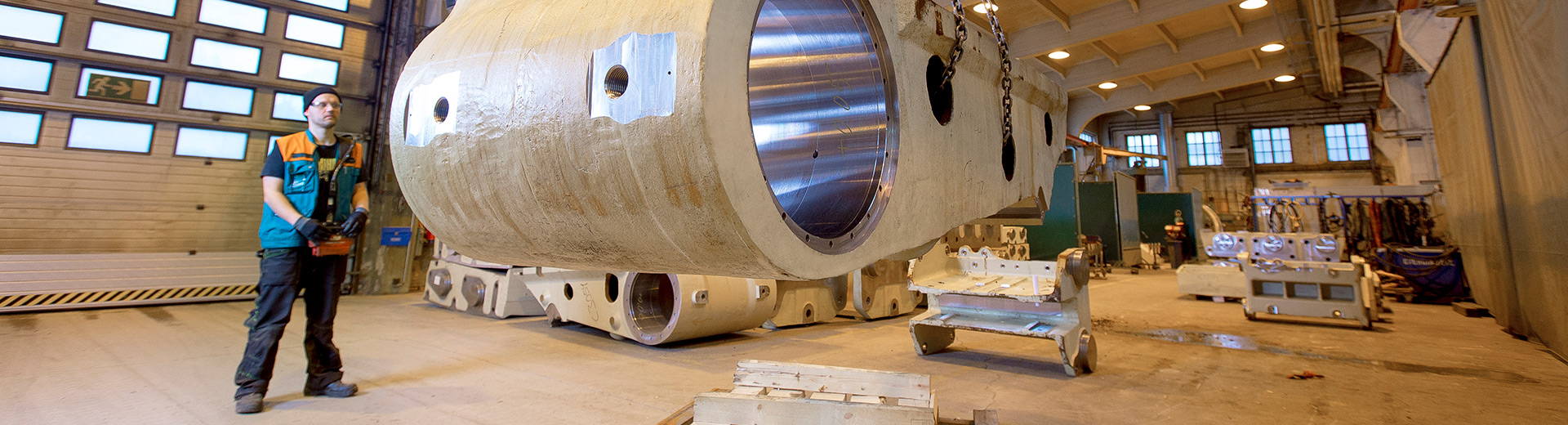

Do you want to see this on your crushers?

Avoid undetected issues

Crusher inspections as Your Road to Trouble-free Operations

Higher crusher availablity

Reduced maintenance costs

Optimized end product quality

Preventive maintenance and proactive repairs

Regular inspections improve efficiency

- A daily check of the condition and cleanliness of the hydraulic power units, hydraulic oil tank levels, oil temperatures, cooling fans and oil pressure levels among others

- Overall noise of the crusher while operating

- Bearing temperatures, crusher vibrations, feed distribution, feed level and electric power draw

* Refer to the manual you’ve received with your equipment to find the complete list

Thorough, specialized inspections by Metso experts

Up to two hours with the equipment operating and about 4-6 hours shutdown depending on whether it’s a stationary or mobile operation to review the general condition of the equipment. This includes a review of key wear components and additional verification of critical spare components. No disassembly of the equipment is required.

Whenever wears are replaced on any type of crusher, a more in-depth inspection can be performed not only on the bowls/concaves and mantle, but also on other components such as bushings, eccentrics, MPS, and pitmans depending on the crusher being inspected. All points covered in the 1000-hr inspection are also done.

One or two-day disassembly inspection including assessment of the condition of all major components with detailed measurements. Typically, wear part change-outs, major spare parts and component replacement or an equipment upgrade can be scheduled at the same time.

Expert report with recommendations

What can you learn from the IC connected to your machine?

Many important and crucial parameters can be checked from the IC connected to your crushers. Keeping a constant eye on those can help you anticipate and prevent problems before they really happen! See trends, alarms, parameter changes and live operating conditions (remotely with IC and Metrics). Proper diagnosis can be a (pre-cursor / indicator / point out) to future repairs (or is a best practice, pro-active maintenance program)

Discover how the IC automation on crushers can help you get the most of your crushing process, from this webinar.