Visit resource center

Download operator's manuals, brochures, view 3D models and training videos for our conveying equipment.

Supporting your operations, from plant design expertise to equipment, parts and services for every stage of your process.

Are you looking to increase production, reduce risks, lower operating costs and enhance environmental performance? Then you are in the right place.

From the design and supply of products for a greenfield plant, to the addition of a single machine for an existing production line, we are here to help.

Rely on OEM experts because not all parts are created equal. Spare and wear parts built to perform.

Helping you get the most out of your equipment and processes.

The most complete product range on the market to maximize output and safety of your conveyor operations.

Dedicated to keeping your operation as productive and profitable as possible.

Durable conveyor parts designed for long component life.

Smart, simple design that makes parts efficient, robust and maintenance friendly.

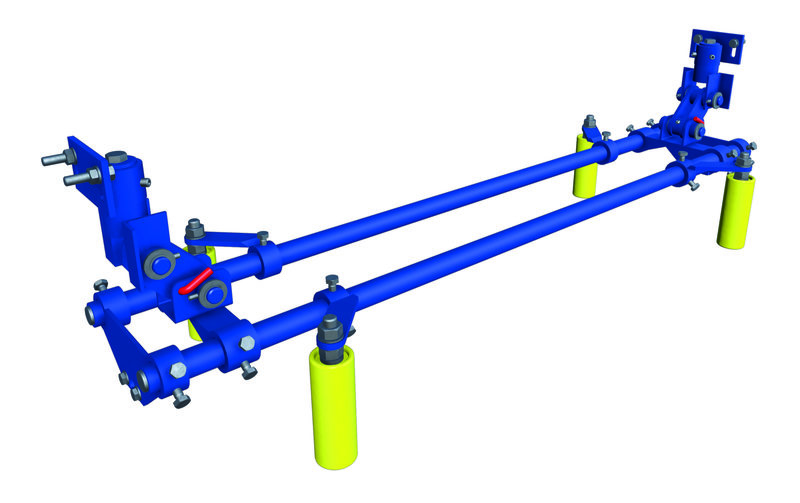

The greatest risk of belt misalignment is with reversible conveyors. Trellex RBC is an elegant solution to this problem. Mounted on top of the belt on the return side, its edge rollers detect the slightest deviation from the ideal belt path and guide it back on track automatically, regardless of which direction the belt is travelling.

Material properties

The basic construction is of powder-coated steel. Extra PU protection is available as an option to further extend the rollers’ wear life. High quality bushings are used in the pivot points to ensure optimal belt guidance. For easy maintenance, we also offer an optional central lubrication kit along with this product. The guide rollers are easy to install and replace, and the whole system can be adjusted to various belt widths and types.

Special features

Thanks to ultra-sensitive mistracking detection with fast response, Trellex RBC is a very smart way to minimize maintenance and spillage clean-up costs, and to prevent costly damage to your conveyor belt and frame. All of these factors work together to not only improve availability and your bottom line, but to reach your sustainability goals.

Construction material: Steel, S235JRG2

Surface treatment: Powder-coated blue RAL 5005

Installation

Belt speed: <2,5 m/s

Part No. | Description | Weight (kg) |

|---|---|---|

| 43272740 | TRELLEX RBC SET BW450-1200 | 53 |

| MM0361453 | TRELLEX RBC SET BW1400-1600 | 56 |

| 43272718 | TRELLEX SBC/RBC GUIDE ROLLER SLEEVE (OPTIONAL) | 0,4 |

| 43272710 | TRELLEX SBC/RBC GUIDE ROLLER (INCLUDED IN SET) | 2,3 |

| 43272730 | TRELLEX SBC/RBC LUBRICATING KIT (OPTIONAL - RECOMMENDED) |

Mounted on the return part of the belt, Trellex SBC and Trellex SBC-HD are simple, robust systems that centre the conveyor belt automatically as needed. They perform reliably even in the toughest working conditions, keeping your belt on track and protecting both belt and conveyor from harm. This means fewer costly stops for maintenance or adjustments, fewer staff interventions and hence, a safer, more productive work environment.

Material properties

The basic construction is of powder-coated steel. Extra polyurethane (PU) protection is available as an option to further extend the rollers’ wear life. Highquality bronze bushings are used in the pivot points to ensure optimal belt guidance. For easy maintenance, we also offer an optional central lubrication kit along with this product.

Special features

Ultra-sensitive mistracking detection and fast response make Trellex SBC and SBC-HD very high-performance belt guiding systems. The guide rollers are easy to install and replace, and the whole system can be adjusted to various belt widths and types.

Construction material: Steel, S235JRG2

Surface treatment: Powder-coated blue RAL 5005

Installation

SBC belt speed: < 2,5 m/s

SBC-HD belt speed: < 4 m/s

Part No. | Description | Weight (kg) |

|---|---|---|

| 43272700 | TRELLEX SBC SET BW450-1200 | 53 |

| MM0361444 | TRELLEX SBC SET BW1400-1600 | 56 |

| MM0393914 | TRELLEX SBC-HD SET BW450-2400 WITHOUT SQUARE SHAFTS | 66 |

| 43272760 | TRELLEX SBC-HD SET BW450-2400 WITH SQUARE SHAFTS | 169 |

| 43272718 | TRELLEX SBC/RBC GUIDE ROLLER SLEEVE (OPTIONAL) | 0,4 |

| 43272710 | TRELLEX SBC/RBC GUIDE ROLLER (INCLUDED IN SET) | 2,3 |

| 43272778 | TRELLEX SBC-HD GUIDE ROLLER SLEEVE (OPTIONAL) | 0,9 |

| 43272770 | TRELLEX SBC-HD GUIDE ROLLER (INCLUDED IN SET) | 3 |

| 43272730 | TRELLEX SBC/RBC LUBRICATING KIT (OPTIONAL - RECOMMENDED) |