Digital solutions for Mining industry

Use our interactive tool to see how your challenges can be solved

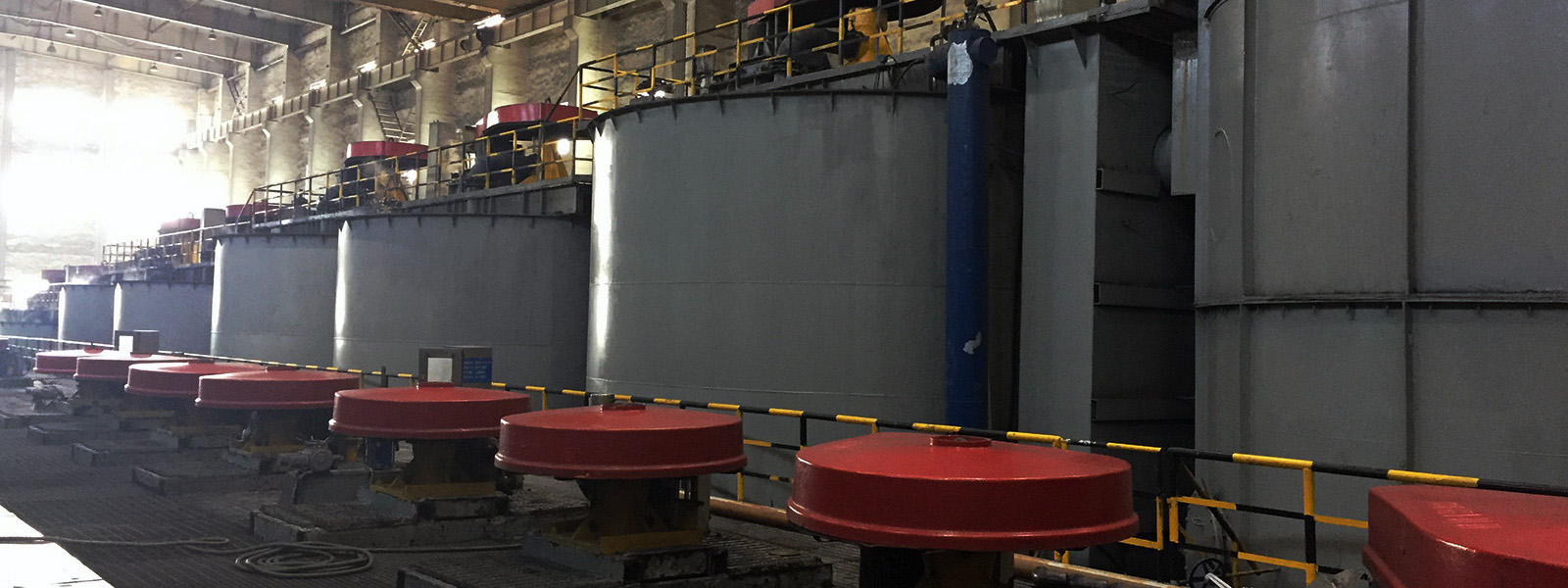

Supporting your operations, from plant design expertise to equipment, parts and services for every stage of your process.

Are you looking to increase production, reduce risks, lower operating costs and enhance environmental performance? Then you are in the right place.

From the design and supply of products for a greenfield plant, to the addition of a single machine for an existing production line, we are here to help.

Rely on OEM experts because not all parts are created equal. Spare and wear parts built to perform.

Helping you get the most out of your equipment and processes.

In the field of digitalization, Metso’s strengths lie in understanding our customers’ business and data, and utilizing that knowledge to analyze, automate and optimize their processes and performance. We strive to improve the key performance indicators of our equipment and services, and at the same time minimize their operational costs and environmental footprints.

Digitalization enables assets to become information sources that help reduce unscheduled downtime and maintenance costs. At the same time, they help increase asset utilization and extend equipment life.

Efficiency through continuous improvement remains a top priority, enabled by improving workforce safety, product productivity, quality and asset reliability.

With complex operations, it can be challenging to optimize your maintenance. You need to act proactively to prevent costly failures and ensure a safe work environment for your team. Advanced analytics, including predictive analytics, provide early warning notifications and diagnosis of equipment problems — days, weeks, or months in advance — combined with prescriptive actions to drive specific business outcomes.

Metso’s end-to-end solutions integrate accurate, live data from various sources and incorporate advanced analytics enriched with machine learning, artificial intelligence, and the scope and scale of cloud.

Utilizing more advanced technologies to meet the requirements for sustainable production also often requires highly skilled operators, skills that can be developed by our realistic training system, Virtual experience training simulators.

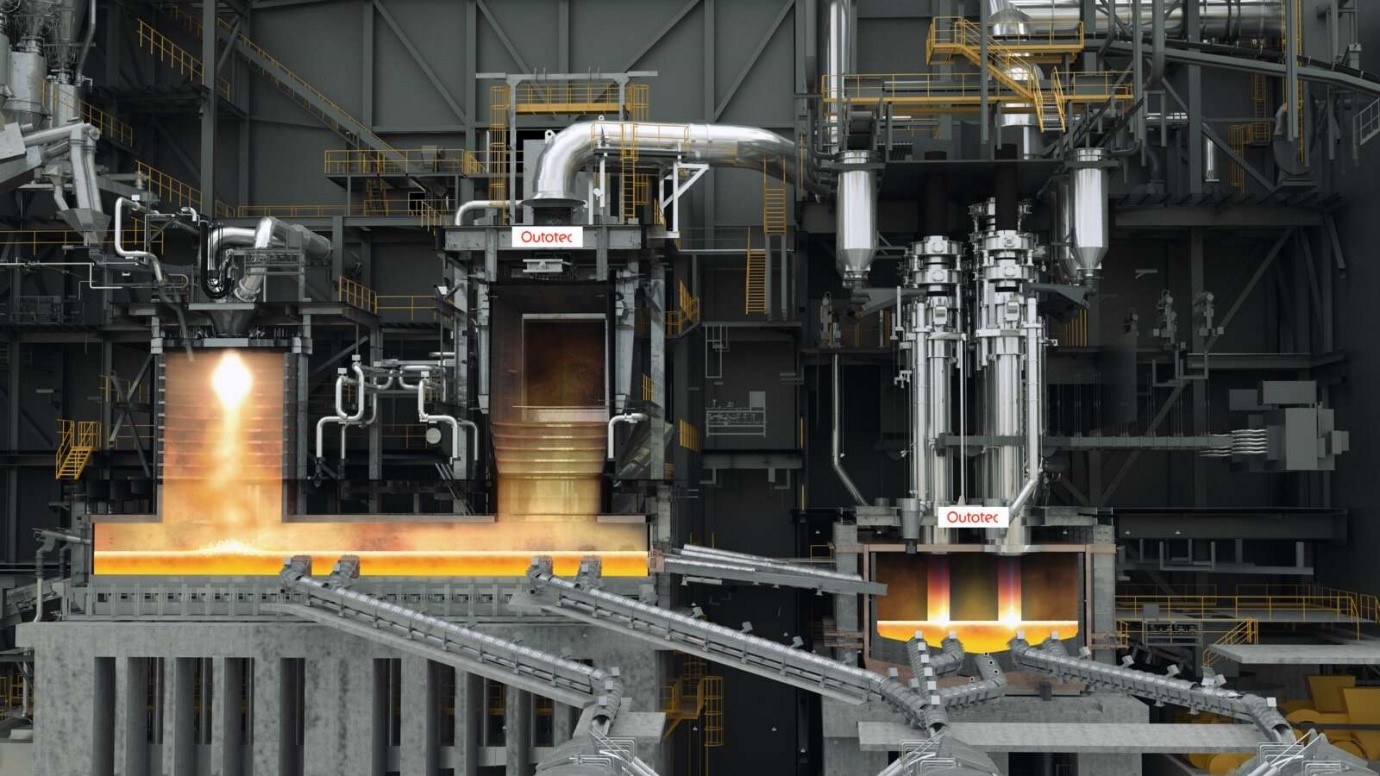

Automation and digital solutions provide a vital building block for the development of state-of-the art minerals processing circuits. Through our unique combination of technical and process know-how, digital capabilities, expertise to deliver and capability to monitor and support during operations we offer our customers a competitive advantage and peace of mind to operate over the entire life cycle of the plant.

Decades of crushing and screening experience acquired though working with customers around the world, coupled with an intimate knowledge of our equipment, means that operators can rely on us to provide solid recommendations that can help them to get more out of our equipment and their process.

Remote monitoring gives users the opportunity to take preventative actions and plan for potential shutdowns, even if they’re not on site.

Mobile and desktop applications allow users to remotely monitor equipment, eliminating the need to come into close contact with a running machine.

We combine technical and process know-how, digital technologies and the experience of delivering to the Metals industry. Thus our main product portfolio is in advanced process control tools (Advisors & Optimizers) and a suite of sensors and intelligent instruments to be used in the harsh conditions at plants. We also push for continuously adding more connectivity to our equipment to enable remote services and performance improvements of our customers' operations.