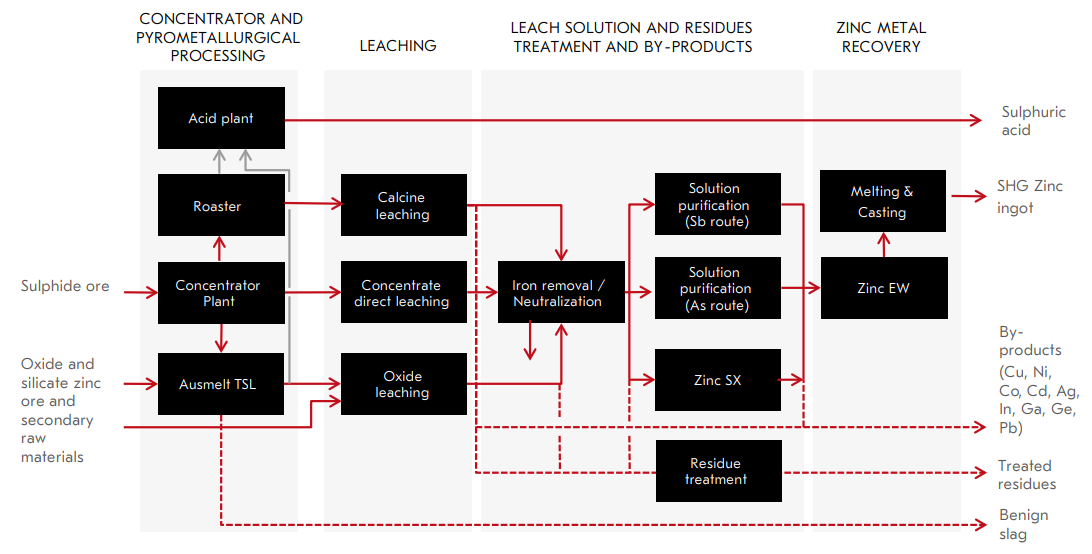

- Recovers zinc as SHG ingots and by-products such as Cu, Cd, Co, Ni, In, Ga, and Ge

- Adapts to different feed qualities and by-product recovery demands

- Scales to a wide range of production capacities

- Enables efficient oxidation at low cost with specially designed reactors for atmospheric leaching

- Boasts a low CAPEX as no roaster or acid plant is needed

Atmospheric direct leaching can easily be constructed to be standalone or combined with calcine leaching. The iron can be removed as jarosite or goethite. As a result of the precise control of iron oxidation and the acidity of the process solution, iron precipitation is carried out either during or after the leaching process, depending on the needs of the customer.