Prolong the lifetime of your equipment, improve sustainability and safety.

Improve poor material flow caused by narrow sectors in the process. Such spots can be real bottlenecks and create a lot of additional work and unplanned downtime.

Our rubber wear products reduce noise and vibration, and thereby contribute to a better work environment.

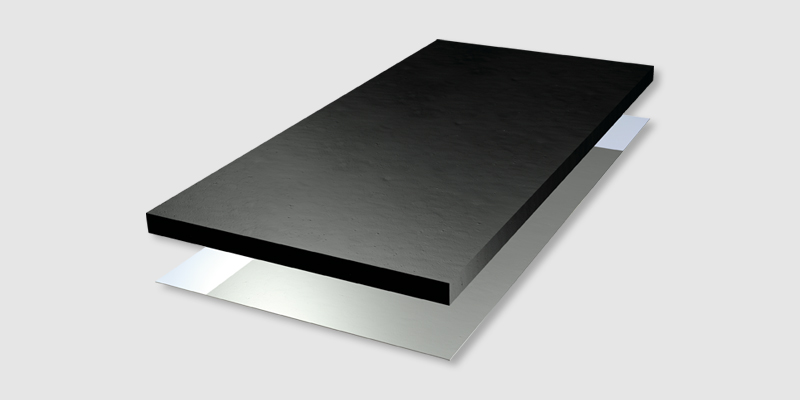

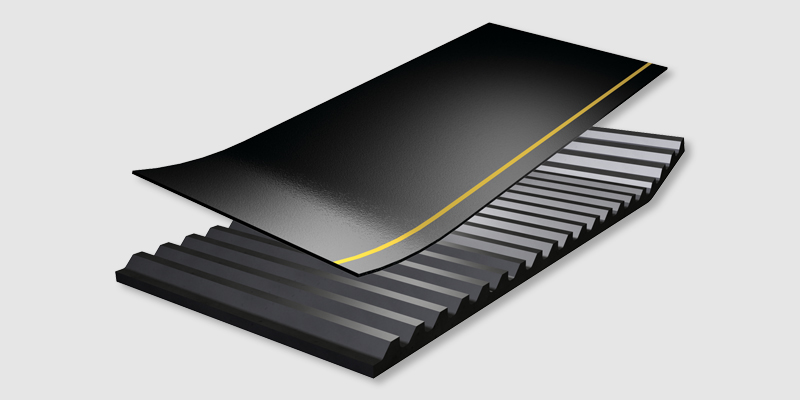

Manufactured from T60 wear rubber and with hot-vulcanized steel reinforcement, provide first class wear protection in such tough applications as truck beds, primary chutes, etc. and for secondary applications such as chutes, feeders, channels, silos and other applications that are subject to wear and noise.

Manufactured from T60 wear rubber and include hot vulcanized aluminum fixing profiles, provide excellent wear resistance in applications with both impact and sliding wear. The vulcanized aluminum profiles allow for fewer fixing points than steel-reinforced wear plates.

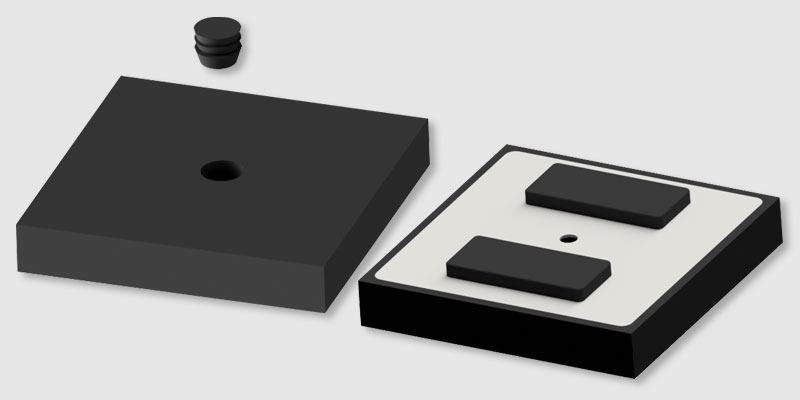

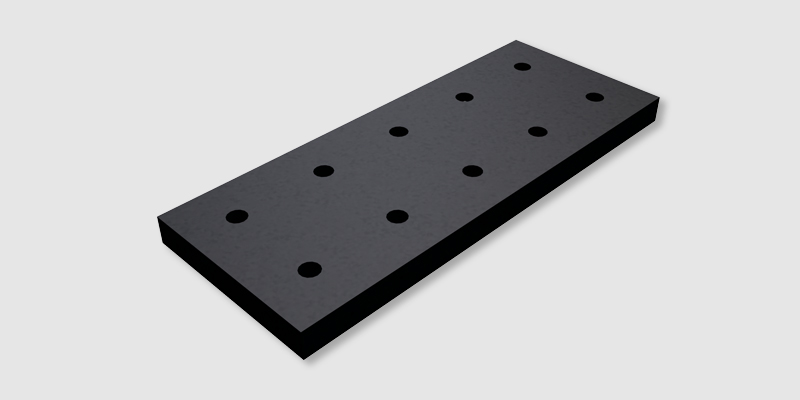

These plates are manufactured from T60 wear rubber with molded holes for fixing. The holes are reinforced with fixed hot vulcanized internal steel washers. Provide excellent wear resistance in applications with both impact and sliding wear. The wear plates are bendable and easy to cut.

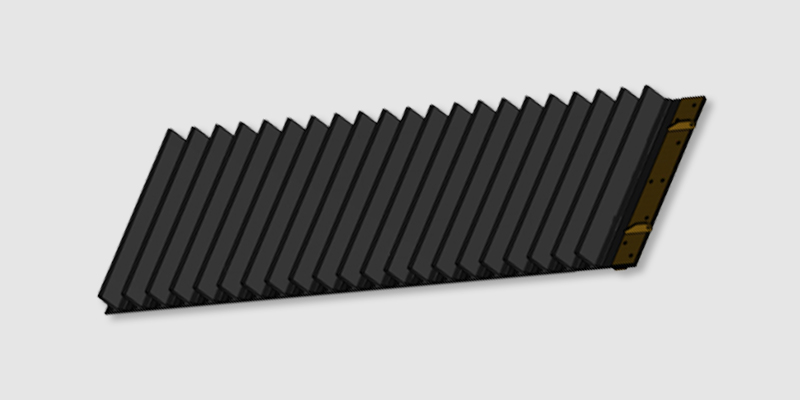

Wear bars manufactured from T60 wear rubber and include hot-vulcanized aluminum fixing profile. Excellent wear resistance in applications with both impact and sliding wear. The embedded aluminum profile allow for fewer fixing points than steel-reinforced wear plates.

Shows excellent wear resistance in lighter and medium applications. The reinforcement makes it possible to construct self-supporting channels and chutes with simple supports of angle iron and flat iron. Provides excellent wear protection for chutes, channels, bins and other applications that are subject to wear and noise.

Modern environmentally friendly wear protection system which reduces impacts and improves health and safety without increasing costs or sacrificing operational efficiency. Designed for simplicity of installation and minimum downtime by using patented fastening system and are easily cut with a knife or Alu-Cut machine.

Rubber curtains designed to fit all types of chutes and hoppers processing wet fines. Self-cleaning properties significantly reduce the build-up of fines and sticky materials that cause blockages.

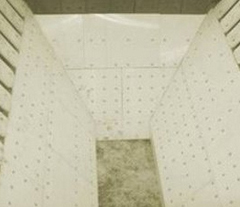

Tough modular liner system and the ultimate choice for situations where equipment can only be accessed from the inside. Available in a range of material options to suit the application, including cast metallic options, rubber and ceramic products.