and easiness

-

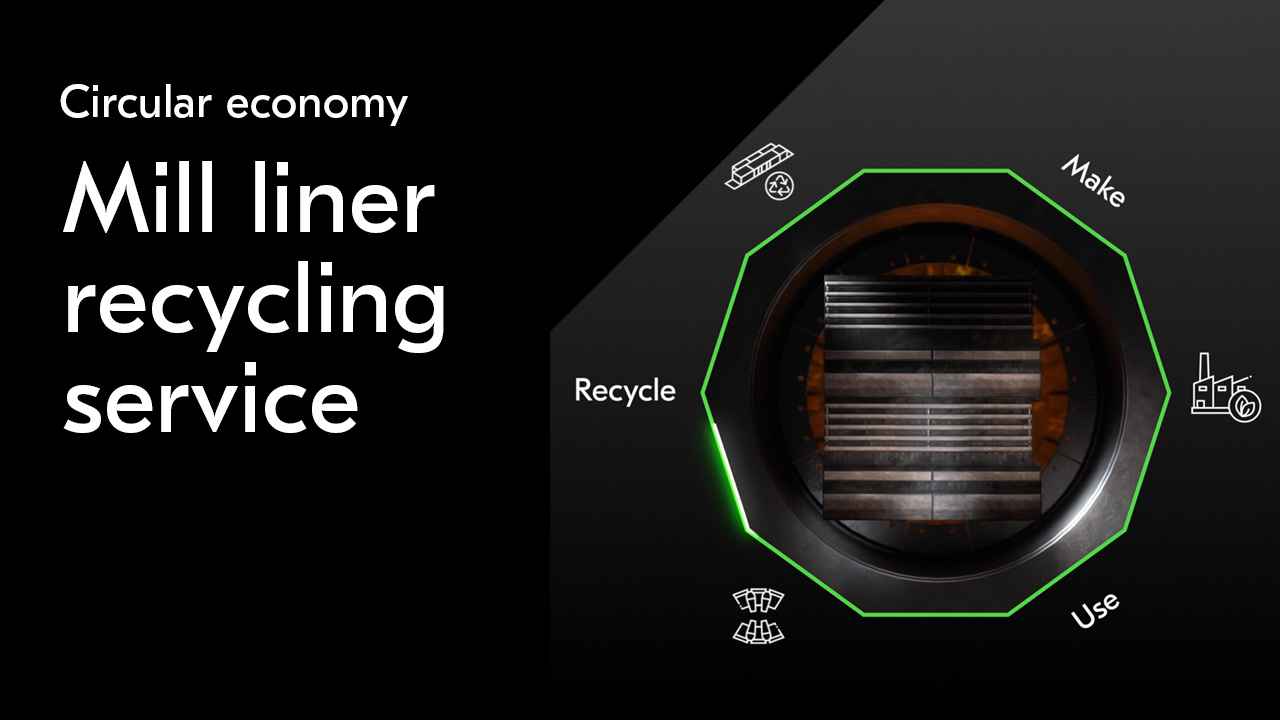

Worn liners are collected on site

-

Liners are transported to the Metso facility

-

Liner components are separated in the new separation line

-

Valuable materials (rubber and steel components) are either reused or recycled as raw material for new liners

-

Liners can be recycled again after use

After over a decade of intensive development work and pilots, we are pleased to introduce our latest circularity innovation, a unique separation line to process worn mill liners. The modular and container-based separation line enables safe and efficient separation of different rubber and metal liner components. They come out of the process unharmed and can be either reused or recycled in the most optimal way.

The recycling service using the new separation line is available as a part of a mill lining service contract. Partnering with us gives you thorough audits, liner design, technical support, wear follow-up and constant liner improvements. Best of all, the recycling service facilitates an easy way to dispose of worn liners in an environmentally efficient way.