To maintain long term profitability and mitigate risk it is important to understand how variability in the deposit will affect the operation. Achieving this goal requires an understanding of how the process behaves for different ore types and the distribution of ore types throughout the ore body.

Integrating the disciplines of geology, mining and metallurgy, our geometallurgical modelling solution helps you to develop proactive operating strategies from mine to plant as a function of ore variability.

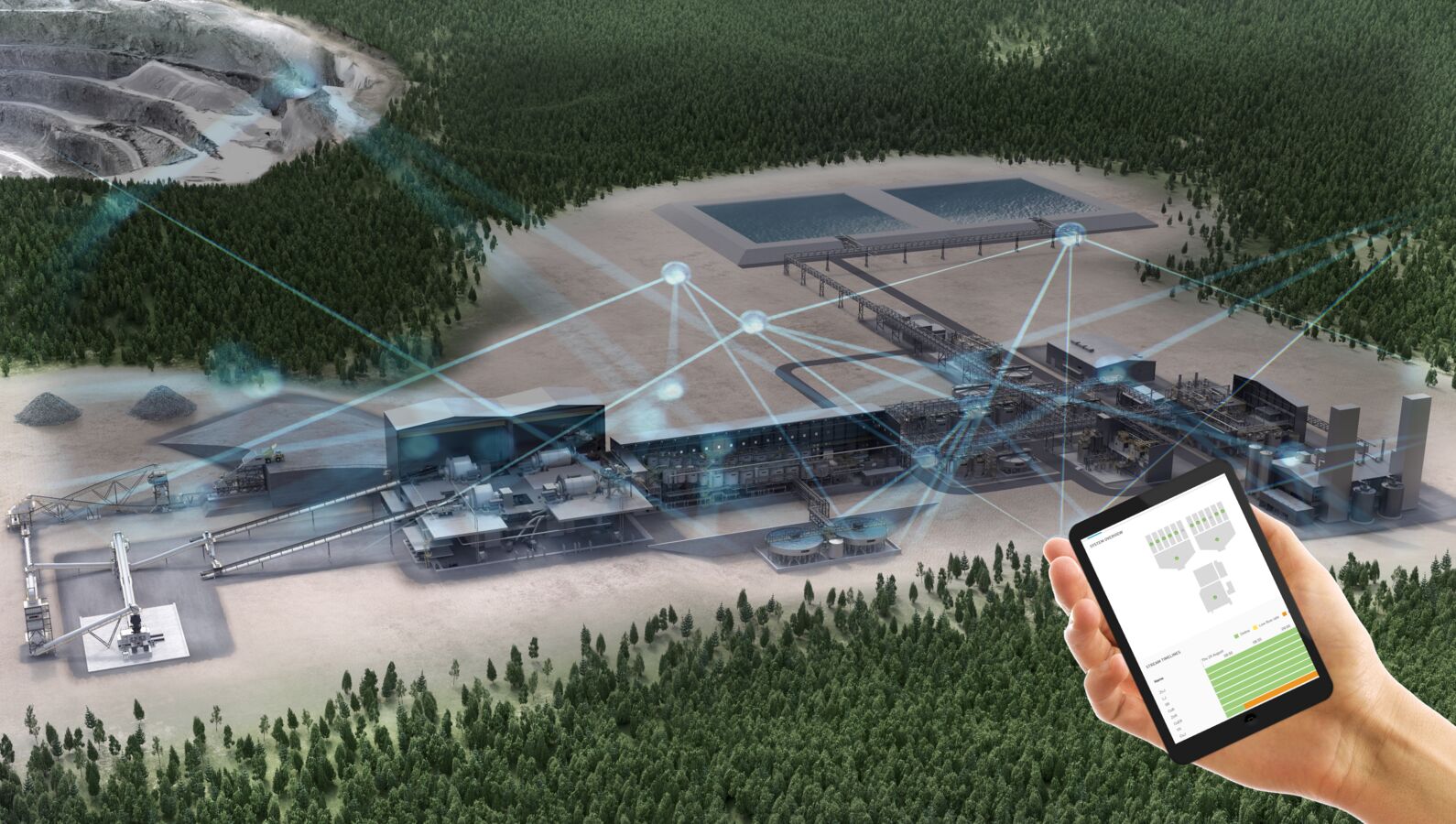

Effective geometallurgical modelling requires good quality ore characterization data and knowledge of how these properties affect process performance. At the heart of our service, GeoMetso™ provides an automated link between the ore source and plant performance. As a result, the predictive models and geotechnical block model are automatically updated in real-time.

Parcels of ore are tracked continuously from the mine into the process using SmartTag™ technology and the associated plant performance data is collected from the control system. This data is automatically compared with model predictions and updated in the block model in real-time. As a result, the block model is continuously populated and refined with actual plant data, eliminating the need for further expensive ore characterization tests. Additionally, it improves the accuracy and predictive abilities of geometallurgical modelling.