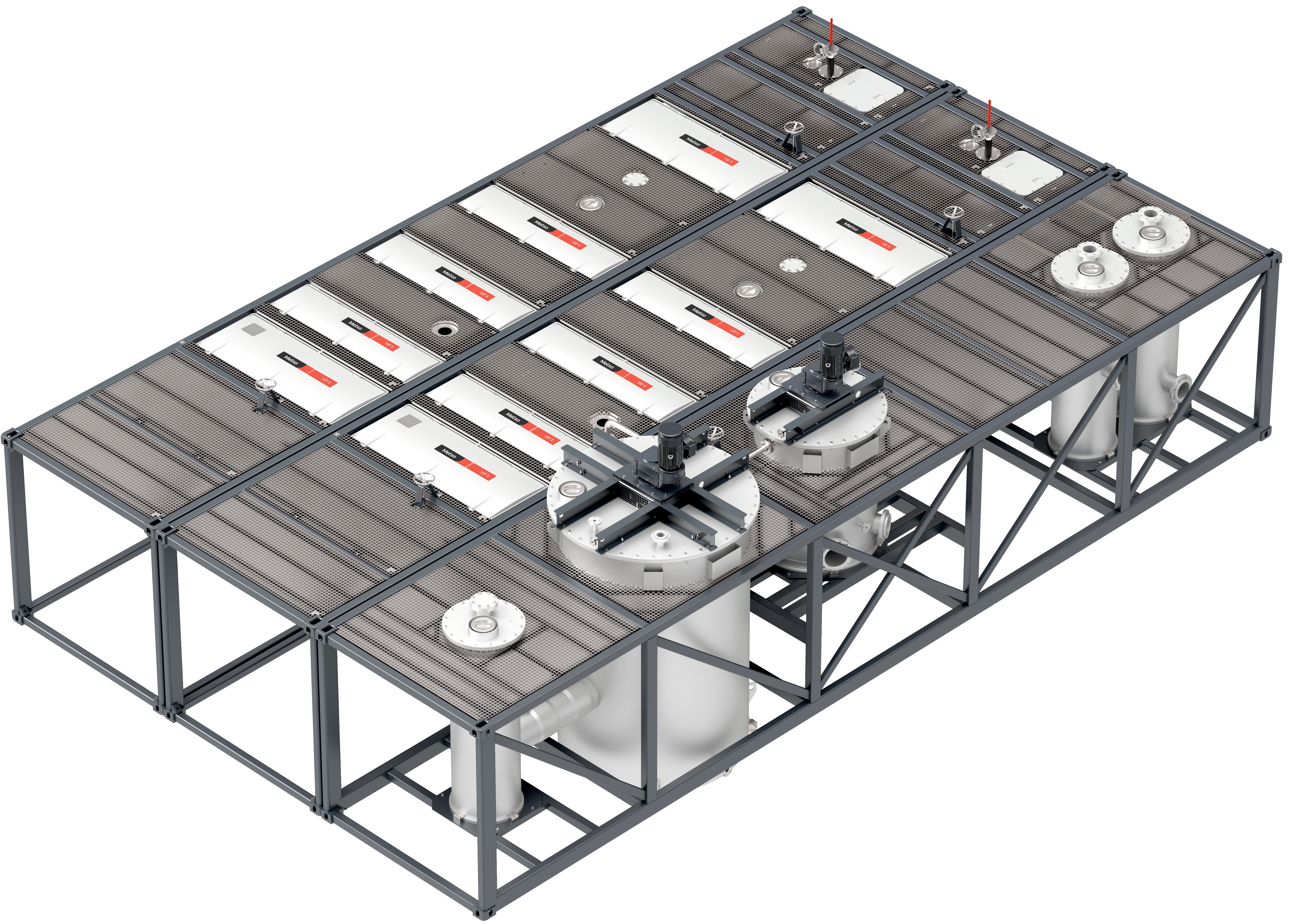

Metso is a technology provider that offers a fully tailor-made flowsheet and a wide range of highly productized modular VSF® X equipment for the solvent extraction plant.

With decades of technological experience and a proven concept, our modularized and sustainably designed VSF® X solvent extraction plant offers excellent scalability, high quality, fluent logistics, fast delivery and an inherently safe design all backed by performance guarantees.

Our VSF® X solvent extraction technology has been globally utilized in flowsheets, processing complex ore bodies, to purify the pregnant leach solutions (PLS), resulting in proven production of high grade Cu cathode and Ni, Co, and Mn battery chemicals.

Core | Auxiliary | Enablers | Services |

|---|---|---|---|

|

VSF® X solvent extraction equipment: | OKTOP® pre-neutralization reactor | Spare parts | |

|

VSF® X mixer-settler | Courier analyzer | Core basic engineering | Startup |

|

VSF® X organic tank | Dual Media (DM) filter | Geminex™ metallurgical digital twin | Troubleshooting |

|

VSF® X after settler | Activated Carbon (AC) filter | Flowsheet development and studies | |

|

VSF® X organic and crud treatment unit | GM filter | Kinetic batch testing of leaching | |

| Backwash tank | Pilot testing | ||

| Metso proprietary digital solutions for solvent extraction plant: | |||

|

OA Sense |

The organic and crud treatment unit is a ready-made auxiliary treatment unit for the VSF® X plant. Designed to treat both formed crud and oxidated organic and return separated liquids back to the process. It enables efficient and continuous VSF® X solvent extraction process and is easily integrated to VSF® X plant.

Core differentiators:

Metso VSF® X solvent extraction is part of the Metso Plus product portfolio.