Life Cycle Services for mining

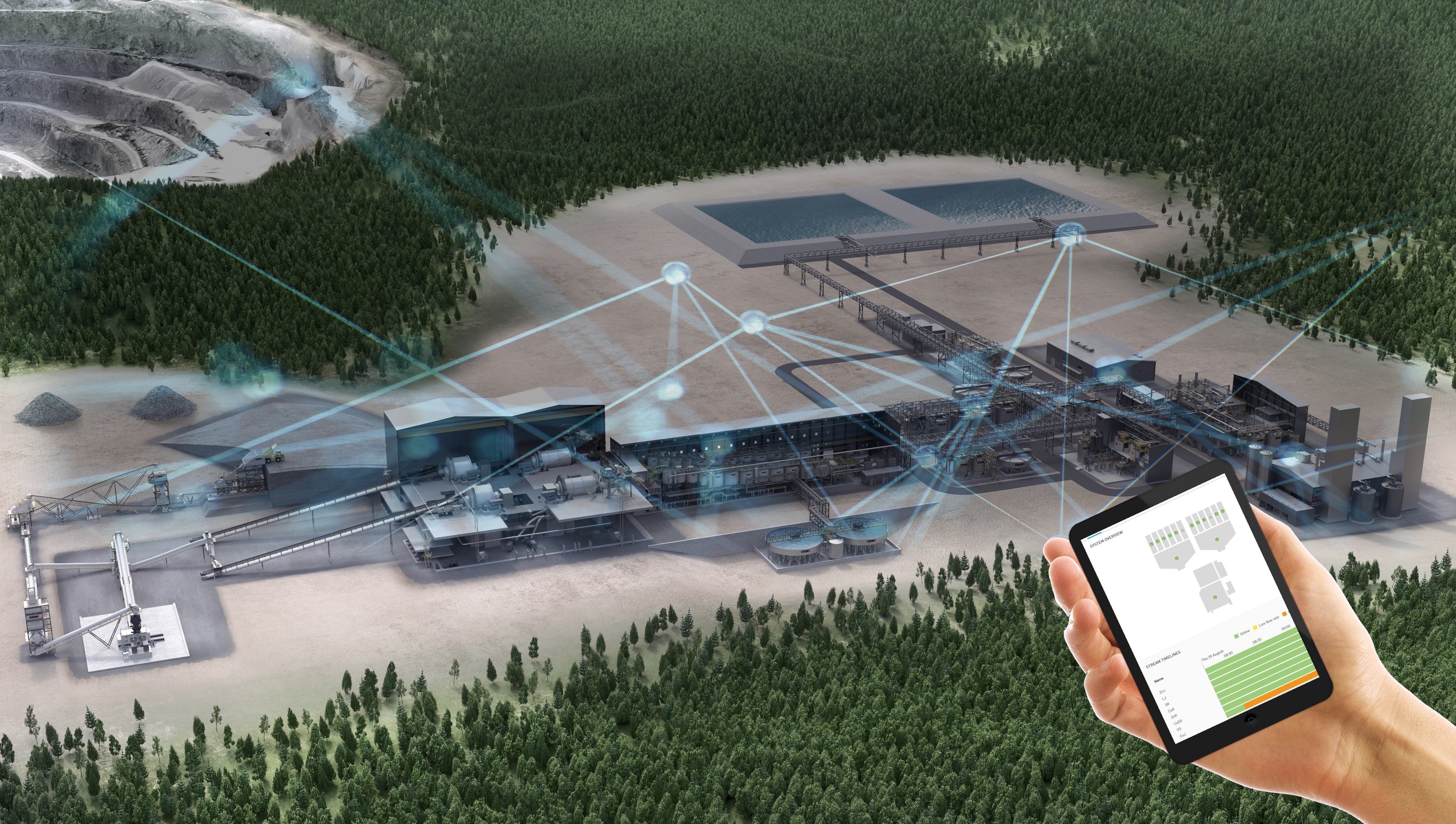

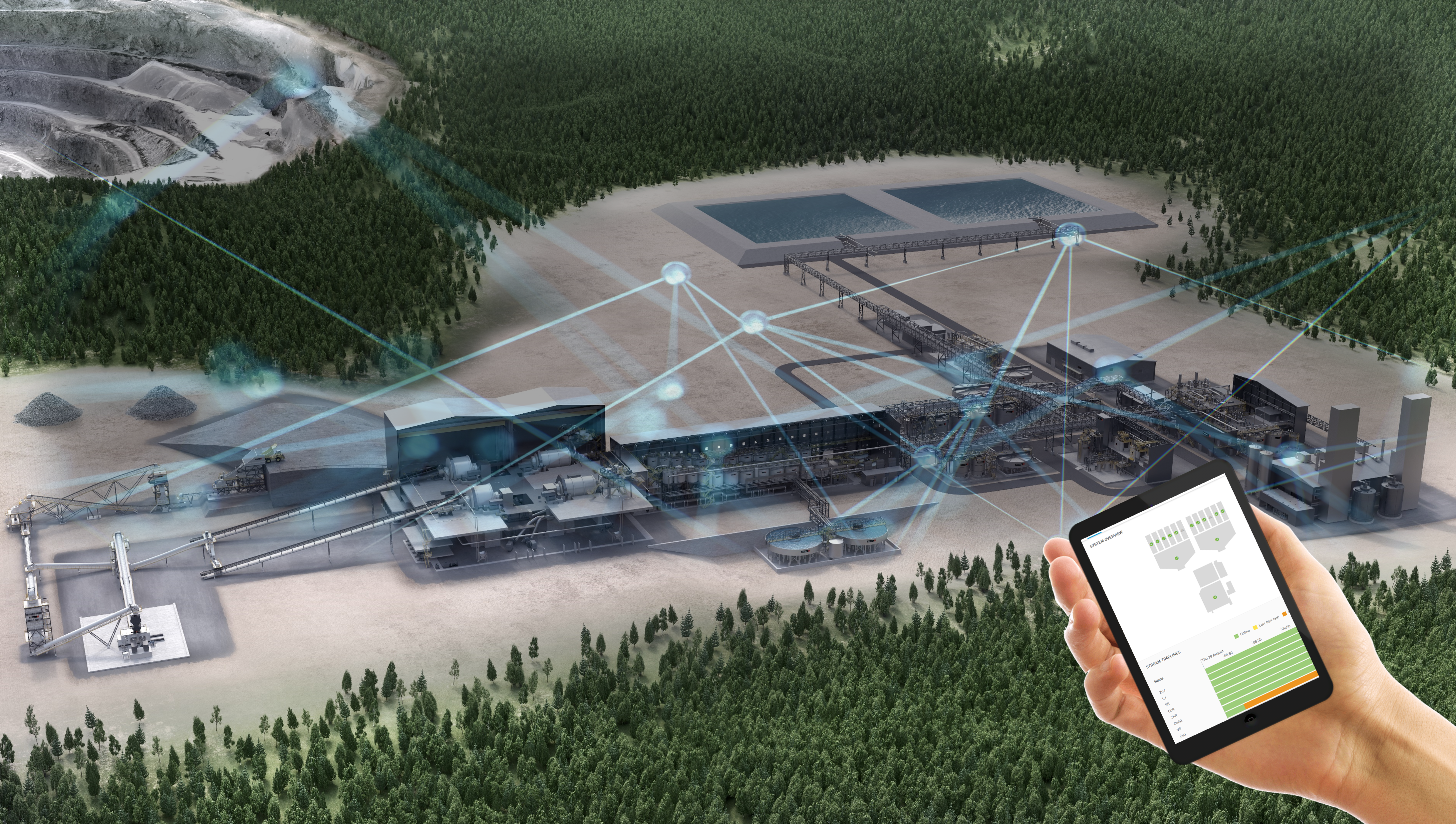

Services made easy and designed for you. Discover our pre-packaged and custom programs

Process engineering experts with over 150 technical papers published

Extensive database of operational insights from over 500 global projects

Products and services that are made to work together seamlessly

Designing and delivering customized performance-based solutions

Optimization can focus on bottlenecks, downstream impact or adapting to market trends and sustainability targets, depending on your goals:

Common during market booms, activities are centered on debottlenecking to improve availability, throughput & recovery.

Whether for one unit or the entire system, activities include reducing energy consumption, chemical cost, water use & adapting to ore types.

Achieving consistent output is key in each stage, the focus is on reducing variability and stabilizing processes across the plant.

Enabling sustainability initiatives while maximizing productivity & profitability.

Blast design has a big impact on process efficiency and site safety. We use tailored modeling and ore tracking tools to help you develop the optimal blast designs for your operation, resulting in improved rock fragmentation while maintaining safe and stable slopes in your mine.

Achieve optimum run-of-mine (ROM), improve downstream plant performance and save on overall energy consumption.

Ore characterization helps build a clear picture of the ore types at the mine and determines how to extract maximum value from your deposit. Ore properties govern the ultimate performance that is achievable in all mining operations.

Achieve improved plant performance and stability with advanced tools and tailored test work programs designed to understand the characteristics and variability of your orebody.

Improve process performance by identifying bottlenecks and areas for improvement in your circuit.

Our thorough evaluation follows a systematic inspection checklist designed specifically for the process or unit in question. This provides a clear picture of current production performance which identifies potential areas for improvement. We then prepare a recommended upgrade path with solid ROI calculations.