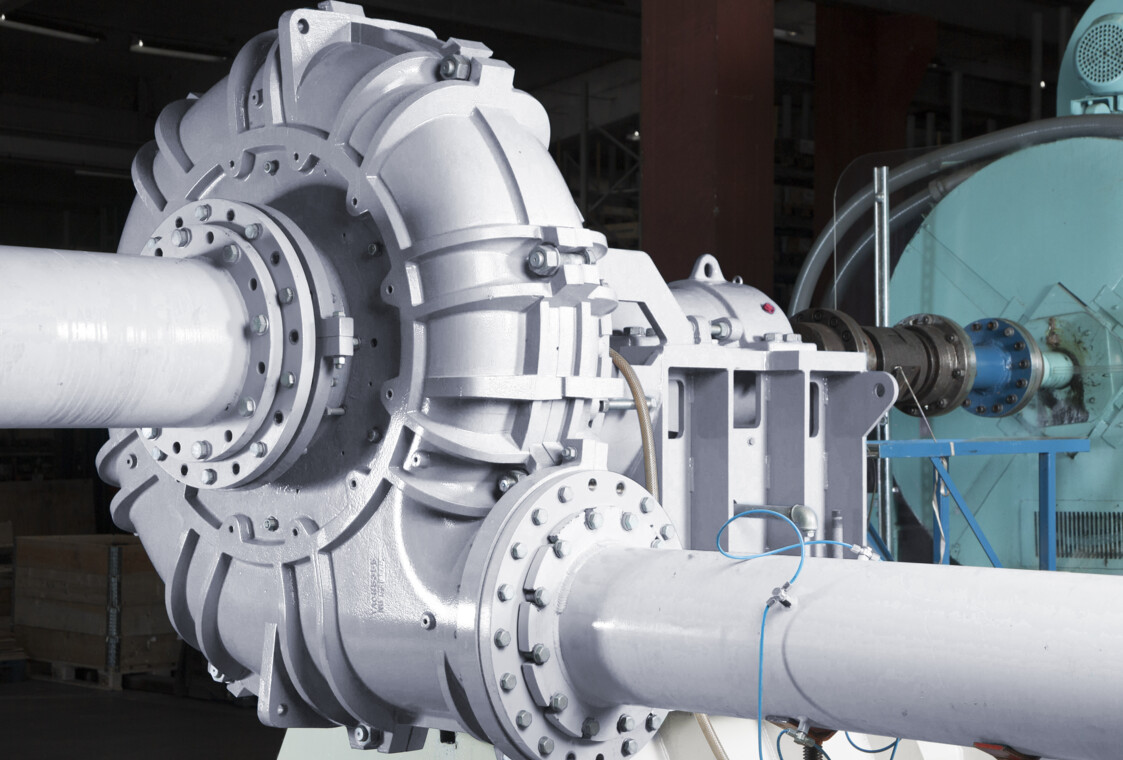

Pumps inspections

Reduce unplanned downtime, minimize equipment failure and lower the risks associated with operating faulty equipment with our inspection packages for your Metso pumps.

Simplicity and predictability

Simplify service and make maintenance costs more predictable.

Higher availability

Maximize uptime by identifying issues early and having spares ready in your inventory.

Maximum pump life

Ensure extended pump life with service and maintenance planning, pump adjustments and reliability engineering.

Global expertise, local support

Pumping professionals in over 60 countries in the world.

By choosing Metso’s Life Cycle Services, you can simplify your maintenance, improve your pump reliability, minimize downtime and maximize pump life.

Unlock the value in your plant

With over 350 Life Cycle Services contracts around the world, we have the experience to deliver consistent value to our partners through our service agreements.

Metso’s track-record also includes the development of many modern mining technologies, so we know how to extend results beyond individual pump performance to ensure that your pumps work in synergy with your other equipment for optimal production and minimized downtime.

With our Life Cycle Services (LCS) we bundle our services into convenient, customizable and easily manageable programs, ranging from the basics to complete solutions, depending on the scale of your needs.

Each package adds additional features, and no matter how basic or how complex your needs, our LCS programs can be customized to help you meet your goals.

1) Rotable program

Simplify service and make maintenance costs more predictable.

2) Inspection and inventory services

Maximize uptime by identifying issues early and having spares ready in your inventory.

3) Equipment maintenance services

Ensure extended pump life with maintenance and maintenance planning, pump adjustments and reliability engineering.

Simplicity and predictability

Rotable pump program optimizes your labor resources, simplifies maintenance, makes maintenance costs predictable and minimizes downtime.

With this program, you keep refurbished pumps (or bearing assemblies) on consignment on your site, so they can be easily changed out when needed.

Metso will take care of each complete pump (rebuilt to OEM specifications), the consignment inventory, wear and spare component replacement labor, as well as pump installation and removal.

Typical benefits

The Inspection and Inventory program improves pump availability and minimizes downtime by identifying issues earlier and ensuring the right spares are available in your inventory.

With this program, Metso takes care of wears and spares consignment inventory and/or supply, scheduled inspections including gland monitoring and adjustment condition monitoring (vibration, bearing temperature, balance), pump performance monitoring, motor and v-belt drive advisory services, as well as extended warranty coverage.

Typical benefits

Our Equipment maintenance services is a complete package that ensures the longest possible working life for your pumps. Our experts will perform the maintenance planning, service work including pump adjustments and engineering.

This program includes everything in the Inspection and inventory services program. The program also adds CMMS and maintenance planning, reliability engineering tools, monitoring of Key Performance Indicators (KPIs), wear and spare component replacement labor, pump adjustments, preventive and corrective labor, and

HSE Planning.

An equipment maintenance services program can be customized to include additional elements including conversion kits, maintenance slide bases and pump wear components and optimization.

The pumps condition monitoring service enhances pump performance by identifying issues early, preventing damage and unplanned downtime. This service maximizes uptime, reliability, and cost efficiency through systematic monitoring using wireless sensors.

It optimizes operations and maintenance schedules, improves safety, and reduces unnecessary maintenance. Additionally, it promotes sustainability by optimizing energy and water consumption, preventing excess wear on components, and minimizing emissions from extra parts.

Real-time data is accessible via a customized dashboard, allowing for remote performance tracking and immediate response to changes.

Read more here >>

Fixed monthly fee

Paying a fixed monthly rate is the standard method available. We mutually predetermine your payment schedules to allow better predictability.

Capex deferral

Deferral plans let you make payments for items like capital equipment, capital tools, wear and spare parts and setup costs at a later date, rather than the date of purchase.

Cost per hour

Cost Per Hour payment plans take cost spikes out of the picture and allow you to be charged based on your operating time during a given month.

Extended warranty

With many of the LCS package options, extended warranties are available, covering the replacement of designated main components.