Reaching your sustainability targets?

Find out how our filtration services help to achieve your sustainability targets

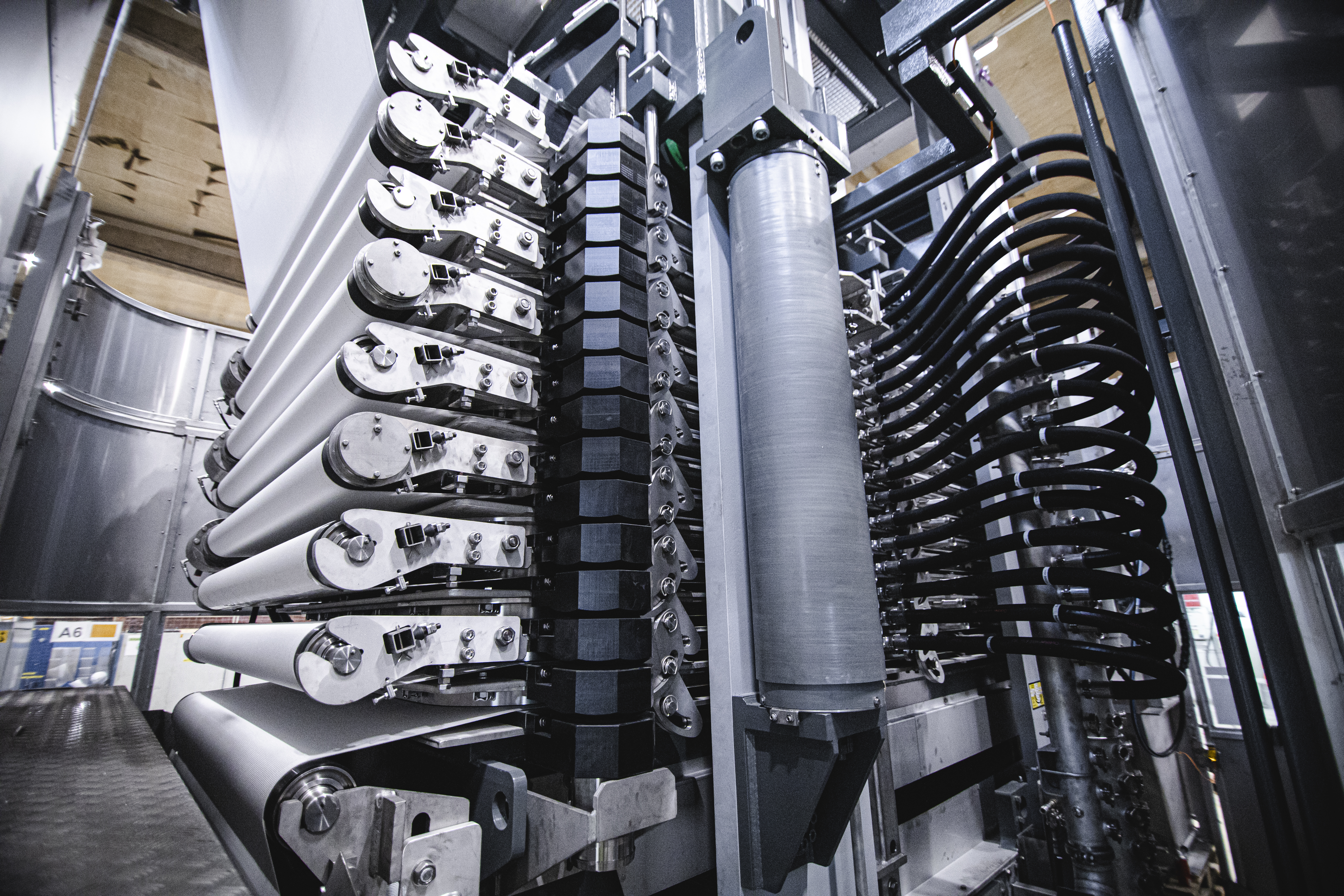

Detect issues before they cause equipment failure

Efficient planning and maintenance strategy & create KPIs

Optimize performance & processes

Conduct repairs & maintenance before failures & downtime occur

A quick way to understand your filters overall condition for peace of mind

The downtime required is 1/2 shift, total inspection time 1 shift done 1-2 times per year. The inspection is performed during operation with quick shutdown stops.

* Components and tasks may vary depending on the type of filter

Maximized filter availability through a more detailed inspection with additional adjustments and services

The downtime required is 1 shift, total inspection time takes 2 shifts, conducted once a year. Full mechanical inspection with filter operating and shutdown. Approximate inspection time allocated to 1 shift with filter running and 1 shift with filter shutdown. Includes the Filter Visuals and Vitals inspection as well as:

* Components and tasks may vary depending on the type of filter

Maximized filter performance and equipment longevity

The downtime required is 3-5 shifts, conducted once every 2-3 years. Full visual, vitals, and mechanical inspections. Additional services are:

* Components and tasks may vary depending on the type of filter