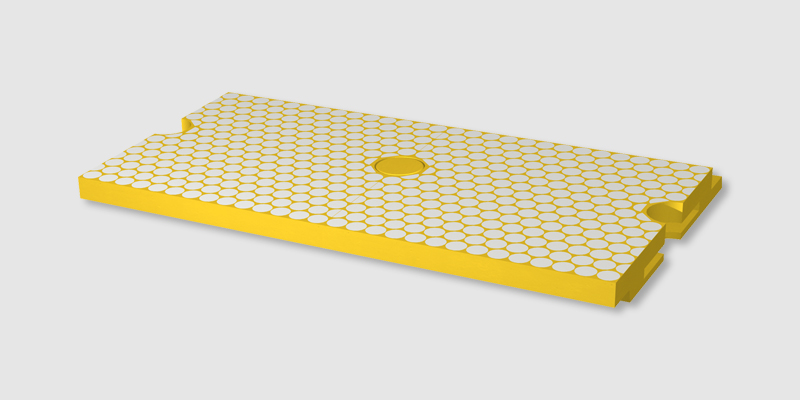

Ceramic wear plates maximize the lifetime of your equipment, and increase production capacity in both wet and dry applications.

Improve poor material flow caused by narrow sectors in the process. Such spots can be real bottlenecks and create a lot of additional work and unplanned downtime.

All ceramic wear products reduce noise and contribute to a better work environment.

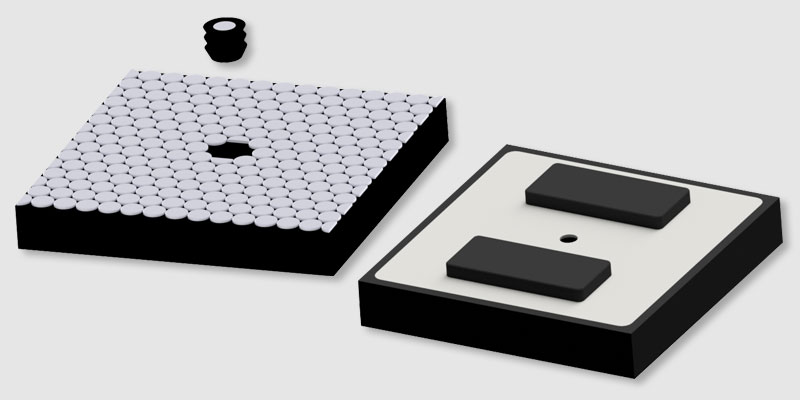

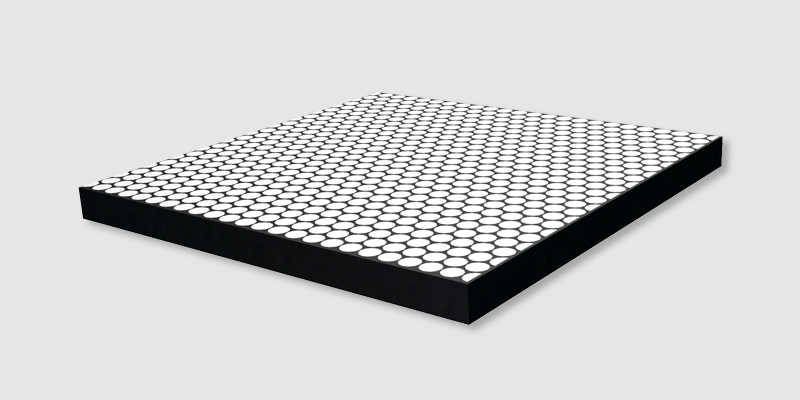

Modern wear protection system which reduces impacts and improves health and safety without increasing costs or sacrificing operational efficiency. The modular system can handle particle sizes up to 200 mm (8”) and resists pH values 4-9 and all water types, and most oils and chemicals in moderate/small concentrations.

Hard ceramic surfaces provide unsurpassable wear resistance while the elasticity of the rubber absorbs the impact of blows. Excellent wear resistance in applications with sliding wear and high material speeds.

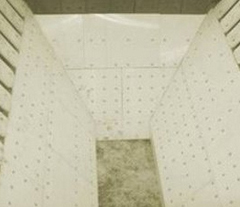

Tough modular liner system and the ultimate choice for situations where equipment can only be accessed from the inside. Available in a range of material options to suit the application, including cast metallic options, rubber and ceramic products.