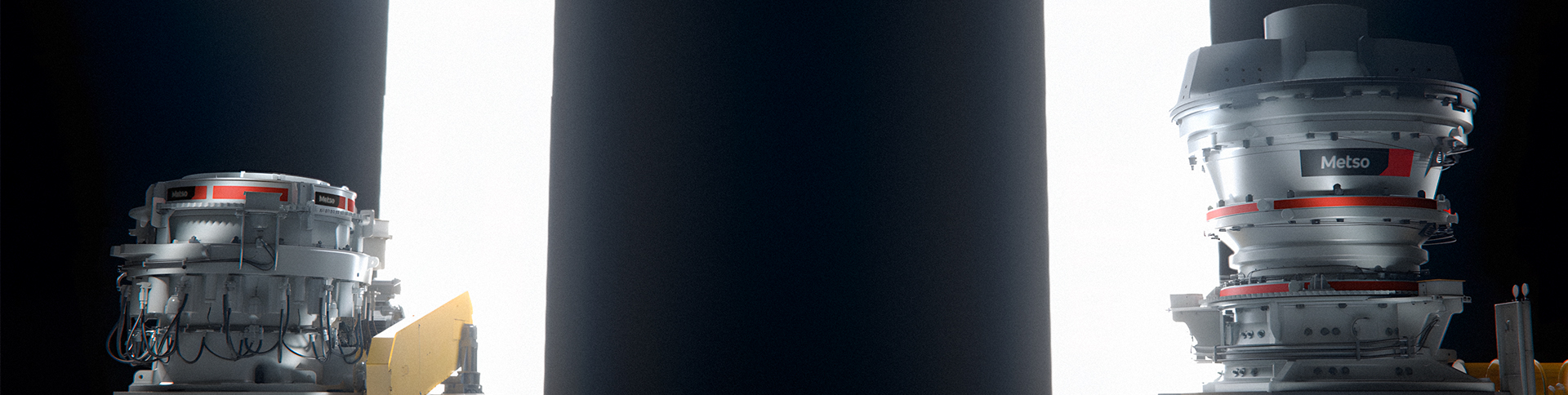

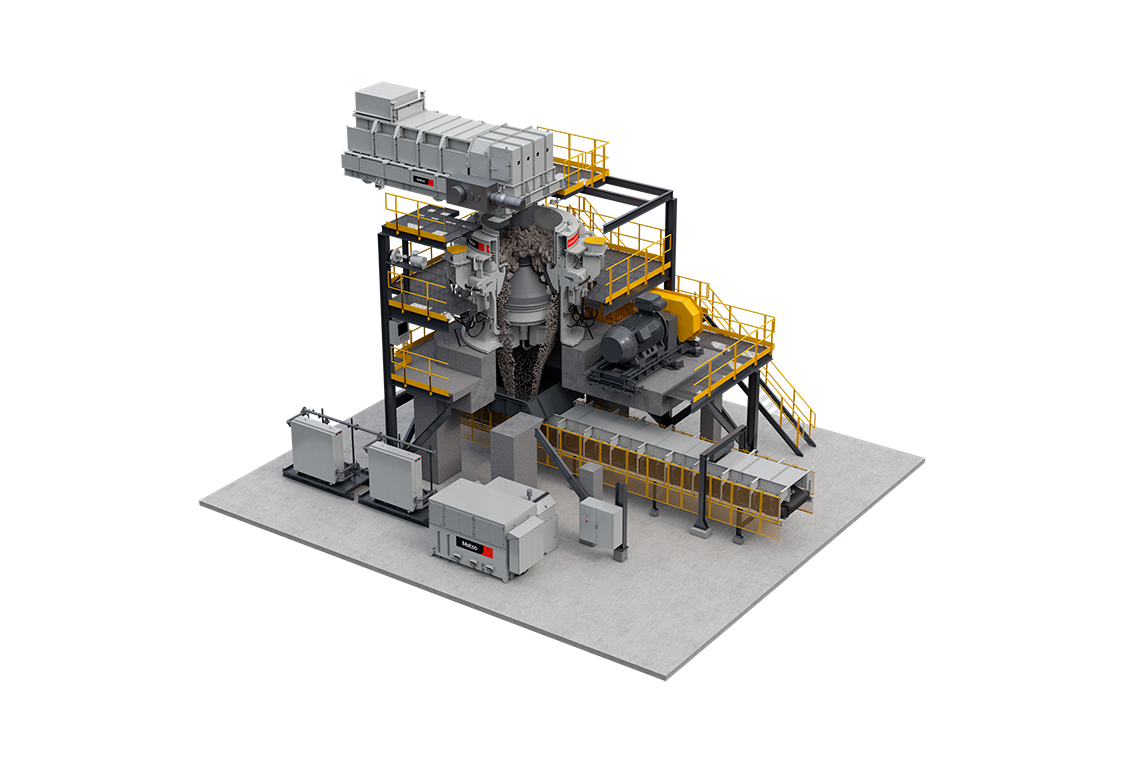

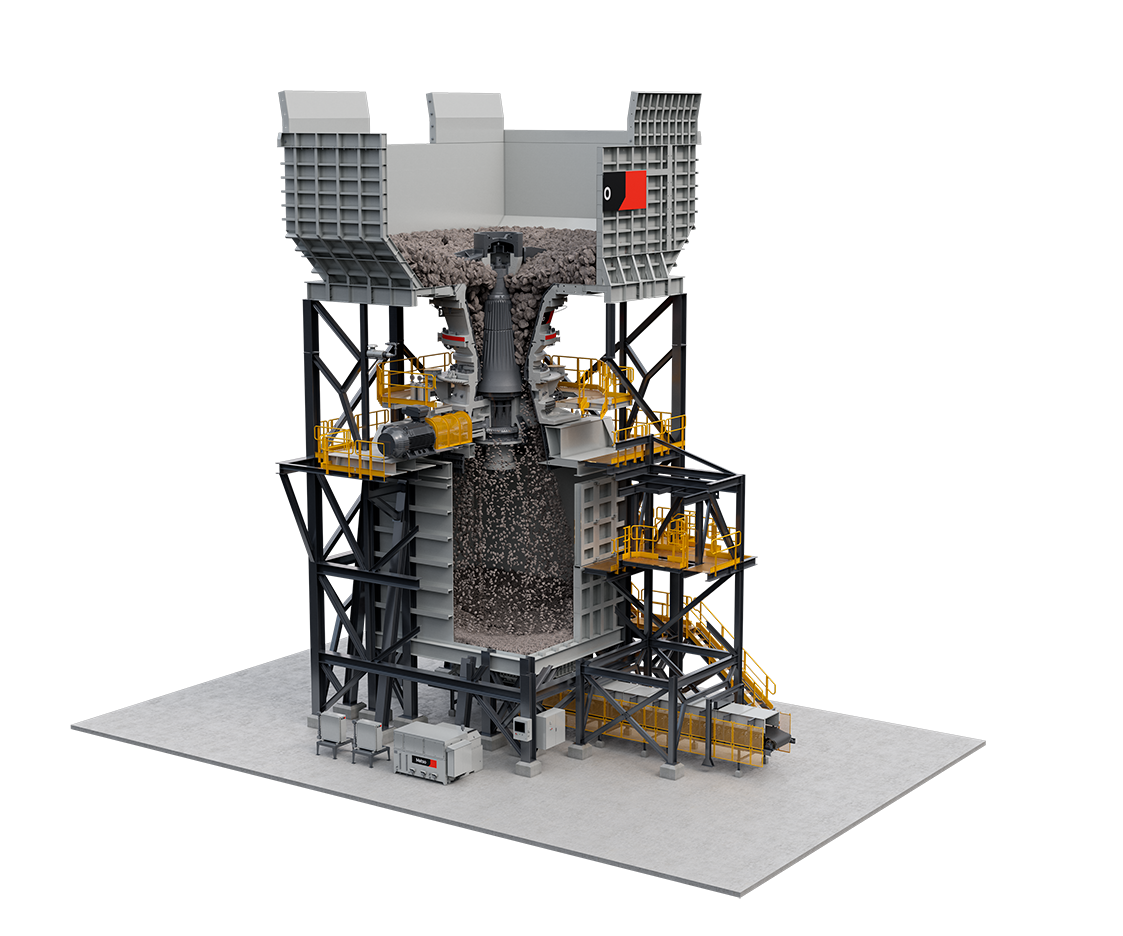

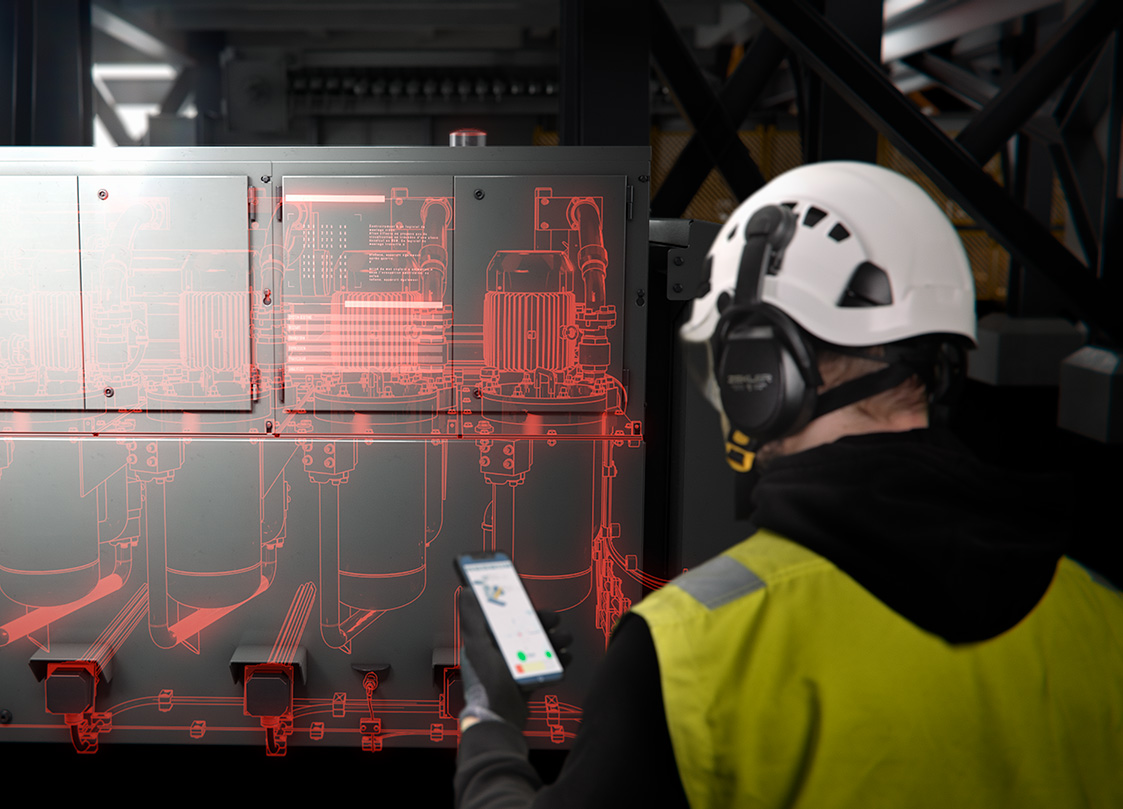

Optimize mining crushing processes with Mineral Crusher Pilot (MCP) automation

MCP automation creates more visibility, access and control of the minerals crushing process. Seamlessly integrate advanced digital technologies, empower operators, enhance safety and improve overall efficiency.