Visit resource center

Download operator's manuals, brochures, view 3D models and training videos for our conveying equipment.

Supporting your operations, from plant design expertise to equipment, parts and services for every stage of your process.

Are you looking to increase production, reduce risks, lower operating costs and enhance environmental performance? Then you are in the right place.

From the design and supply of products for a greenfield plant, to the addition of a single machine for an existing production line, we are here to help.

Rely on OEM experts because not all parts are created equal. Spare and wear parts built to perform.

Helping you get the most out of your equipment and processes.

The most complete product range on the market to maximize output and safety of your conveyor operations.

Dedicated to keeping your operation as productive and profitable as possible.

Durable conveyor parts designed for long component life.

Smart, simple design that makes parts efficient, robust and maintenance friendly.

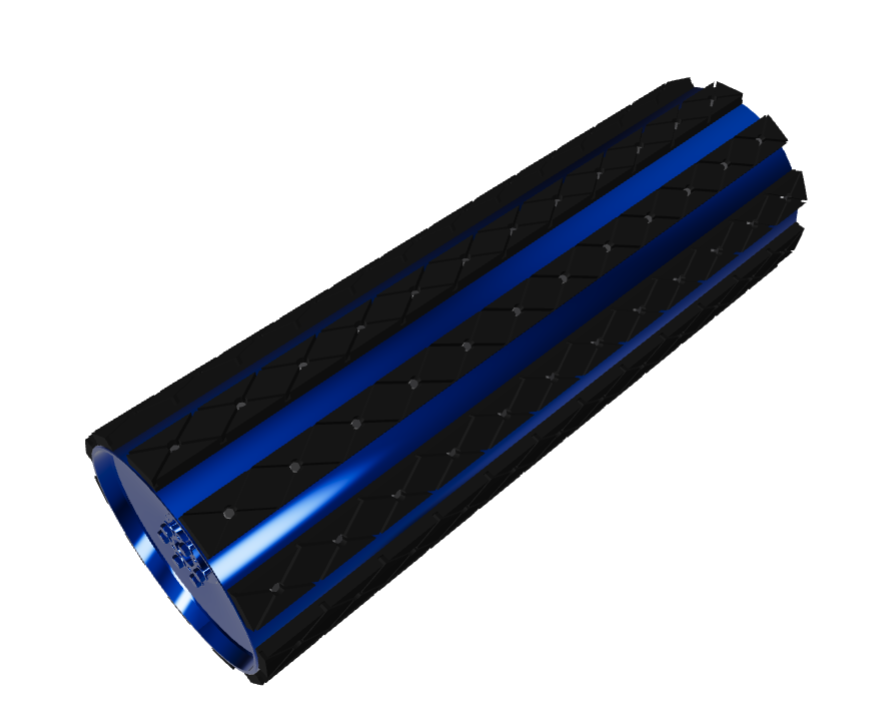

Metso’s Trellex pulley bar is used in applications that require an easy installation and operation. Benefits include the application and removal of the lagging without removing the drum or belt from the conveyor system.

Trellex pulley bar is made of hardwearing rubber and molded to an aluminium profile, this product has the perfect combination of elasticity and rigidity. This gives a superior ability to handle internal wear. The pattern also naturally eliminates water from the surface of the lagging as the pulley rotates.

Installation: Medium to heavy duty applications

Bolted

Improved belt tracking

Reduces slippage between belt & pulley

Suitable for light, medium & heavy applications

Suits any pulley size

Easy to install – without removing belt or pulley

Reduced application time

Material: Wear Rubber Trellex T60 ShoreA

Wear side:Diamond-pattern

Installation: Bolted to pulley surface

Material: Wear Rubber Trellex T60 ShoreA

Wear side:Diamond-pattern

Installation: Bolted to pulley surface

| Rubber properties | |

| Hardness | 60 ± 5° Shore A |

| Tensile strength | > 20 N/mm2 (MPa) |

| Elongation at break | > 450 % |

| Heat Ageing | (Property change after 168 hours in 70°C) |

| Hardness | +8° Shore A |

| Tensile strength | Max -25 % |

| Elongation | Max -40 % |

22x70x1365 mm

| PART NO. | DESCRIPTION |

| 958065 | TRELLEX PULLEY BAR 22X70X1365 |

| 430958065 | TRELLEX PULLEY BAR 22X70X1365 STANDARD W/ SCREWS |

| 1762104 | TRELLEX CA-COMP M6SF-TT DIN 75000DD M8X25 |

Storage room for lagging must be cool, dry and kept clean.

Protect the lagging from dust, water etc. with suitable coverings.

Avoid storage places near sources of ozone generating equipment.

UV light can damage the product – protect product against direct sunlight and strong artificial light.

Do NOT store outside.

Do NOT store together with fuels, lubricants, acids, disinfectants, solvents or other chemicals.

Allow 24 hours before use when lagging is removed from cold storage.

Shelf life for lagging: 3 years.

(Stored covered out of sunlight UV and away from ozone generating equipment)

Use this formula to determine if pulley bars can be used:

F = P

h x D x B

P = power (kW)

h = belt speed (m/s)

D = pulley diameter (m)

B = pulley width (m)

F should not exceed 130.

Shape is designed to suit all pulley diameters:

| Number of bars | ||||

| Pulley diameter (mm) | Belt speed <1.5m/s | Belt speed >1.5m/s | ||

| Ø | Alt. 1 | Alt. 1 | Alt. 2 | |

| 150 | 7 | 7 | 7 | |

| 200 | 9 | 9 | 9 | |

| 300 | 11 | 11 | 12 | |

| 400 | 12 | 14 | 16 | |

| 500 | 15 | 17 | 21 | |

| 600 | 18 | 20 | 25 | |

| 630 | 19 | 21 | 26 | |

| 700 | 21 | 23 | 29 | |

| 800 | 24 | 26 | 33 | |

| 900 | 27 | 30 | 38 | |

| 1000 | 29 | 33 | 42 | |

| 1100 | 32 | 36 | 46 | |

| 1200 | 34 | 40 | 50 | |

| 1250 | 36 | 41 | 53 | |

| 1300 | 37 | 43 | 55 | |

| 1400 | 40 | 46 | 59 | |

|

Use this formula to determine if pulley bars can be used: F = P

| ||||

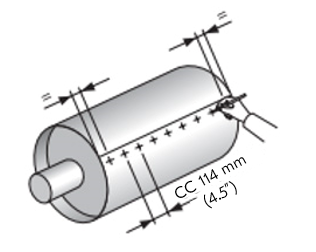

Hole centers on the drum, CC = 114 mm (4.5"):

Hole diameter 7.4 mm (0.29") for M8 self tapping screws:

Recommended tightening torque 25 Nm (19 lbf/ft):

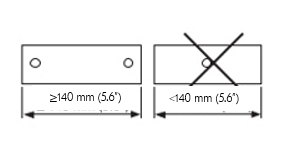

Never install a piece that is shorter than 140 mm (5.5") and never use fewer than two screws:

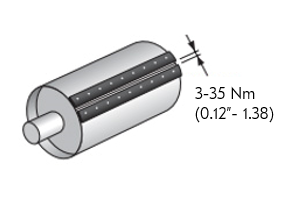

Standard distance between Pulleybars is 35 mm. At belt speed >1.5m/s the distance between the pulley bars can be as little as 3 mm:

To avoid high noise level at belt speed >1.5 m/s we recommend installation as alternative 2

We collect and process your data on this site to better understand how it is used. You can give your consent to all or selected purposes or decline the non-essential ones. Essential cookies, which are necessary for the basic website functionality such as page navigation, cannot be declined. Without these cookies, the website would not function properly. For more details, please refer to our Privacy Notice.

Privacy Notice