Less safety hazards and higher productivity

Learn how Remote IC has made work safer and more productive at Maansiirto Väinö Tenkanen.

Supporting your operations, from plant design expertise to equipment, parts and services for every stage of your process.

Are you looking to increase production, reduce risks, lower operating costs and enhance environmental performance? Then you are in the right place.

From the design and supply of products for a greenfield plant, to the addition of a single machine for an existing production line, we are here to help.

Rely on OEM experts because not all parts are created equal. Spare and wear parts built to perform.

Helping you get the most out of your equipment and processes.

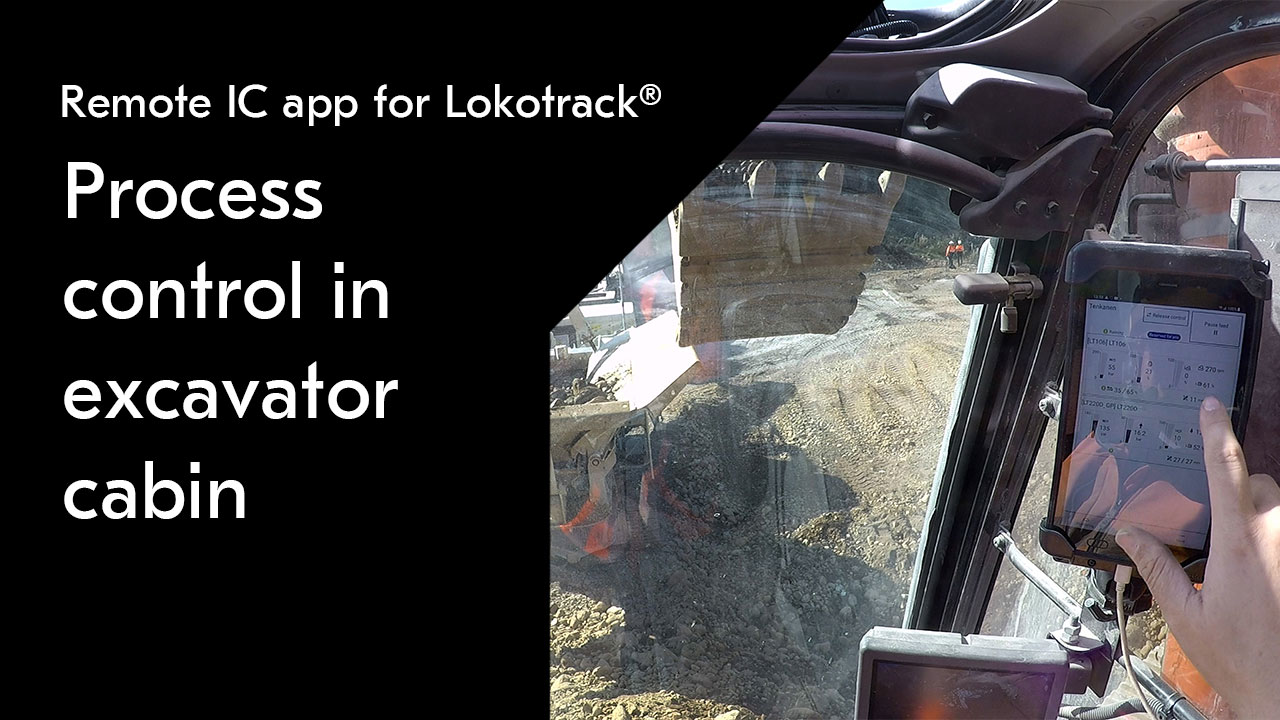

The Remote IC app not only makes work much safer, but also results in a much more productive crushing process with Lokotrack® crushers and screens. Working as an extended monitoring and controlling tool of the existing Metso IC™ process control system, the app gives operator’s visibility to the main parameters of all the machines in the Lokotrack train, all in one single dashboard. Since the operator no longer needs to step out from the excavator cabin as often, using Remote IC lowers the safety hazards at the site.

With an overall visibility of the process, the operator can adjust the feeding for optimal production level. In case of a problem, Metso IC™ process control instantly stops the feeder - thus preventing overloading - and Remote IC alerts the operator on the cause of the stoppage. As a result, this leads to a quicker return to operation. With lower overflow risk, the process can be run closer to the maximum capacity as it helps to avoid process stops.

Wireless network is established within the site and no cables are needed between Lokotrack machines - making moving the machines easier.

The process can be controlled by only one user, but it can be viewed by all the people working at the site so that everyone can see how the process is doing. In case of an alarm, they can go and fix the problem and acknowledge the alarm on the IC display. As Remote IC alerts the cause of the stoppage, it is quicker to locate and fix the problem.

Remote IC not only increases the productivity and safety of the plant, but it can also positively impact the employees’ experience and help attract new skilled workforce.

Remote IC is an app installed on customers’ tablet or mobile phone from Google Play. The Remote IC hardware is available for all new Lokotrack models and can be installed as a retrofit to all models that has the latest Metso Metrics installed.

Try the Remote IC in demo mode by downloading the app here.

You can also search for the app directly in Google Play Store. Type 'Remote IC' and look for the app with this icon

To get your Lokotrack train connected with Remote IC – contact our sales today!