Modular and flexible design.

Up to 70% faster feasibility. Up to 25% faster delivery. Up to 15% faster erection time.

ConveyInsights™, predictive maintenance and flow control.

Known performance, maximum availability.

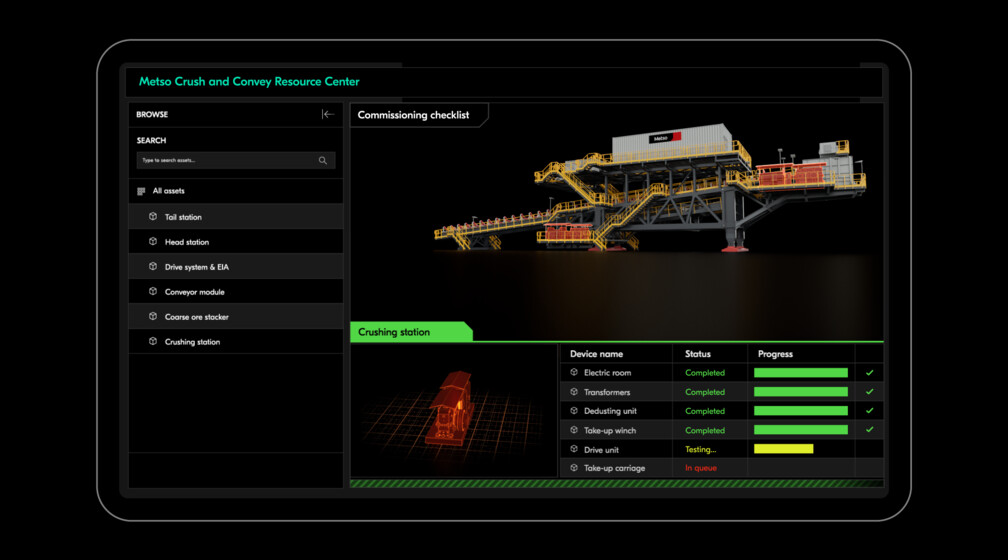

Metso Foresight™ conveyors connect your primary crushing plant to your coarse ore stockpile, leach pad or waste dump. The extensive range of Foresight modules, drive trains and Metso premium components allow you to combine and configure for the capacity, distance and lifts you may require. These productized modules have been designed for ease of transport, assembly, operation and maintenance. Visit the Metso Crush and Convey Resource Center to achieve up to 70% faster feasibility with Metso’s William Conveyor Explorer application software. Size your conveyors, download the relevant models and technical data to instantly assess route options and enhance your planning experience.

Metso FIT™ conveyors used within FIT™ crushing plants are flexible and agile to meet your needs, delivering maximum productivity for the most demanding mining applications. With the use of standard modules and digital solutions, you have access to many combinations of configurations and optimized weights, meeting global safety standards and requirements. The Smart Active Take-up system and an innovative tracking system is bringing the FIT conveyor to a higher level of digitalization. The FIT conveyor is designed using Metso proprietary components, including pulleys, rollers, scrapers and cleaners to maximize availability. ESI idlers are available to help energy savings and reliability of the components.