Using SmartTag™ - A mine to mill debugging tool webinar

Find out how the SmartTag™ tool can help to pinpoint where production issues lie in real-time in this on-demand webinar

Supporting your operations, from plant design expertise to equipment, parts and services for every stage of your process.

Are you looking to increase production, reduce risks, lower operating costs and enhance environmental performance? Then you are in the right place.

From the design and supply of products for a greenfield plant, to the addition of a single machine for an existing production line, we are here to help.

Rely on OEM experts because not all parts are created equal. Spare and wear parts built to perform.

Helping you get the most out of your equipment and processes.

Intelligent tracking system

Unique Real-time ore tracking from mine to the processing plant and beyond

Increase performance

By implementing pro-active plant control based on incoming ore type.

Process optimization

Link the physical properties of the ore in the mine to the time-based performance data of the plant

Our ore tracking service uses our patented SmartTag™ system to track parcels of ore from the mine into the plant and beyond. SmartTag™ is an innovative system that uses hardened Radio Frequency Identification (RFID) tags, detectors and custom software to track ore through the mining process.

Detection points are located at key points of ore processing. This technology does not require an internal power source, yet the tags have the capacity to main in stockpiles for extended periods.

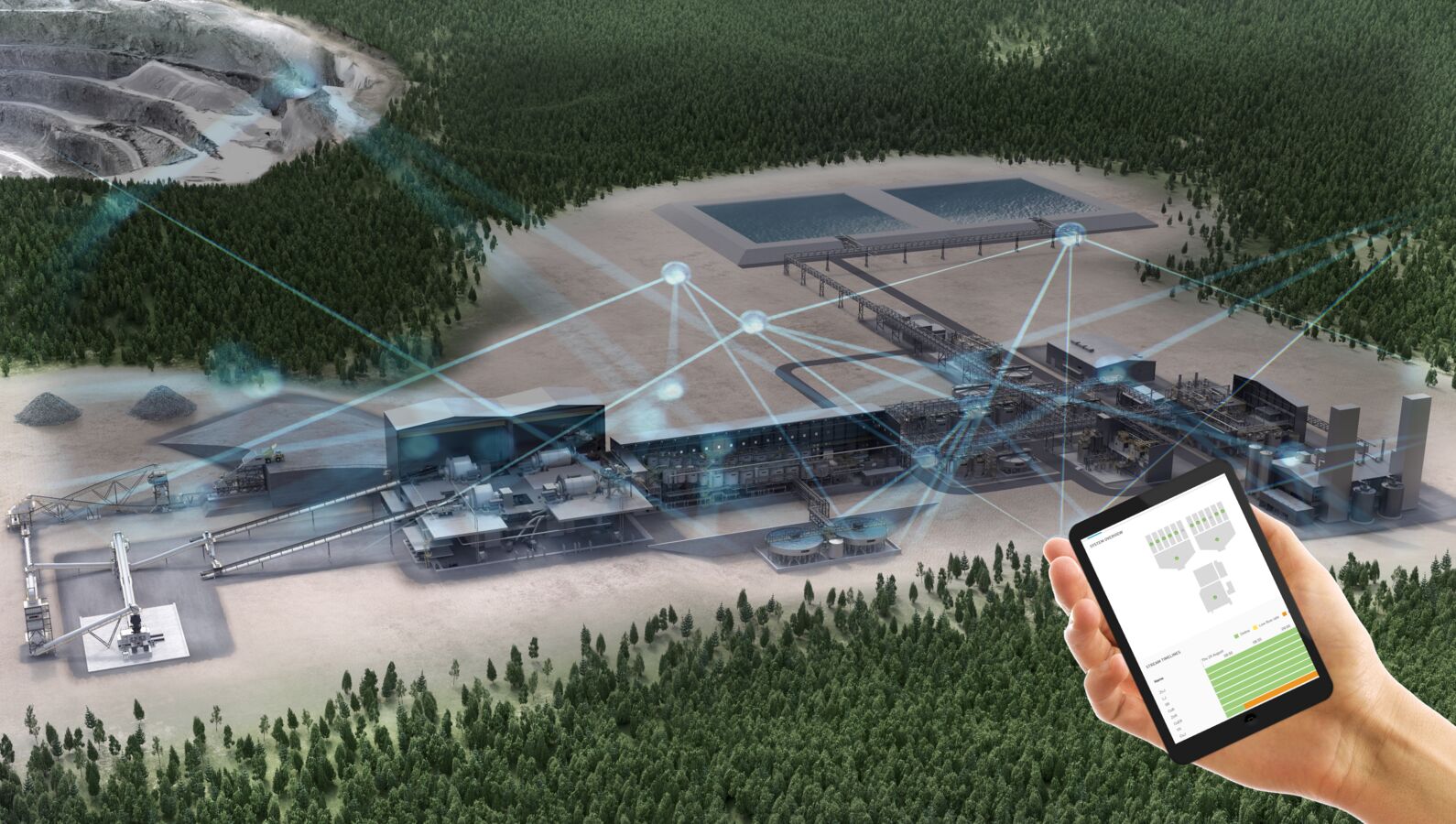

We can correlate ore characteristics with important operating parameters in the mine and processing plant, such as ore dilution, ore losses, fragmentation, throughput and energy consumption. This provides an understanding of how different ores affect mine and plant operation and the final product. Operating parameters and control strategies in the mine and processing plant can be adjusted and optimized for different ore types, thereby reducing costs and increasing profitability.

The SmartTagTM system is also used to automate geometallurgical modeling in our unique GeoMetsoTM system enabling throughput forecasting and Life-of-Mine optimization.

SmartTag™ can also be used to track products from the mine through the entire transport chain (road, rail, and port) to the final customer. This is particularly relevant for iron ore and coal operations which often have complicated product marketing and supply logistics. Any properties can be tagged and tracked to facilitate the optimization of plant operation, sorting, blending, and homogenization to maximize the value of the final product. The system also provides more accurate reconciliation and allows monitoring and optimization of product supply and transport logistics.

Receive regular reports on how processes are performing along with recommendations of action to be taken.