Highly accurate separation

Adjust easily and accurately to achieve required cut points and high precision.

Low maintenance costs

Intelligently engineered to perform for longer with less required maintenance.

Diverse applications

Effectively classify materials such as fly ash, cement, sand, pozzolan, soda ash, fertilizer and industrial minerals.

Extensive range of options

Gavitational, gravitational inertial, centrifugal, gyrotor, and portable air classifiers.

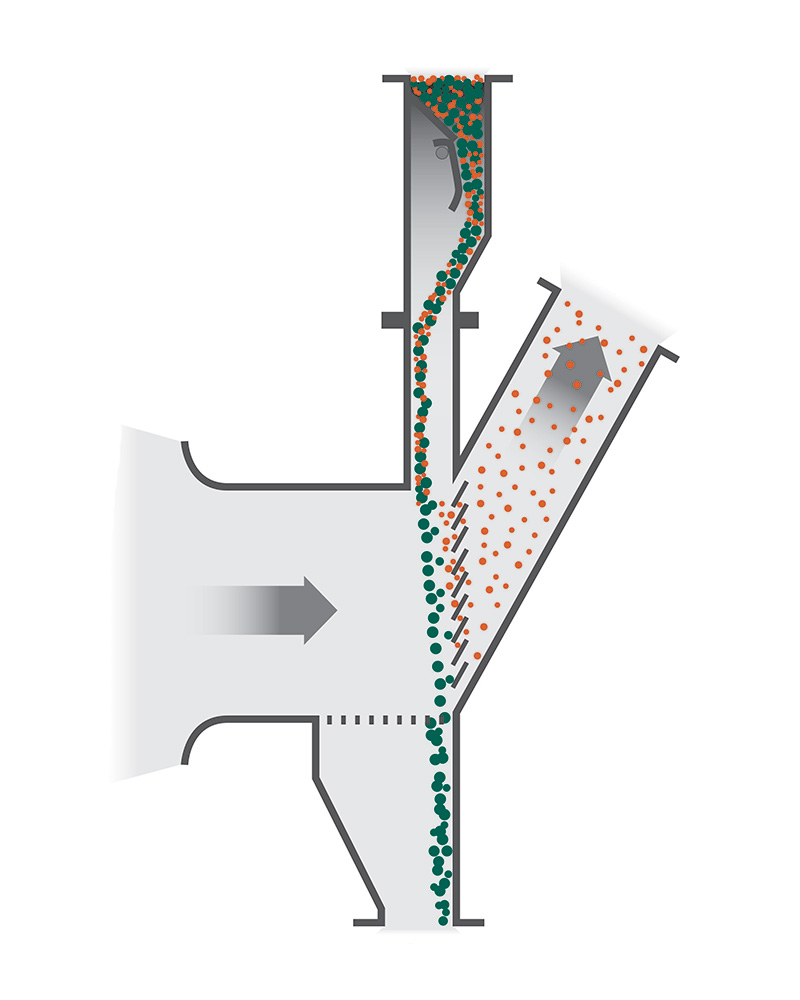

With the use of air flow, gravity and sharp directional changes, the gravitational classifiers perform accurate separations of material from 1,700+ microns down to 150 microns.

Coarse particles are conveyed by gravity through a valve at the bottom of the unit, and fine material is conveyed by air to a fabric filter.

The gravitational air classifiers are effective without the use of water, supporting EPA water-usage regulations.

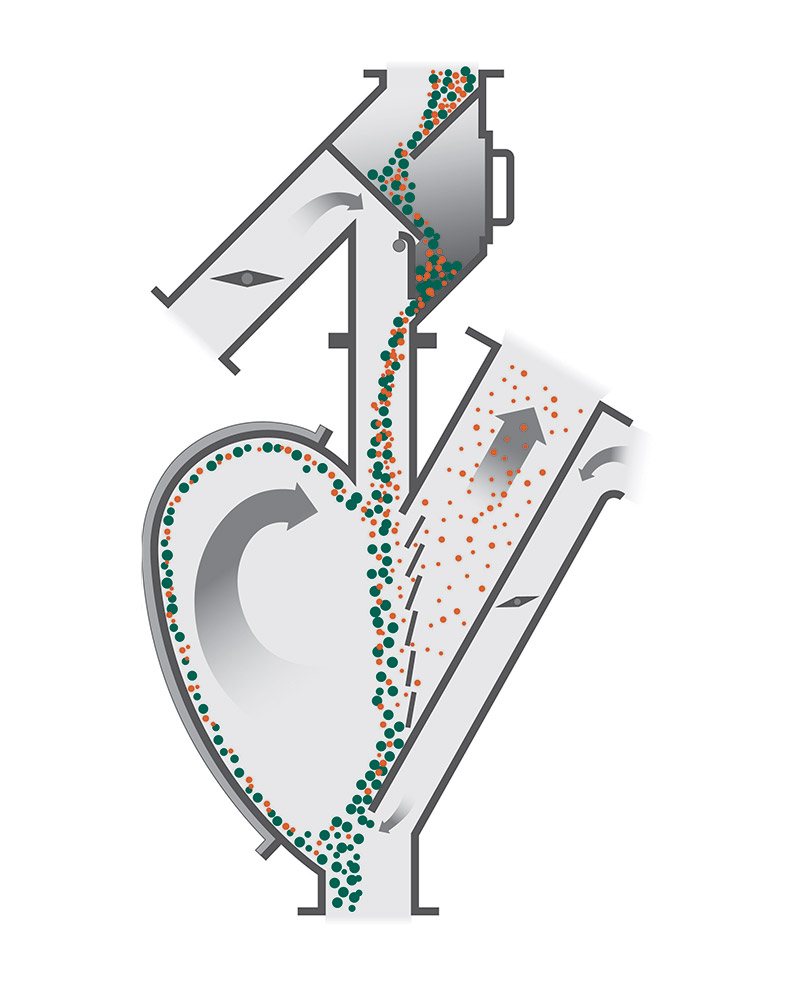

Gravitational inertial air classifiers utilize secondary air flow, along with gravity and sharp directional change, to make adjustable, accurate separations of material from 300 microns to 63 microns.

With no moving parts and extensive use of ceramics in wear areas, the gravitational inertial air classifiers require limited parts replacement and virtually no maintenance.

The gravitational inertial air classifiers are widely used to produce manufactured sand and mineral fillers.

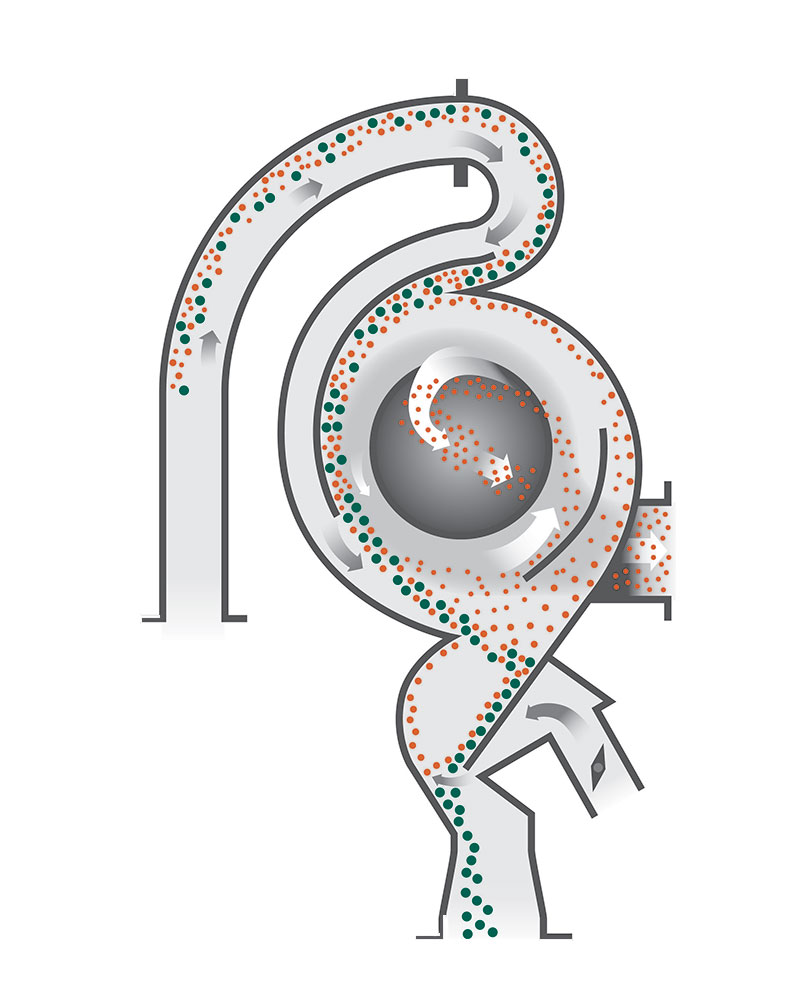

Centrifugal air classifiers use secondary air flow to separate particles ranging from 100 microns to 20 microns.

This air flow, as well as the diameter of the coarse-particles opening, is adjustable – for a clear, accurate cut point. Secondary air flow is also crucial in the removal of near-size particles.

The centrifugal air classifiers are designed to reduce maintenance costs, with ceramic-enforced wear parts and no moving parts.

Centrifugal inertial air classifiers for fly ash processing »

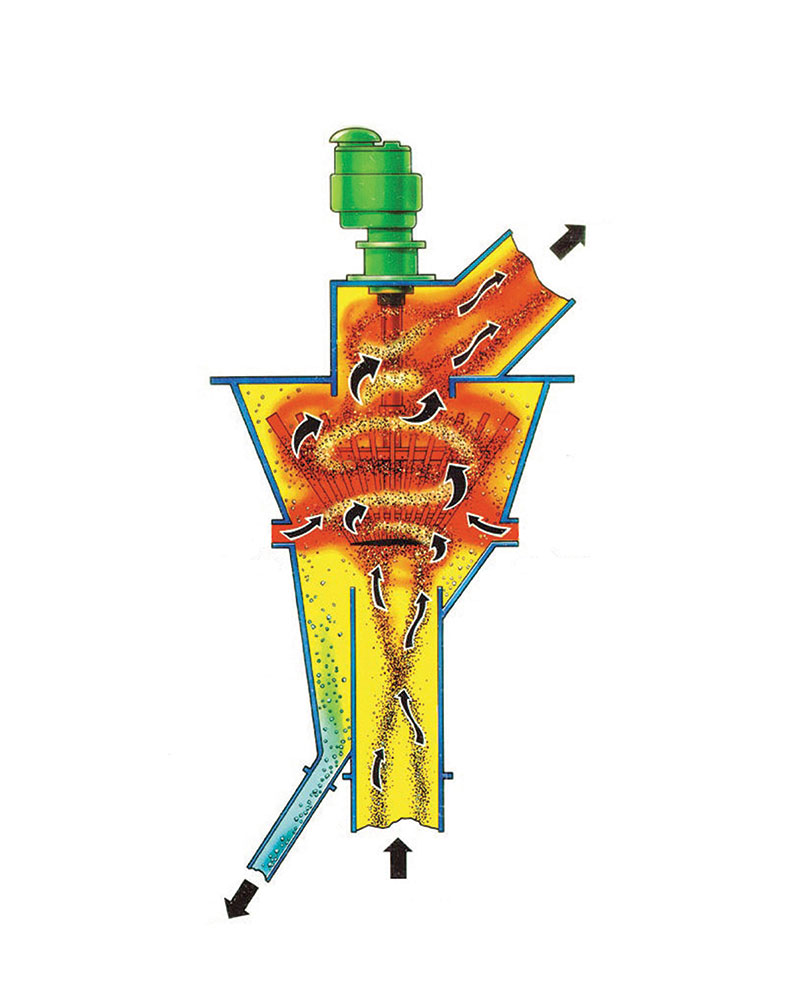

Gyrotor air classifiers, or rotating vane air classifiers, separate dry solid particles by size. They are designed for any separation where the fines are 500 microns (35 mesh) of finer.

They can handle feed rates from 0.1 to 200 tons per hour depending upon the desired cut point and material density.

Intended to be integrated into a conventional closed or open dry grinding circuit, gyrotor air classifiers can also be utilized in a classification only system with cyclone, fabric filter, fan, and rotary air locks.

Gravitational air classifiers and gravitational inertial air classifiers are also available as portable versions.

They are mounted on skids or trailers with wheels for easy transportation and quick setup.

Portable air classifiers use pairs of cyclones to assist in the removal of fine product and can be supported by smaller dust collectors with sufficient cloth to air ratio.