Safer and faster wear readings

Thorough and detailed insights

Long-lasting liners optimized for your current conditions reduce CO2 emissions

Accurate maintenance planning

Understand how a mill liner wears

Liner Wear Monitoring

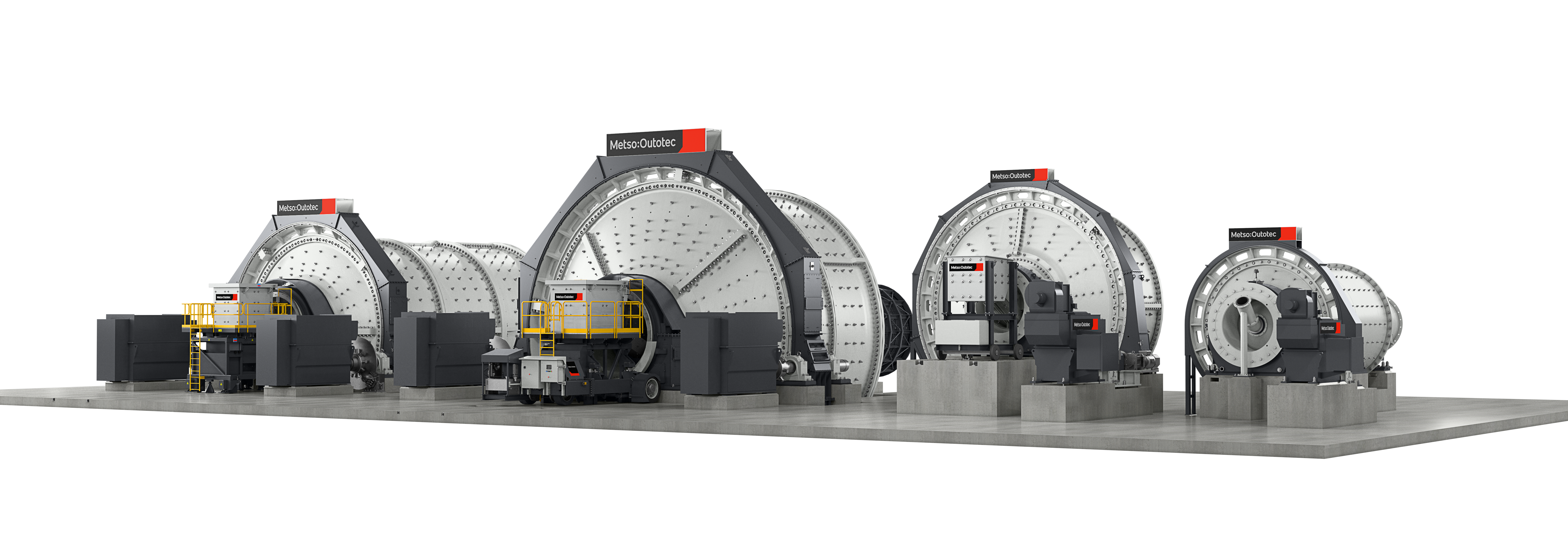

Unique in the industry, Metso MillMapper™ liner wear monitoring allows your maintenance and operational personnel to extend liner life cycles, optimize liner design, prevent liner failures, optimize throughput, and improve the performance of your mill.

Benefits:

- Improves safety

- Minimizes inspection shutdown times

- Captures wear data on the entire mill

- Offers reliable reline forecasting

- Optimizes liner designs

- Defines metallurgical parameters

- Improves identification of liner abnormalities to significantly reduce unforeseen liner failures

- Enter your mill in a 3D environment

Read more about MillMapper here.

Instead of using the general discrete element modeling (DEM) software available on the market, we have developed our own set of simulation software that uses algorithms created based on our vast grinding process know-how.

The unique wear-progression model predicts the performance of the lining extremely accurately and can be calibrated using wear-monitoring data to further optimize the liner design. It is the market’s most advanced software for comparing different lining alternatives and calculating total costs over lining life cycles.

Read more about simulation tools here

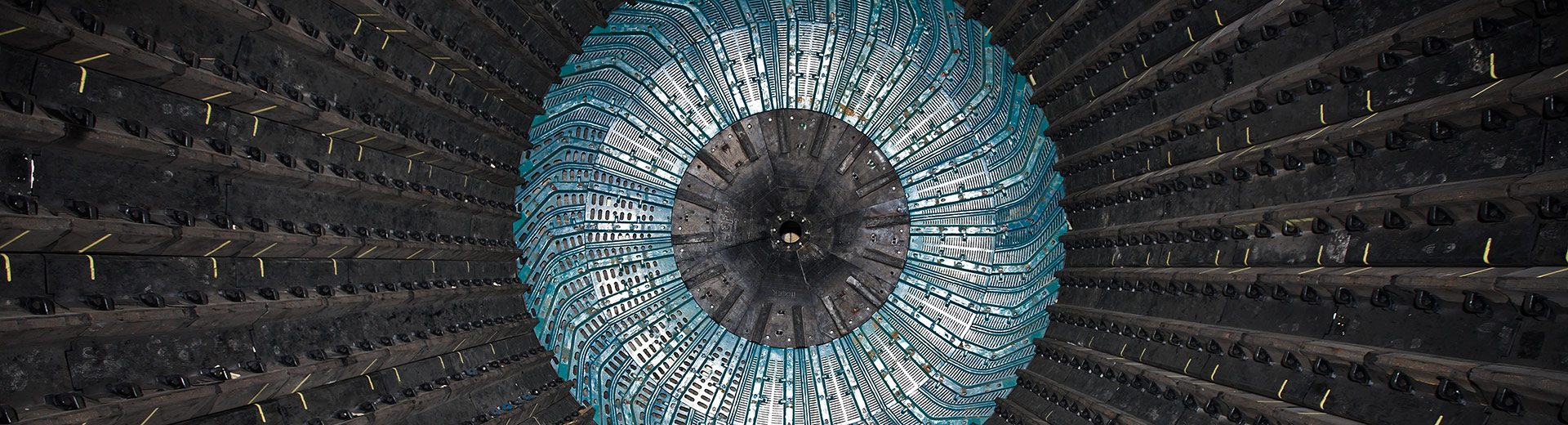

The new patented Virtual Inspection platform brings the benefits of 3D-scanning to a new level. It enables viewing of your scanned mill linings in virtual reality and offers an efficient and safe environment for technical discussions.

- The users enter a 360° environment where they can move about freely in a 3D virtual setting and interact with the mill lining scan to analyze it.

- You get to see your own individual linings scans and the tool offers ways to display and address problem areas, improvements, and new concepts remotely.